Configuration antifreeze protection parameters

It can be necessary to reconfigure the antfreeze protection parameters

when using a water-glycol mixture. Under menu item -

A-

the parameter

A 01 can be changed within the limits of parameter A 04 and A 07.

Factory setting:

Activation antifreeze protection fault Parameter A 01 =

+2.0 °C

Upper antifreeze protection setting

Parameter A 04 =

+4.0 °C

Lower antifreeze protection setting

Parameter A 07 =

- 40.0 °C

The following program sequence must be programmed.

The following values must them be input:

Configuration parameter Ar 03

0% Ethylene

glycol

(Factory setting)

10 % Ethylene

glycol

(Password)

20 % Ethylene

glycol

(Password)

30 % Ethylene

glycol

(Password)

35 % Ethylene

glycol

(Password)

Value A 01

4°C

0°C

-4°C

-13°C

-17°C

short-term

short-term

short-term

min. 5 sec.

+

...

repeated

short-term

short-term

short-term

short-term

+

Propor-

tion

glycol

Antifreeze

protection

+-2°C

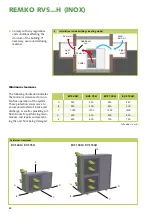

Correction factors when using

a mixture of glycol* and water

Cooling

output

Compressor input

Cooling Heating

Medium

flow

Pressure

loss

Vol. %

°C

K

L

K

P cooling

K

P heating

K

V

K

D

0

0

1

1

1,012

1

1

20

-9

0,981

0,988

1,012

1,040

1,19

35

-21

0,971

0,982

1,018

1,090

1,35

40

-26

0,968

0,981

1,019

1,105

1,51

*

We recommend using an ethylene glycol mixture. Observe the safety and product data sheets

for the glycol type being used.

This mixture ensures frost protec-

tion to –20°C; at lower tempera-

tures, an ice porridge forms which

has no more expansion effect.

The toxicologically harmless

propylene glycol should be used if

there is a risk that the medium can

come into contact with drinking

water or food stuffs. To maintain

the expansion effects, a proportion

of 38% is necessary as a rule

Diaphragm expansion vessel

To avoid pressure fluctuations

during non circulation because of

temperature changes, expansion

vessels filled with nitrogen (moisture

neutral) must be integrated in the

system.

The unit’s standard equipment

includes one expansion vessel. The

preliminary pressure must be set on

the system; an increase in volume

or, in the event of a cooing-heating

system, the installation of another

expansion vessel may be necessary.

Safety valve

Safety valves limit excess operating

pressure due to over heating or

overfilling of the operating me-

dium. The valve outlet requires

unobstructed drainage into a drain

pipe. Applicable local disposal

regulations must be observed if

glycol is used.

The standard scope of delivery for

the unit includes a safety valve; an

additional valve may be necessary.

Compensators

Compensators are used to connect

lines to the unit to prevent

vibration in the system from been

transmitting to other parts of the

system.

Compensators

Ball valve

Compensator

Structural

fastening

unit connection

REMKO RVS...H (INOX)

24

Summary of Contents for RVS 100H INOX

Page 2: ......