Installation

For optimal and reliable unit op-

eration, the following information

must be observed in any event:

■

Prior to installation of the units

in an adjacent room, two duct

openings must be provided in

the wall/brickwork between the

room to be dehumidified and

the installation room.

The sizes of these openings are

shown in the diagram.

■

The openings must be made in

such a way that the air in the

room to be dehumidified is able

to be sucked in unhindered

through the lower duct (with

filter) and blown out through

the upper duct.

■

For reliable operation, the speci-

fied minimum clearances from

the unit to the ceiling and to

the floor in the installation room

must be taken into account.

■

The recirculation suction filter,

grille connections and air inlet

grille must be fitted together

with the wall connection.

■

The two duct connections must

be installed in the duct open-

ings.

■

Prior to joining the duct connec-

tions, the wall connections must

be adapted to the necessary

lengths.

The maximum wall thickness is

limited to 240mm.

■

The duct section with filter in

the lower duct opening where

the air of the room to be dehu-

midified is sucked into the unit

must be fitted.

■

The unit connection with self-

sealing profile lips must be con-

nected to the duct connection

located in the wall opening from

the adjacent room side.

■

The supplied wall bracket must

be fixed to the wall in the adja-

cent room and the unit mount-

ed on the same.

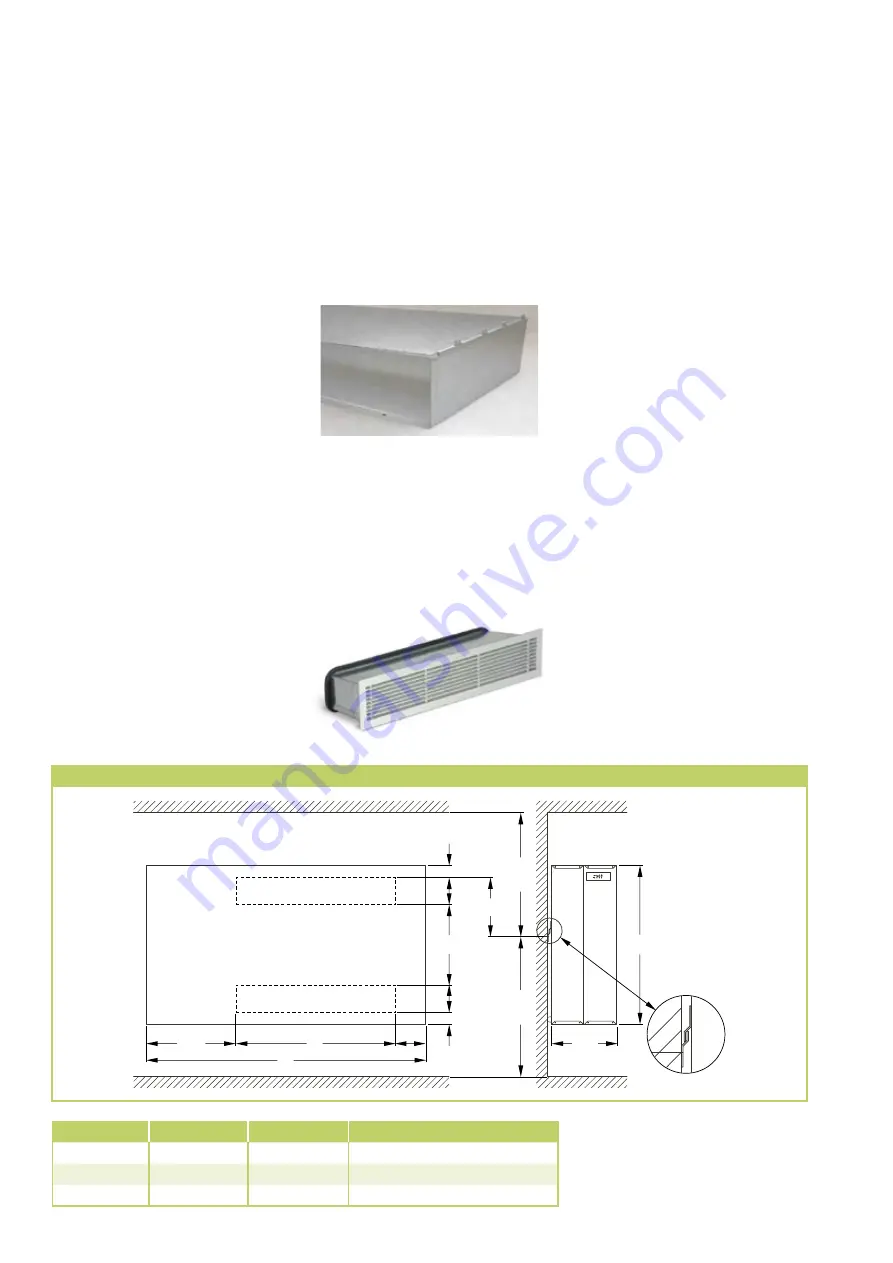

Series

Dimension A Dimension B

Wall opening

SLN 40

387

887

130 x 410

SLN 60

692

1192

130 x 720

SLN 80

1232

1732

130 x 1260

All dimensions in mm

Wall mounting of units

51

51

116

116

343

min.

530

min.

600

250

677

384

A

B

116

280

8

REMKO SLN 40-80