1.800.627.4499

32

Integral Indirect Gas-Fired Heat Module

OPTION

5.7 INSTALL SUPPLY AIR TEMPERATURE SENSOR

The Supply Air temperature sensor is factory-wired to the Integrated Programmable Controller

but the sensor must be installed in the SA ductwork downstream of the gas heat module. The

temperature sensor should be installed between 4 and 6 feet from the unit in the SA ductwork

to control the temperature output of the gas heat module.

The Supply Air temperature sensor is shipped in the low-voltage side of the unit electrical box.

5.8 INSTALL GAS SUPPLY PIPING

5.8.1 Installation of Gas Piping

All components of this or any other gas-fired heating unit must be leak-tested prior to plac-

ing the unit into operation. A soap and water solution or other non-corrosive leak detection

fluid should be used to perform this test. NEVER test for gas leaks with an open flame.

WARNING

When leak testing at pressures equal to or less than 14 inches WC [3.5 kPa], first close the

field-installed shutoff valve to isolate the unit from the gas supply.

WARNING

INSTALLATION

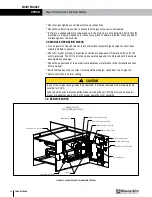

5.6 MODULE INSTALLATION REQUIREMENTS

The heat module is installed on the positive pressure side of the ERV air blower. The air

throughput must be within the CFM range marked on the module rating plate.

Ductwork should be mechanically fastened to the unit. Joints should be sealed with high

temperature silicone caulking or high temperature tape to prevent leakage of circulating air. All

outdoor module duct connections must be weathertight to prevent rain and snow from entering

the ductwork. Support all ductwork securely. DO NOT rely solely on module duct connections

for support. Provide removable access panels in ductwork immediately downstream of the heat

module to allow for inspection of the heat exchanger. These openings should be large enough to

observe smoke or reflected light inside the casing to inspect the heat exchanger for leaks and to

check for hot spots on the heat exchanger due to poor air distribution or insufficient air volume.

Attach covers so as to prevent air leakage. See figure below.

FIGURE 5.6.0 INSTALLATION EXAMPLE

TITLE:

DESCRIPTION OF REVISION

63 MICROINCH MINIMUM

DATE:

RenewAire LLC

SCALE:1:30

SIZE

DWG. NO.

DATE

-

-

-

BY

MATERIAL:

SURFACE FINISH =

SHEET 1 OF 1

DO NOT SCALE DRAWING.

DATE:

-

LEVEL

TOLL FREE: (800) 627-4499

DN-3-IN GH INSTALLATION EXAMPLE

--

-

APPLICABLE STANDARDS: DIM.

CHECKED BY:

--

CAH

3

REMOVE ALL BURRS, BREAK

DRAWN BY:

SEE BILL OF MATERIAL

FINISH:

A

SHARP EDGES.

FEB19

AND TOL. ANSI Y14.5

10/29/18

DN IN GH Installation

UNLESS OTHERWISE SPECIFIED,

DIMENSIONS ARE IN INCHES.

TOLERANCES:

LINEAR 0.015

HOLE SIZE 0.005

ANGULARITY

4510 Helgesen Dr.

Madison, WI 53718 USA

TEL: (608) 221-4499

FAX: (608) 221-2824

SEE BILL OF MATERIAL

Roof Deck

Combustion Air

Intake Hood

Combustion Air

Flue Exhaust Vent

Access Panel

in SA Duct

Gas Heat Module

Condensate Drain Tube

Gas Pipe Connection

Supply Air

Duct

Outside Air

Duct

Return Air

Duct