14

REMKO ETF 320

The unit runs but condensate

is not formed:

■

Check the room temperature

The operating range of the unit

is between 6 °C and 32 °C

■

Check the humidity of the air

Min. 40 % RH required

■

Check the intake grill and air

filter for contamination

Clean or replace if required!

■

Have the heat exchanger fins

checked for contamination

This work requires the unit to

be opened and must therefore

only be carried out by an

authorised specialist company!

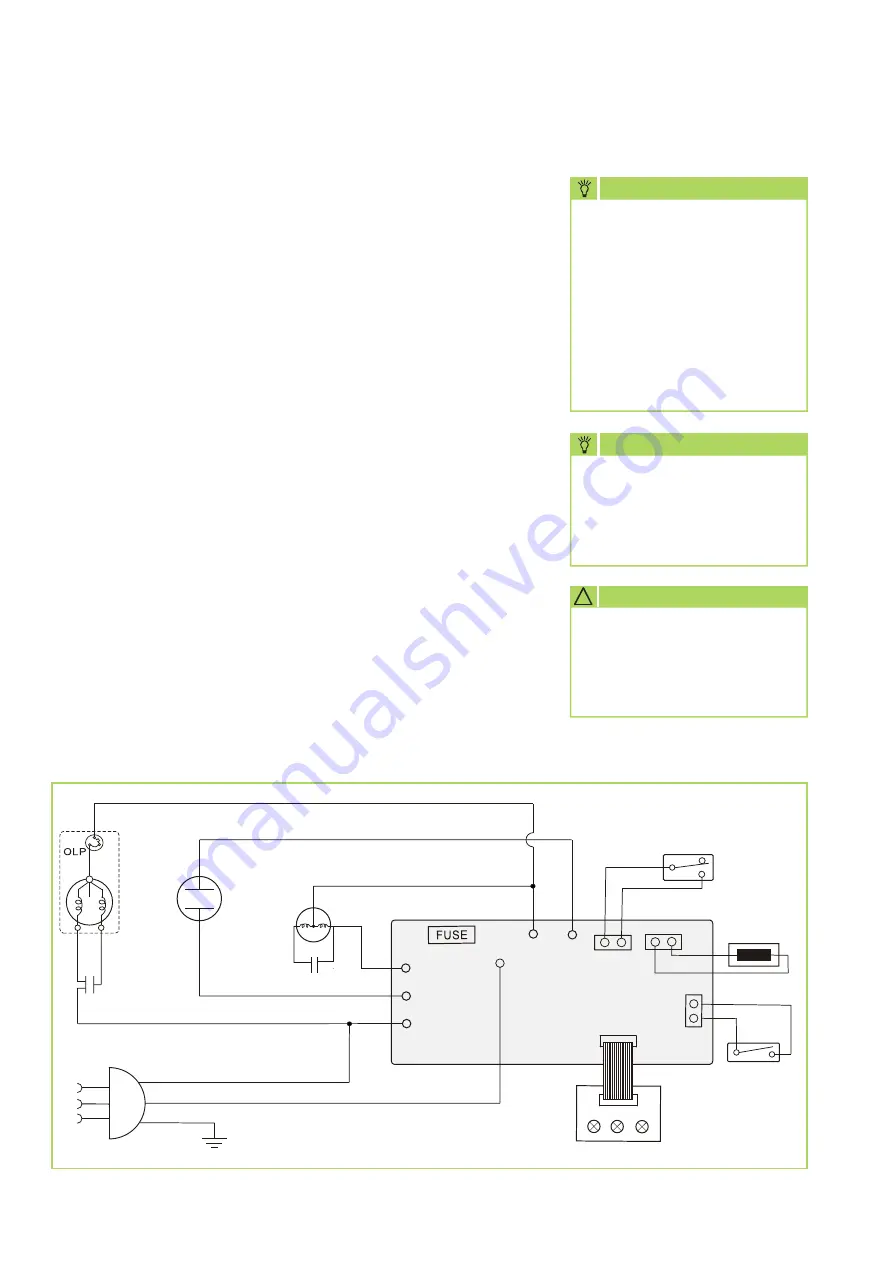

Electrical wiring diagram

NOTE

If the unit fails to function

correctly after the checks have

been carried out, contact an

authorised specialist.

Note

on refrigerants

The units work with

environmentally-friendly

and ozone-neutral R410a

refrigerant.

The mixture of refrigerant

and oil within the unit must

be disposed of properly

in accordance with the

statutory or locally-applicable

regulations.

The unit is loud or

condensate runs out:

■

Check whether the unit is on

a stable and even base

■

Check whether the unit is

standing upright and stably

■

Have the condensate trap or

the connection nozzles checked

to see whether there are dirt

deposits on them

This work requires the unit to

be opened and must therefore

only be carried out by an

authorised specialist company!

s

s

s

P3

P4

P5

P2

P6

P1

CN 4

CN 3

CN 2

CN

5

T3.15AL 250V

Kontrollleuchten

Hygrostat

Mikro-

schalter

Frostschutz-

sensor

ROT

ROT

BLAU

B

LA

U

BLAU

BLAU

BLAU

W

E

IS

S

Kondensator

BLAU

BRAUN

GRÜN/

GELB

PE

23

0V

/5

0H

z

N

L

Ventilator-

motor

Kondensator

W

E

IS

S

B

LA

C

K

K

om

pr

es

so

r

2-Wege

Magnet-

ventil

Work on the refrigerant

system and on the electrical

equipment must only be

conducted by a specially-

authorised specialist!

!

CAUTION

RED

BLUE

BLUE

BLUE

BLUE

BLUE

BROWN

GREEN/

YELLOW

WHITE

BLACK

2-way

solenoid

valve

Fan motor

Microswitch

Antifreeze

sensor

Hygrostat

Indicator lights

Condenser

Condenser

Compressor