The system has been manufactured using state-of-the-art production methods and in house tested many times to

ensure the system is 100% in working order. If malfunctions should occur, please check the system as detailed in

the list below. For installations with an indoor-outdoor system, observe the chapter “Trouble-shooting and customer

service” in both operating manuals.

Please inform your dealer if the system is still not working correctly after all the function checks have been per-

formed.

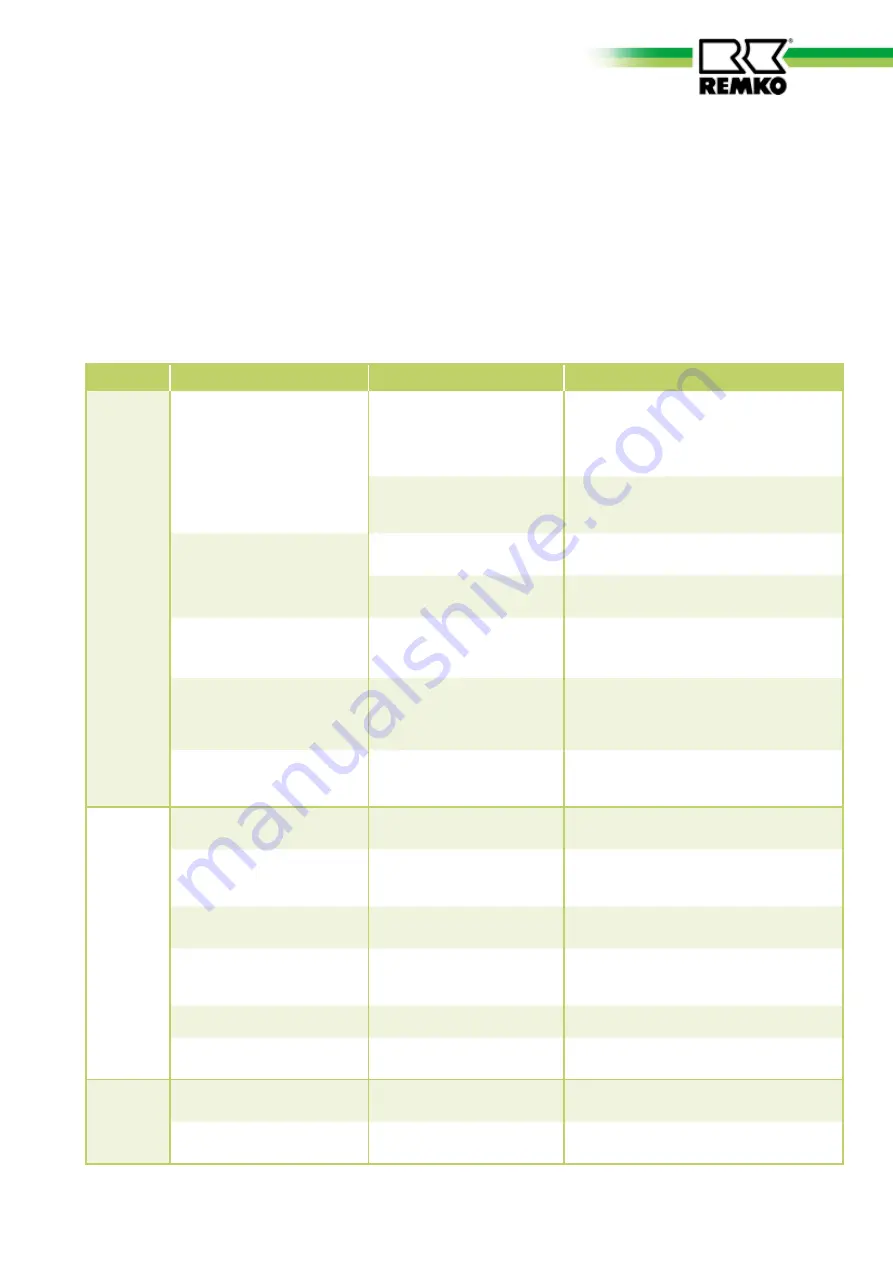

Touble-shooting and customer service

Malfunctions

Please note that this trouble-shooting table continues on the next page

Fault

Possible cause

Check

Remedial measures

The unit

does not

start

Display is not illuminated.

No power supply

Check the power connections at the mains

and the voltage values.

Check breaker switches/fuses at the second-

ary side of the supplemental transformer.

Incorrect phase sequence.

The KA3 phase sequence relay

did not enable.

Replace power supply phase conductorat the

at the terminal strip on the switch panel.

The display is illuminated but

the unit does not start.

Unit in STAND BY

See paragraph "Key functions" for the acti-

vation of the unit.

No external enabling contact

is shortened

Check connection to the GND - ID5 termi-

nals.

The unit does not start, the

compressor icon in the display

is blinking.

Start-up delay

Wait out the start-up delay (max 360 sec.),

the compressor should then start.

The display blinks and

alternately shows an

alphanumeric code and the

temperature value.

One or more protective

devices have responded

Check which safety device has responded,

correct the cause of the fault and reset the

safety device (see "Fault display by code")

Compressor overload switch is

activated.

Does the compressor icon light

up and does the switch have

voltage?

Have specialist replace switch or compressor.

The unit

is work-

ing with

reduced

cooling/

heating

capacity

Thermal load was increased.

Have there been any structural

changes?

Maintain safety clearances.

Supply temperature too high

(cooling) / too low (heating).

If the medium outlet tempera-

ture is approx. 5 ... 10 °C /

35 ... 40 °C?

Increase/reduce medium intake temperature.

Air in the medium cycle.

Are automatic bleeders in-

stalled at the highest point?

Bleed manually or install automatic bleeders.

Condenser / evaporator tem-

peratures too high (cooling) /

too low (heating).

Are the fins clean / free of ice

and the operating limits

complied with?

Comply with operating limits

Cooling: Clean fins, provide shade for the

unit, heating: Reduce supply temperature

Incorrect parameter setting.

Check setting.

Change setting.

Pulse mode because of too

little demand.

Is the system oversized?

Increase medium flow with the installation of

a storage tank.

Medium

discharge

Leak in the lines or insulation

defective.

Are there leaks and are all of

the lines insulated?

Seal and insulate.

Defrosting phase in heating

mode.

Heating mode set?

Normal operating status.

15

Summary of Contents for RVS 100H INOX

Page 2: ......