13

Troubleshooting

The units are manufactured

using state-of-the-art production

methods and tested several times

to verify their correct function.

However, if a functional fault

should occur, the unit should first

be checked in accordance with the

following list.

The unit does not start:

■

Check the hygrostat’s setting

The set value must be lower

than the relative humidity in

the installation room!

■

Check the power supply and

the power fuse provided by the

customer

230V/1~/50 Hz

■

Check the power plug and the

cable for damage

■

Check the condensate tank’s fill

level and seating

The “Container full” indicator

light must not be illuminated!

■

Check that the microswitch

[MS] on the condensate

container is functioning

■

Check that the inlet and outlet

are free

Overheating!

■

Check the fuse on the control

board

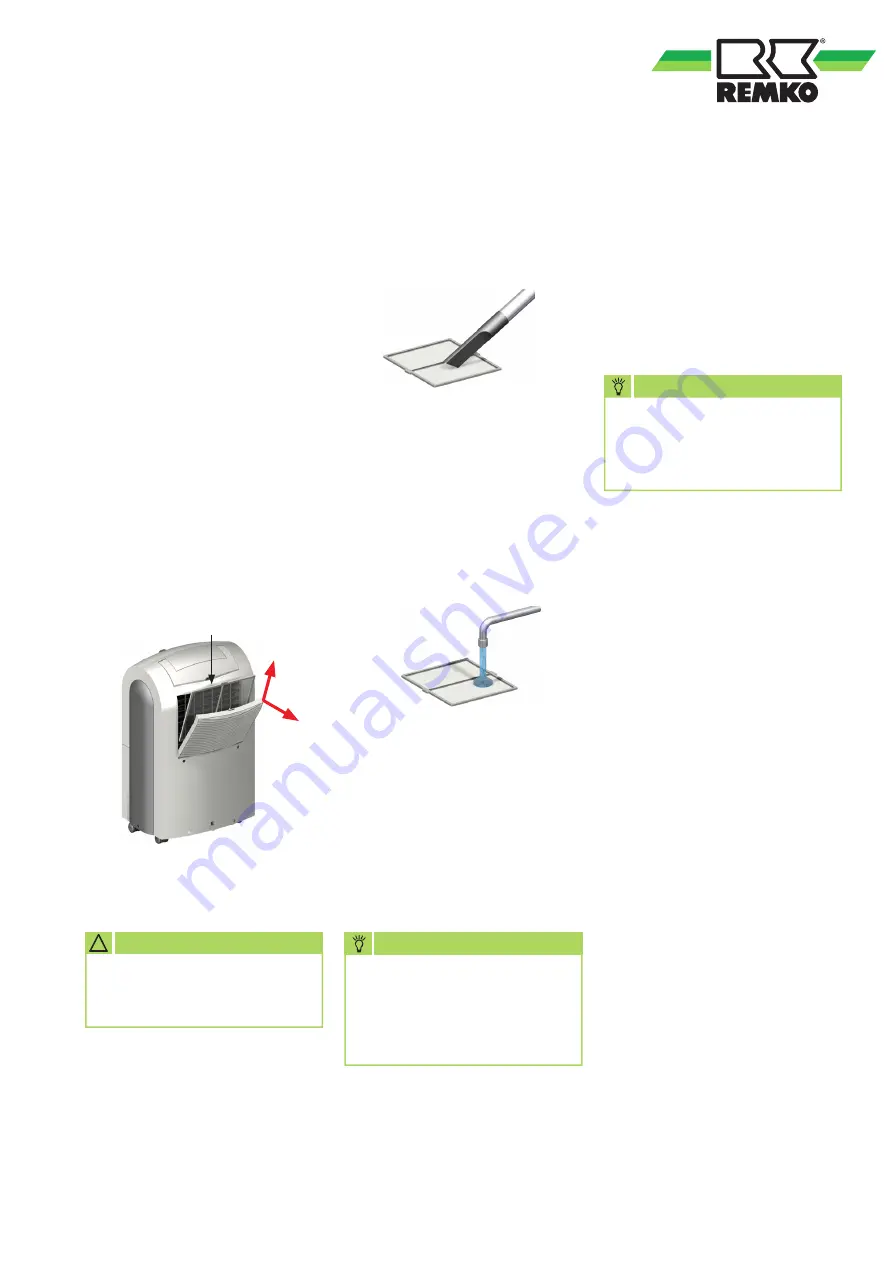

5. Clean the air filter with

lukewarm water or a vacuum

cleaner.

6. Heavier contamination may be

remedied by rinsing the filter in

a lukewarm (max. 40 °C) soap

solution.

Finally, always rinse the filter

carefully with clear water and

allow to dry!

7. Also check the intake grill for

contamination and clean if

necessary.

8.

Before refitting grill and filter,

ensure that they are fully dry

and that no damage has been

sustained.

NOTE

Heavily contaminated or

damaged air filters must be

replaced with new parts.

Only original spare parts may

be used.

NOTE

Adjustment and maintenance

work may only be carried out

by authorised and qualified

technicians.

Filter cleaning

To prevent damage to the unit, it is

equipped with an intake grill with

integrated air filter.

In order to prevent power losses or

unit faults, the intake grill with

filter must be inspected as

required, but every 2 weeks at the

latest, and cleaned if necessary.

1. Use the hygrostat to switch the

unit off.

2. Remove the power plug from

the mains socket.

3. Reach into the recess [G],

push the intake grill backwards

slightly and pull it upwards and

out of the unit’s rear wall.

4. Remove the filter that is behind

the intake grill.

G

s

s

s

The units are not permitted to

be operated without the

intake grill and air filter fitted!

!

CAUTION