Care and maintenance

Shut-down

Temporary shut-down

1.

Shut down the interior of the

system using the remote

control.

2. Shut the unit down either by

the internal controller or by us-

ing the remote.

3. Check the proportion (percent-

age) of glycol.

4. Check the unit for visible signs

of damage and clean it as

described in the chapter “Care

and maintenance”.

5. As much as possible, cover the

unit with a plastic foil to protect

it against the weather.

If only water and not a mix-

ture of water and glycol

is used, in regions subject

to freezing, water must be

drained from system when

it is not in operation The

drained water volume must be

replaced when system is put

back into operation!

!

CAUTION

Permanent

shut-down

Ensure that equipment and com-

ponents are disposed of in accord-

ance with local regulations, e.g.

using certified firms and recycling

specialists or at collection points.

REMKO GmbH & Co. KG or your

contractual partner will be pleased

to provide a list of certified firms in

your area.

Regular care and maintenance of

the system will ensure trouble-free

operation and a long service life.

Prior to performing any work,

The system must be switched

off and isolated from the

power supply and secured to

prevent accidental switch-on!

!

CAUTION

Wearing appropriate protec-

tive clothing is necessary when

working on the system.

!

CAUTION

Care

■

Ensure the unit is protected

against dirt, mould and other

deposits.

■

Clean the unit using a damp

cloth. Do not use a jet (high

pressure).

■

Do not use any caustic, abra-

sive or solvent-based cleaning

products.

■

Clean the fins on the unit prior

to long shutdown periods.

Maintenance

■

We recommend an annual

maintenance contract with an

approved specialist company.

This ensures the operational

reliability of your system!

TIP

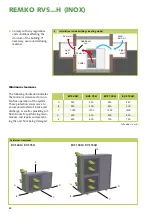

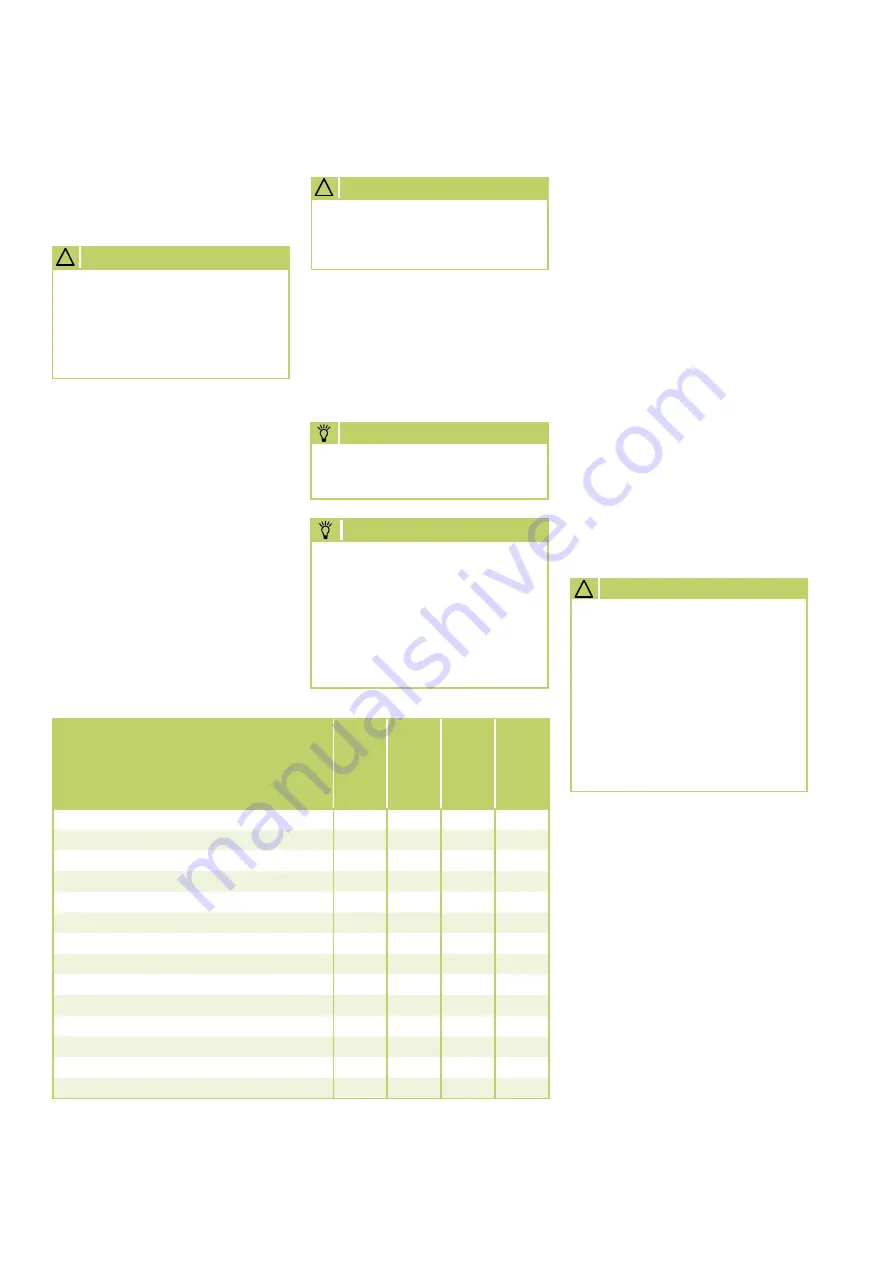

List of task

Checks / maintenance / inspection

Commis

-

sioning

Monthly

Half-yearly

Yearly

General

•

Clean dirt traps

•

•

Check medium charge

•

•

Check circulation pump

•

•

Dirt / damage condenser

•

•

Check quality of the glycol

•

•

Measure voltage and current

•

•

Check direction of rotation

•

•

Check compressor

•

•

Check fan

•

•

Check refrigerant charge

•

•

Check condensation drain

•

•

Test insulation

•

•

Leak test for refrigerant cycle

•

•

1)

The local law can require a

leak test of the cooling system

and the quantity of cooling

medium to be checked. In-

spection and documentation is

to be carried out by qualified

personnel.

NOTE

1) see note

REMKO RVS...H (INOX)

14

Summary of Contents for RVS 100H INOX

Page 2: ......