Assembly Instruction

If you suspect you may have some parts missing, please

contact us before going back to your retailer. Refer to the

Customer Support section on page 4 for contact details.

!

This Air Mag. M.W. II takes up

a floor space of 110cm x 60cm for use,

and weighs 46.5kg

!

Before you start

1.

Prepare your work area -

It is important for you to

assemble the product at

a clean and uncluttered

space.

2.

Work with a friend -

we recommend you to

have someone assisting

you with the assembly as

some of the components

are quite heavy.

3.

Open the carton -

checking any warnings

on the carton and make

sure you have it the right

way up.

4.

Unpack the carton

Make sure you have

the following parts:

Tools and Consumables

5

Allen Key (8mm, 6mm and 5mm)

Part

No.

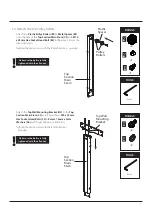

G1

Bottom Section

Main Stem

x 1

Part

No.

C2

Top Wall Mounting

Bracket

x 1

Part

No.

H2

Top Section

Main Stem

x 1

Fixings

Part

No.

S3

M8 x 30mm

Hex Socket

Head Bolt

x 2

Part

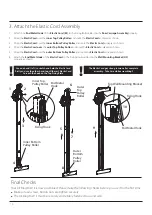

No.

B1

Elastic Cord

x 2

Part

No.

H1

Bottom Wall

Mounting

Bracket

x 1

Part

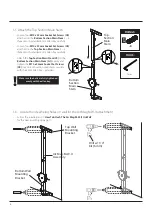

No.

A28

Left Lock Handle

- 92mm

x 1

Part

No.

S4

M10 x 20mm

Hex Socket

Head Bolt

x 3

Part

No.

S6

8 x 16 x 2mm

Washer

x 2

Part

No.

B2

Plastic Pulley

Roller

x 4

Part

No.

B3

M10 x 40mm

Hex Socket

Head Bolt

x 2

Part

No.

B4

Metal Spacer

x 2

Part

No.

S5

10 x 18 x 2mm

Washer

x 3

Wrench (13/17mm )

5/16” Hex Head Lag Screw

x 8

5/16” Washer

x 8

Part

No.

W1

Part

No.

W2

Part

No.

A3

Right Lock Handle

- 128mm

x 1

Part

No.

S7

M8 x 25mm

Hex Socket

Head Bolt

x 4