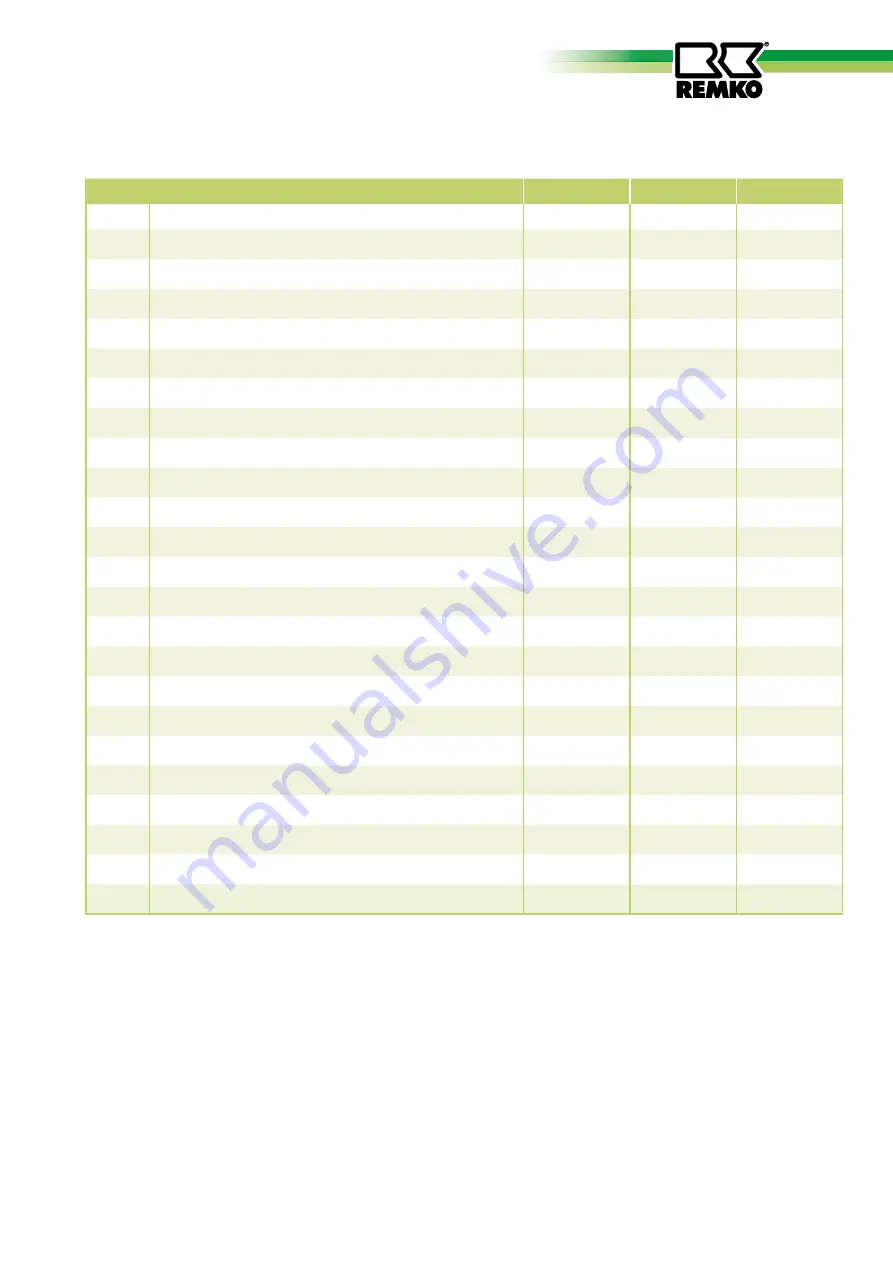

When ordering spare parts, please always also quote the serial number (see (see rating plate)!

Spare parts list

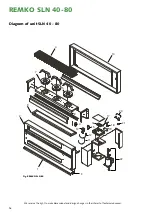

No.

Designation

SLN 40

SLN 60

SLN 80

EDP No.

EDP No.

EDP No.

1

Wall bracket

1109144

1109165

1109177

2

Housing rear

1109188

1109189

1109190

3

Cable gland

1109129

1109129

1109129

4

Condenser

1109146

1109167

1109179

5

Fan complete with 80mm cable

1109147

1109147

1109147

6

Fan complete with 1200mm cable

— —

1109168

1109168

7

Fan complete with 1600mm cable

— —

— —

1109180

8

Evaporator

1109148

1109169

1109181

9

Condensate tray, complete

1109149

1109170

1109182

10

Front panel

1109194

1109195

1109196

11

Evaporator sensor (metal)

1109160

1109160

1109111

12

Condenser sensor

1109161

1109161

1109161

13

Thermo valve

1109158

1109173

1109185

14

Hygrostat

1109115

1109115

1109115

15

Dry filter

1109157

1109157

1109157

16

Control board

1109152

1109152

1109152

17

Diode board with cable

1109154

1109154

1109154

18

Terminal, two-pole

1109155

1109155

1109155

19

Capacitor

1109156

1109156

1109156

20

Solenoid valve, complete

1109110

1109110

1109110

21

Non-return valve

— —

1109176

1109176

22

Compressor, complete

1109162

1109174

1109186

-

Recirculation suction filter

1109191

1109192

1109193

17