Troubleshooting

NOTE

If no result is achieved after

carrying out all functional

checks, an authorised service

station should be contacted.

ATTENTION

Prior to carrying out mainte-

nance or repairs, the unit must

always be disconnected from

the supply.

Fault

Possible cause

Remedy

• The unit does not start.

• Lightning symbol in display does

not light.

No supply voltage.

• Check supply connection and local

fuses or switches.

• The unit does not start.

• The lightning symbol shows

constant „green“.

Room humidity too low.

The unit is outside its operating

limits of 10 – 36°C.

• Check the integrated or external

hygrostat by setting it to a low

relative humidity, e.g. < 40%.

If the unit does not switch on

again, the integrated or external

hygrostat must be checked for a

fault.

• Check the room conditions and

change if necessary.

• The compressor does not start.

• The triangle symbol in the dis-

play flashes constant „red“.

The compressor was automati-

cally switched off due to exces-

sive temperature.

Lack of ventilation.

Excessive ambient temperature.

Clogged filter/suction.

If the unit does not start after 45

minutes, the following must be

checked:

• Check that the fan/fans is/are

operating.

• Check whether the suction filter is

clogged.

• Check that the suction and blow

out openings are free.

• Check whether the condenser gills

are fouled

• Check whether the room

temperature is possibly above 36°C.

If the room temperature is above

36°C, the unit must be switched

off.

• The lightning symbol in the

display shows constant „green“.

• The drop symbol in the display

flashes constant „green“.

Indicates that the unit is operat-

ing, but has switched off due to

overheating.

• The indication can be cancelled by

disconnecting and reconnecting the

supply.

ATTENTION

Only an authorised specialised

company may carry out work

on the refrigeration system and

electrical equipment!

12

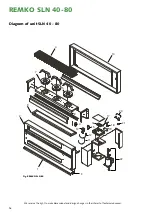

REMKO SLN 40-80