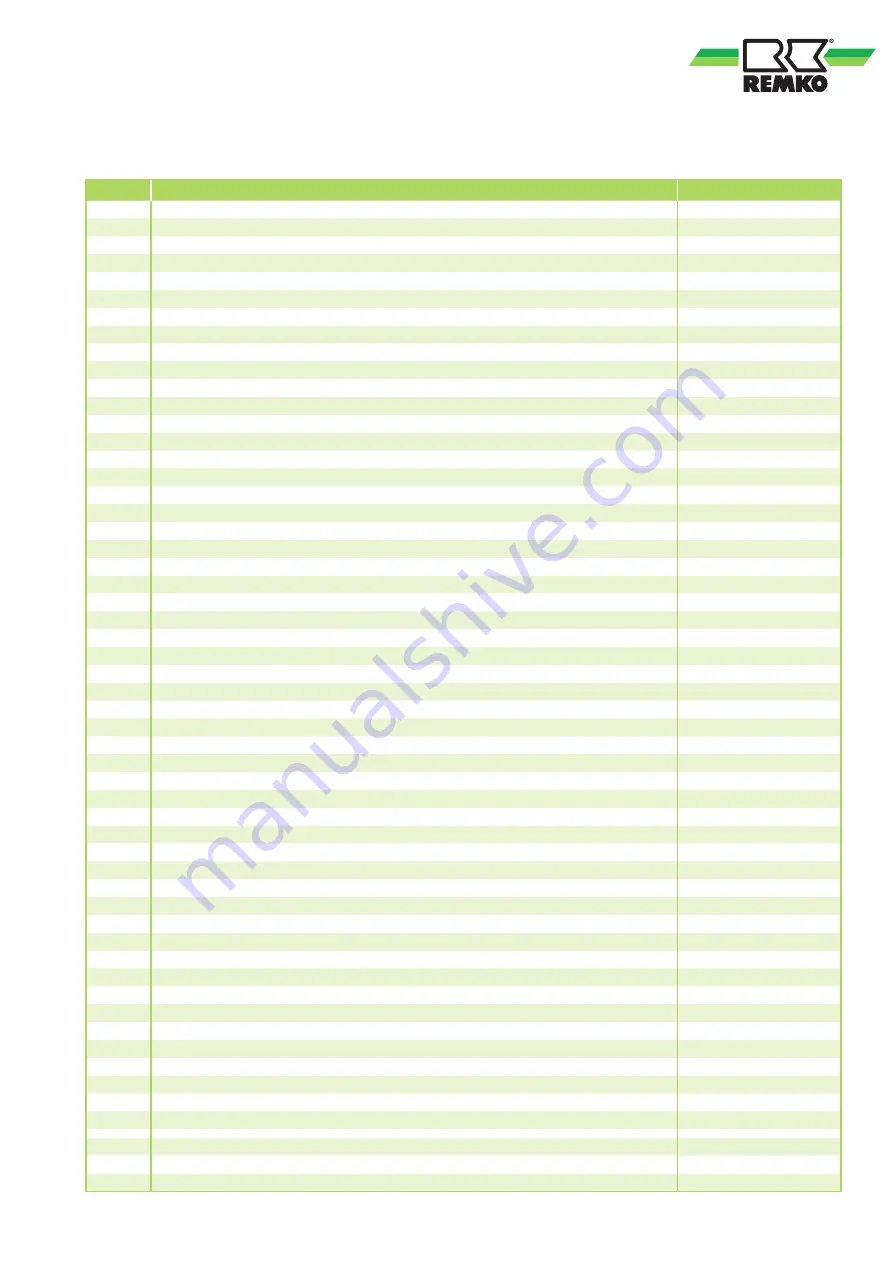

17

Spare parts list

When ordering spare parts, please state the EDP no., unit number and type (see name plate)!

no.

Description

HTL 80

HTL 170

01

Cover panel

1104740-1

1104851

02

Upper insulation

1104741-1

1104852

03

Insulation right / left

1104742

1104853

04

Upper side cover (right / left)

1104743

1104854

05

Lower side cover (right / left)

1104744-1

1104855

06

Lower insulation

1104746

1104872

07

Base tray, front

1104745

1104856

08

Base tray, rear

1104836

1104857

10

Front wall cmpl.

1104755

1104858

11

Front wall insulation

1104756

1104786

12

guide bracket

1104757

1104787

13

Hose pass-through

1104722

1104722

20

Multiflex oil pre-heating, compl.

1071411

1071411

21

O-ring

1108464

1108464

22

Filter insert

1108462

1108462

23

Oil filter cup

1108463

1108463

24

Oil filter, compl.

1002526

—

25

Outlet nozzle

1104758

1104788

26

Burner cladding cmpl.

1104759

1104789

27

Transport skids (set)

1002528-1

1002529-1

30

Combustion chamber, cmpl.

1104761-2

1104806-2

31

Exhaust gas suppressor (set)

1104793

1104810

32

Inspection cover

1104763

1104794

33

Seal for inspection cover

1104764

1104795

34

Sealing cap

1104728

1104784

35

Centre wall

1104841

1104862

36

Intake grill, right / left

1104842

1104863

40

Back wall

1104843

1104864

41

Switching cabinet cmpl.

1104783-1

1104865

42

Seal for switching cabinet

1104754

1104866

43

Crane eye

1102554

1102554

44

Exhaust gas nozzle collar

1104732

1104796

45

Transportation bracket, front

1104765

1104867

46

Transportation bracket, middle

1104767

1104868

47

Transportation bracket, rear

1104766-1

1104869

48

Spacing roller

1104849

1104849

50

Radial fan

1108603

1108607

51

Fan belt pulley

1113111

1102777

52

V-belt

1113112

1102774

53

Motor belt pulley

1113110

1102784

54

Electric motor IE2

1102737

1102733

55

Motor bracket with clamp

1104850

1104870

60

Temperature controller (TR)

1103166

1103166

61

Safety temperature limiter (STB)

1101197

1101197

62

Temperature monitor (TW)

1103146

1103146

66

Operating switch

1101188

1101188

67

Indicator light, green (Operation)

1105514

1105514

68

Indicator light, red (Burner fault)

1105363

1105363

69

Reset button (Burner)

1103408

1103408

70

Thermostat receptacle

1101018

1101018

71

Strapping plug

1101019

1101019

72

Mains cable with plug

1104701

1105100

Not shown

Burner connector, 7-pole

1102537

1102537

Not shown

Drum fitting, cmpl.

1002544

1002544

Not shown

Cleaning brush, cmpl.

1103110

1103110