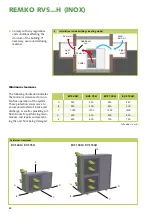

Minimum/maximum medium flow

The circulating pump generates a

constant medium flow; the result

is a loss of pressure in the system

and in the chiller.

The flow switch in the chiller

measures the medium pressure loss

over the evaporator and switches

the unit off if the minimum

medium flow is to low.

The medium flow limit may not

be exceeded (maximum medium

flow).

A Three-way-valve with bypass

and a hydraulic switch to establish

a primary and secondary cycle or a

volume dependent bypass is nec-

essary to ensure a constant flow

volume.

Valve for hydronic balancing

The calculated individual

pressure losses in the pipeline

network layout for each individual

unit are adjusted to the entire

system with the valves for

hydronic balancing to be provided

on-site. The nominal flow volumes

for the medium adjust to the

necessary values as a consequence

of the pressure loss.

Pressure gauge and thermometer

The pressure gauge and thermom-

eter to be installed on-site at

the intake and outlet serve to set

the medium flow. The display

should mean shut down In the

system there are temperature

sensors in the medium intake and

medium outlet.

The temperature at the probes can

be seen on the controller.

Medium lines

Medium lines can be made of cop-

per, steel or plastic. To minimise

pressure losses, only straight flow

through fittings should be used.

When designing the layout it must

be taken into account, the large

flow volumes in the systems, high

pressure losses in connection with

water-glycol mixtures and the

chiller’s minimum medium flow.

The lines are to be insulated

against vapour density and the

current Energy- Savings-Regu-

lations (EnEV) or other local law

must be observed. UV resistance

material must be used outdoors.

During use and disposal,

product and safety data sheets

for the glycol type being used

as well as applicable local

regulations (e.g. Water

Resources Law) must be

observed.

!

CAUTION

Use the required type and

mixture to set the antifreeze

setpoint.

!

CAUTION

To regulate the circulation pump

we recommend a main valve

for hydraulic balancing near the

unit.

NOTE

Minimum medium volume of the

system

A minimum medium volume in the

system may not fall below

3.5 l/kW per power stage.

Ensuring the minimum medium flow

Correct

installation

Incorrect

installation

2-way

valve

3-way

valve

Frost protection (accessories)

As a medium for a chilled water

system, a water-glycol mixture

is used as a rule. Depending on

the use to which the glycol type

and quantity is put, the viscos-

ity changes, the loss in pressure

increases and the unit’s cooling or

heating capacity reduces. All sys-

tem components must be suitable

for use with glycol.

As a rule, the addition to the water

of ethylene glycol, in a proportion

of 34%, with inhibitors for corro-

sion protection is recommended.

23

Summary of Contents for RVS 100H INOX

Page 2: ......