RX72M Group

Single-Chip Motor Control via EtherCAT Communications

R01AN5434EJ0110 Rev.1.10

Page 25 of 85

Aug.31.2020

4. Motion Control Parameters

The definitions of the settings in the sample program for the motion control parameters set in the CiA402

objects are given below.

4.1 Velocity Parameters

In the sample program, the parameter serving as the unit of velocity is defined as the number counted from

the encoder per control cycle. Since the control cycle is very short, the velocity values are handled as fixed-

point numbers in 16.16 bit format after being multiplied by 2

16

, i.e. 65536.

For the conversion of the unit of velocity produced by counting from the encoder per second to the

corresponding control parameter, the number has to be multiplied by the number of control cycle time slices

in a second and then by 65536.

Since the control cycle of the sample program is 500 us, the velocity derived from 5000 being counted by the

encoder in a second is converted by the formula:

5000 × 0.0005 × 65536 = 163840

So, the corresponding velocity value is 163840.

4.2 Acceleration Parameters

In the sample program, the unit of acceleration parameter is defined as the number counted by the encoder

per square of the control cycle. In a similar way to the calculation and handling of velocity, the acceleration

and deceleration values are handled as fixed-point numbers in 16.16 bit format after being multiplied by 2

16

,

i.e. 65536.

For the conversion of unit from the number counted by the encoder count per second to the control

parameter, the number has to be multiplied by the square of the position cycle time slice and then by 65536.

Since the control cycle is 500 us, the acceleration derived from 5000 being counted by the encoder in a

second is converted by the formula:

5000 × 0.0005 × 0.0005 × 65536 = 81

So, the corresponding acceleration value is 81.

4.3

Conversion of Units by the RMW

The control parameters such as gain obtained through tuning by the motor control development support tool

"Renesas Motor Workbench" are reflected in the source code of the motor control program, so the same

values are also used in control via EtherCAT.

On the other hand, as the position and velocity command values that the RMW uses are in different units

from those specified for use as motion control parameters set in the CiA402 objects, conversion is required.

Table 4-1 lists the formulae used to convert command values used in the RMW into CiA402 object command

values.

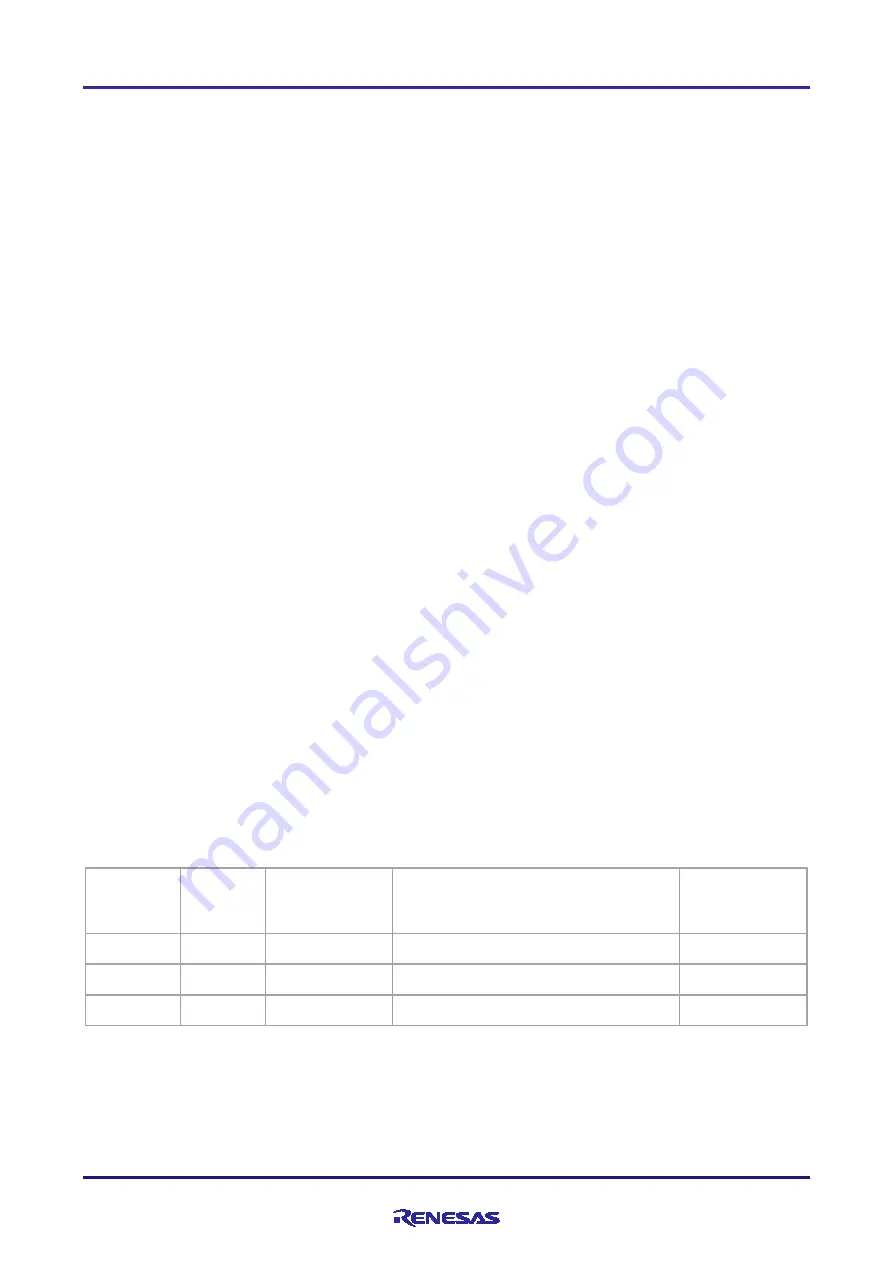

Table 4-1 Command Value Conversion Formulae: RMW to CiA402

Item

RMW

Command

Value

CiA402

Command Value

Formulae

Data Type

Position

Θ[deg]

P

C

[count]

P

C

=

Θ

÷ 360 × CPR

INT32

Velocity

R[rpm]

S

C

[count/s]

SC = R ÷ 60 × CPR × T

S

× K

Q

INT32 (16.16)

Acceleration t

ACC

[s] *

1

A

C

[count/s

2

]

AC = R ÷ t

ACC

÷ 60 × CPR × T

S

× T

S

× K

Q

UINT32 (16.16)