9

Commissioning the units

1. Turn the hygrostat’s

rotary knob

anticlockwise into

the “OFF” position.

2. Connect the unit's

electrical connection

to a properly

installed mains

socket.

3. Open the air flap on the top

of the unit.

4. Preselect the

desired air humidity

for the installation

room on the

hygrostat.

The recommended approximate

setting values are listed in the

adjacent section.

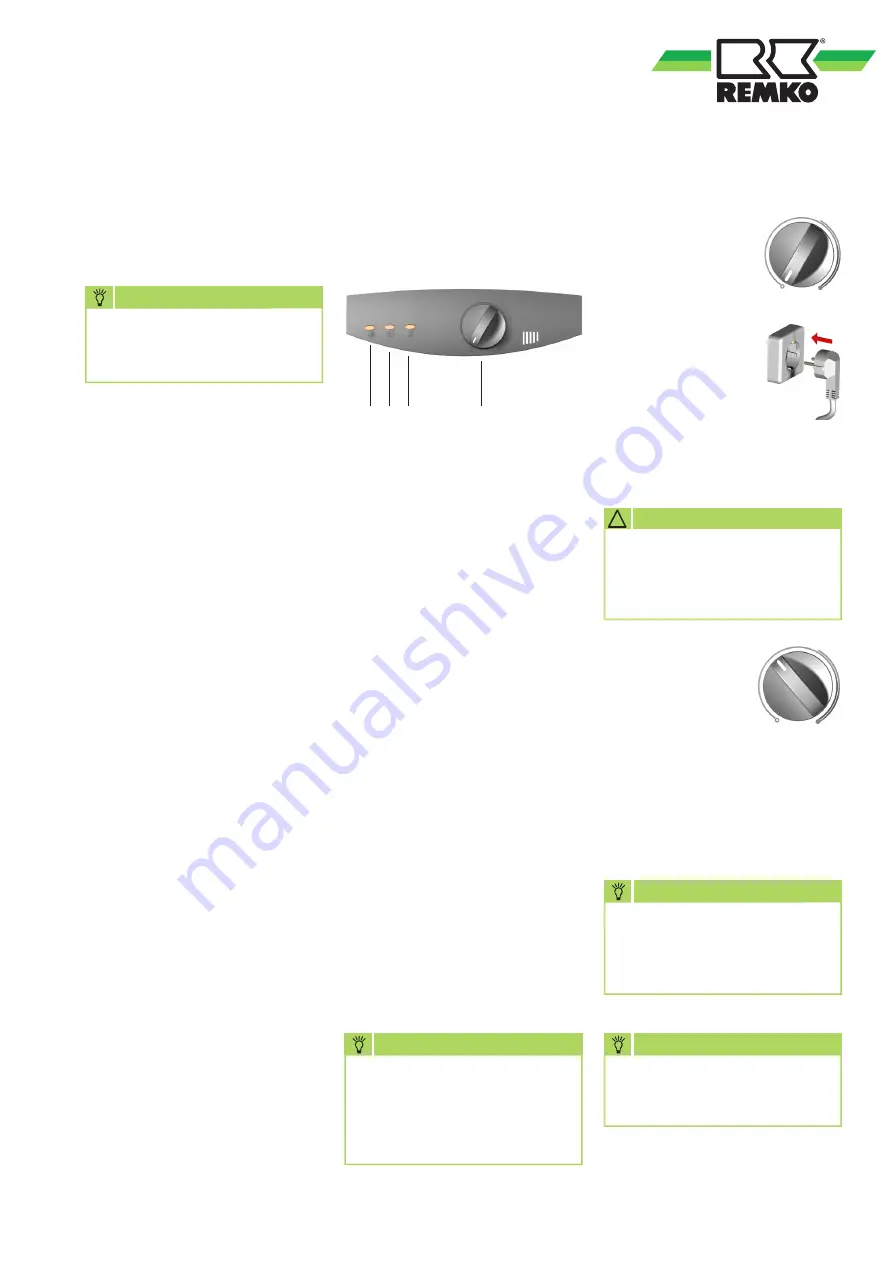

Commissioning

Control panel

The hygrostat’s rotary knob and

the indicator lights are located on

the control panel.

➊

Hygrostat

The infinitely adjustable

hygrostat can be used to select

the required air humidity in the

installation room.

➋

“Dehumidification” indicator

light

This light indicates that

the unit is operating correctly.

➌

“Container full” indicator light

This light indicates that the

condensate container is full and

must be emptied.

➍

“Defrost mode” indicator light

This light indicates that the

automatic defrost system that

is integrated in the unit has

switched on the defrost cycle.

NOTE

In room temperatures below

10 °C

and relative humidity

below

40 %

, economical use

of the unit can no longer be

guaranteed.

NOTE

Note that the compressor does

not switch on until a waiting

time of 3 minutes has elapsed.

Restart protection!

NOTE

The devices can be switched

ON and OFF via an external

time (accessory) if required.

Before commissioning the unit

or if local requirements dictate,

the air-inlet grill and air-outlet

grill must be checked for

contamination.

Important notes prior

to commissioning

■

All extensions to the electrical

connection must be of

a sufficient cable size and must

only be used fully rolled out or

unrolled

■

Never use the mains cable

as a pull cord

■

After being switched on,

the units operate fully-

automatically until switched off

by the hygrostat or float when

the condensate container is full

■

The condensate container must

be inserted properly

The unit cannot be operated if

the condensate container is not

inserted properly!

■

In order to prevent damage to

the condenser, the units are

equipped with a mechanism

that prevents the compressor

being immediately switched

back on after it is switched off

The units do not switch back

on until a waiting time of

around 3 minutes has elapsed!

■

If the units work in continuous

operation with an external

condensate drainage

connection, refer to the

relevant section

NOTE

A contaminated grille or filter

must be cleaned or replaced

immediately.

s

s

s

➊

➋

➌

➍

The units are only permitted

to be operated with the air

flap open in order to prevent

overheating.

!

CAUTION