Positioning condensate drain

105

318

Condensate drain

The condensate drain is located at

the bottom of the unit.

The condensate drain must be

connected to the supplied drain

connection.

A solid or flexible ½“ drain con-

nection can be connected.

■

The drain hose must always be

installed with a minimum gradi-

ent of 2% to enable the water

to drain unhindered from the

drip tray.

■

Alternatively, a condensate

pump (accessory) can also be

mounted on the unit in order to

pump the produced condensate

to a raised outlet.

■

For an outlet through the wall,

specific preparations are neces-

sary for correct condensate

drainage prior to installation

of the unit, e.g. the drilling of

holes.

■

The position of the outlet con-

nection is shown in the diagram

below.

Access to control

Remove the front plate after

removing the Allen screws. Lift up

the cover and remove from the

unit horizontally.

The control is located in a housing

above the compressor.

Access to the control takes place

by removing the 4 screws on the

sides of the housing.

■

Connection to the duct connec-

tion already installed in the wall

takes place with the self-sealing

profile lips located on the unit

connection.

■

The unit must be mounted or

installed horizontally to ensure

unhindered condensate drain-

age.

■

The unit should not be installed

close to radiators or other heat

sources.

■

The room to be dehumidified

must be closed from the ambi-

ent atmosphere.

■

Open windows, doors, etc., as

well as frequent entering and

leaving the room should be

avoided as far as possible.

■

For optimal room air circulation

by the dehumidifier, the supply

and exhaust air openings must

always be kept free of dirt and

other obstacles.

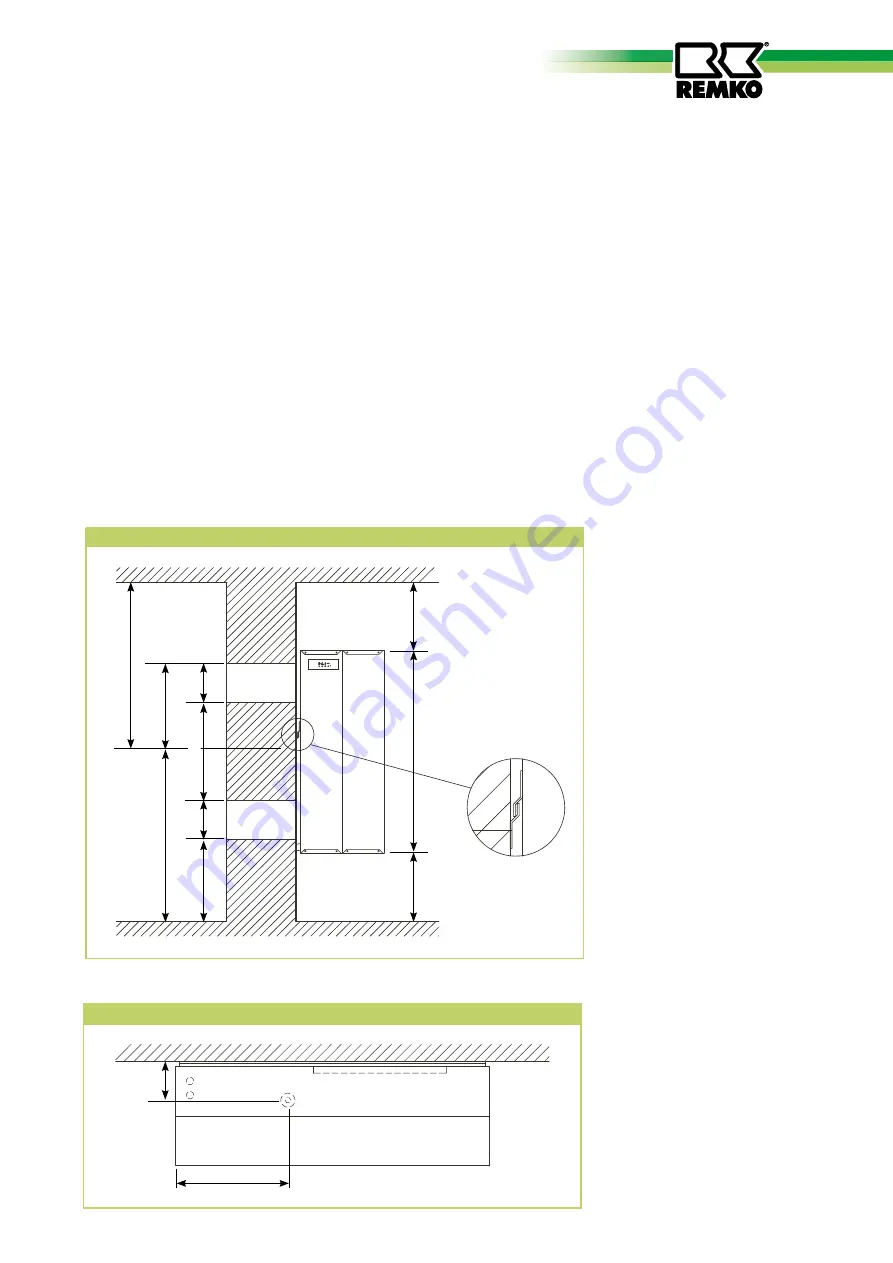

All dimensions in mm

All dimensions in mm

Min. 530

Min. 225

677

Min. 225

130

268

130

600

257

Positioning wall bracket taking the SLN 60 as an example

329

9