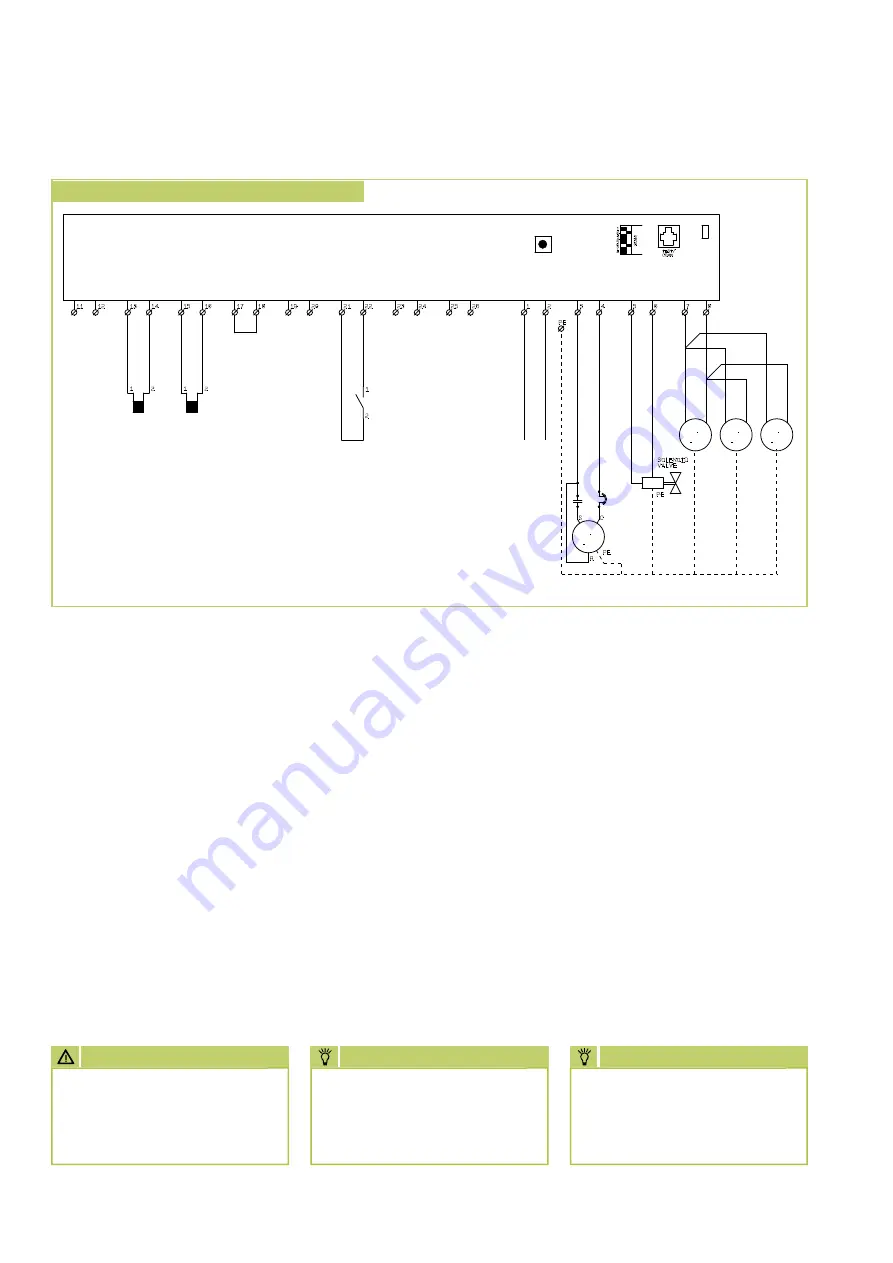

Legend:

HYG = Hygrostat

M 1 = Compressor

M 2 = Fan motor 1

M 3 = Fan motor 2

M 4 = Fan motor 3

Y 1 = Solenoid valve

R3.1 = Condenser sensor

R3.2 = Evaporator sensor

Electrical wiring diagram

R3.1

R3.2

HYG

L1 N

230V

50 Hz

M 1

M

1~

M

1~

M 2

Y 1

Test

M

1~

M

1~

M 4

M 3

AMB.

NTC

COND.

NTC

EVAP.

NTC

PRES.

THA

WAT.

SENS

HYG

TH.

STAT

FAN

MAINS

FAN

COMPR.

VALVE

HEAT

Fan motors:

SLN 40 = Motor M2

SLN 60 = Motor M2 and M3

SLN 80 = Motor M2 M3 and M4

Constant ventilation:

If constant air circulation is re-

quired, i.e. independent of de-

humidification, a jumper can be

connected between terminals

25

and 26

.

The fan or fans then operate with-

out any control and monitoring in

a continuous mode.

External hygrostat:

Recommended for frequent hu-

midity variation is the installation

of an external hygrostat which is

available as an accessory.

Disconnect the integrated hygro-

stat at terminals

21 and 22

.

Install the external hygrostat at a

suitable location in the room to

be dehumidified and connect to

terminals

21 and 22

.

The output voltage on terminals

21 and 22

is

12V

.

NOTE

Only authorised specialists

may install and carry out

maintenance work on the

units!

Electronic control board

NOTE

A disconnector switch should

be installed in the supply con-

nection at a suitable and easily

accessible location.

ATTENTION

Prior to carrying out mainte-

nance or repairs, the unit must

always be disconnected from

the supply.

We reserve the right to make dimensional and design changes in the interest of technical advances.

SLN 40 - SLN 80

14

REMKO SLN 40-80