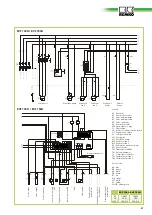

Electrical components

Electric components and safety

equipment

Pressure switch cooling cycle HP

and LP

There is a high pressure switch

(HP) on the heat gas side within

the cooling cycle to switch off the

unit in the event of a temperature

increase.

A low pressure switch (LP) on the

suction side or in the compressor

switches off the unit if the

refrigerant charge is too low.

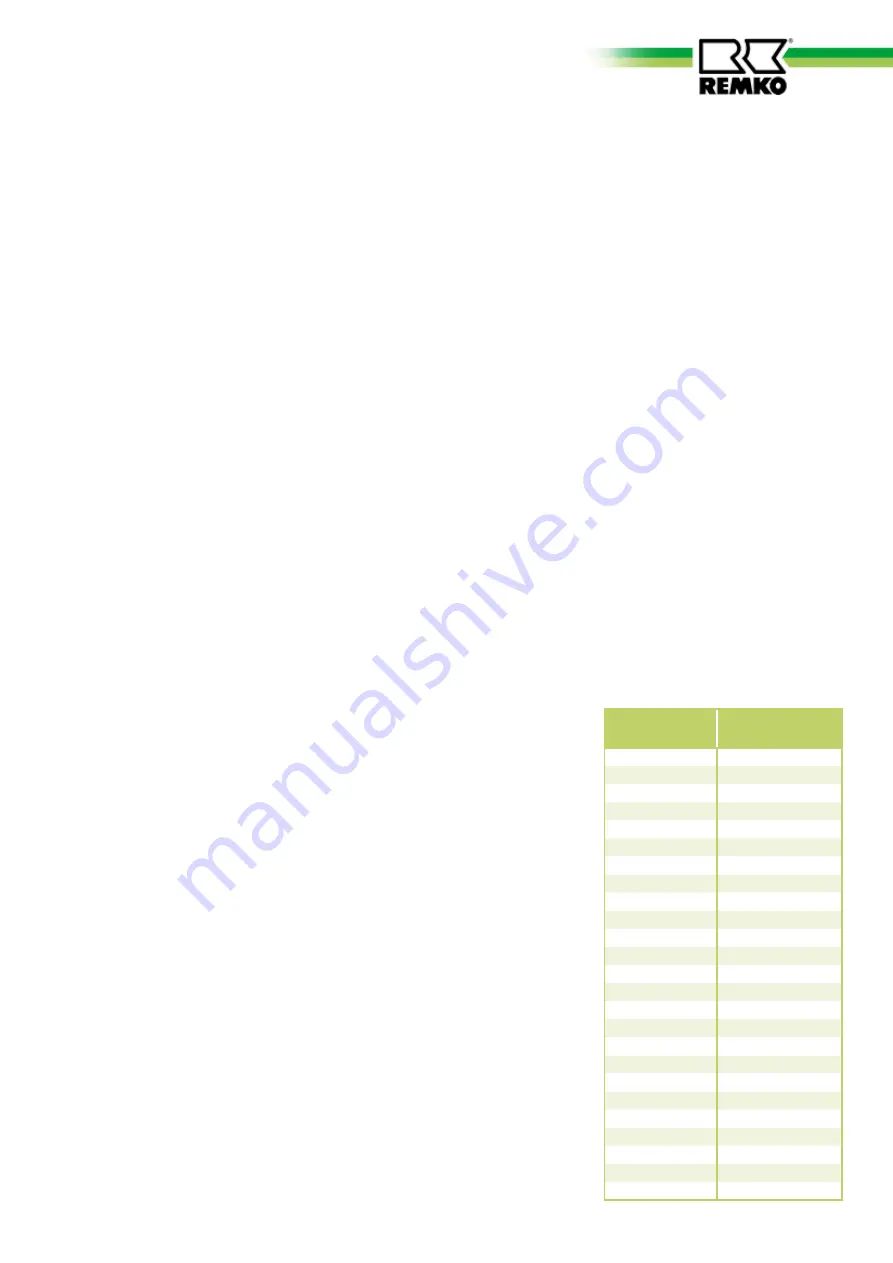

Measurement

temperature

C°

Probe resistance

value

NTC

-20

71.67 k

Ω

-15

55.99 k

Ω

-10

44.07 k

Ω

-5

34.92 k

Ω

0

27.86 k

Ω

+5

22.39 k

Ω

+10

18.13 k

Ω

+15

14.77 k

Ω

+20

12.11 k

Ω

+25

10.00 k

Ω

+30

8.29 k

Ω

+35

6.92 k

Ω

+40

5.80 k

Ω

+45

4.89 k

Ω

+50

4.14 k

Ω

+55

3.52 k

Ω

+60

3.01 k

Ω

+65

2.58 k

Ω

+70

2.22 k

Ω

+75

1.92 k

Ω

+80

1.66 k

Ω

+85

1.45 k

Ω

+90

1.26 k

Ω

+95

1.11 k

Ω

+100

0.98 k

Ω

Flow switch FL

The flow monitor measures an

adequately large flow of the me-

dium and switches off the unit if the

minimum flow volume is to low or if

the flow volume is too high.

Thermal contacts

Condenser fans TX1 / TX2

The condenser fan's thermal con-

tacts prevent overheating of the

motors.

Motor overload switch

compressor FL

The protection switch limits the

compressor's operating current.

Temperature controller TS for

heater TR

The controller regulates the heater

to ensure continuous condensate

draining at low ambient tempera-

tures.

Phase sequence relay FCR

(only RVS 100H / RVS 150H)

The phase sequence relay controls

the phase sequence of the power

supply. The relay will not be acti-

vated if the sequence is incorrect.

Fan speed control board A2

To keep noise level to minimum

the fans speed can be regulated by

adjusting the current.

The controller μC2SE calculates the

temperature in the condenser over

the TR 1 tranceducer.

The target value is then adjusted

over the fan speed controll board

A2.

Probe medium intake B 1

The probe is located at the unit’s

medium intake (system return). It

serves to monitor the medium tem-

perature to regulate the target value.

Probe medium output B 2

The probe is located at the unit’s

medium output (system supply).

It serves to monitor the medium

temperature and regulate the anti-

freeze protection temperature.

Probe Condenser B 3

The probe is located at the unit’s

condenser. It serves to monitor the

condenser’s temperature.

Reversing valve cooling cycle EV

The four-wax-reversing valve

makes the switching of the cooling

cycle possible to change from cool-

ing mode to heating mode.

Pressure transducer cooling cycle

TR 1

The trancuducer is located in

the cooling cycle’s heat gas side.

It serves to monitor the current

condenser pressure and regulate

the fan over the central fan speed

control board.

29

Summary of Contents for RVS 100H INOX

Page 2: ......