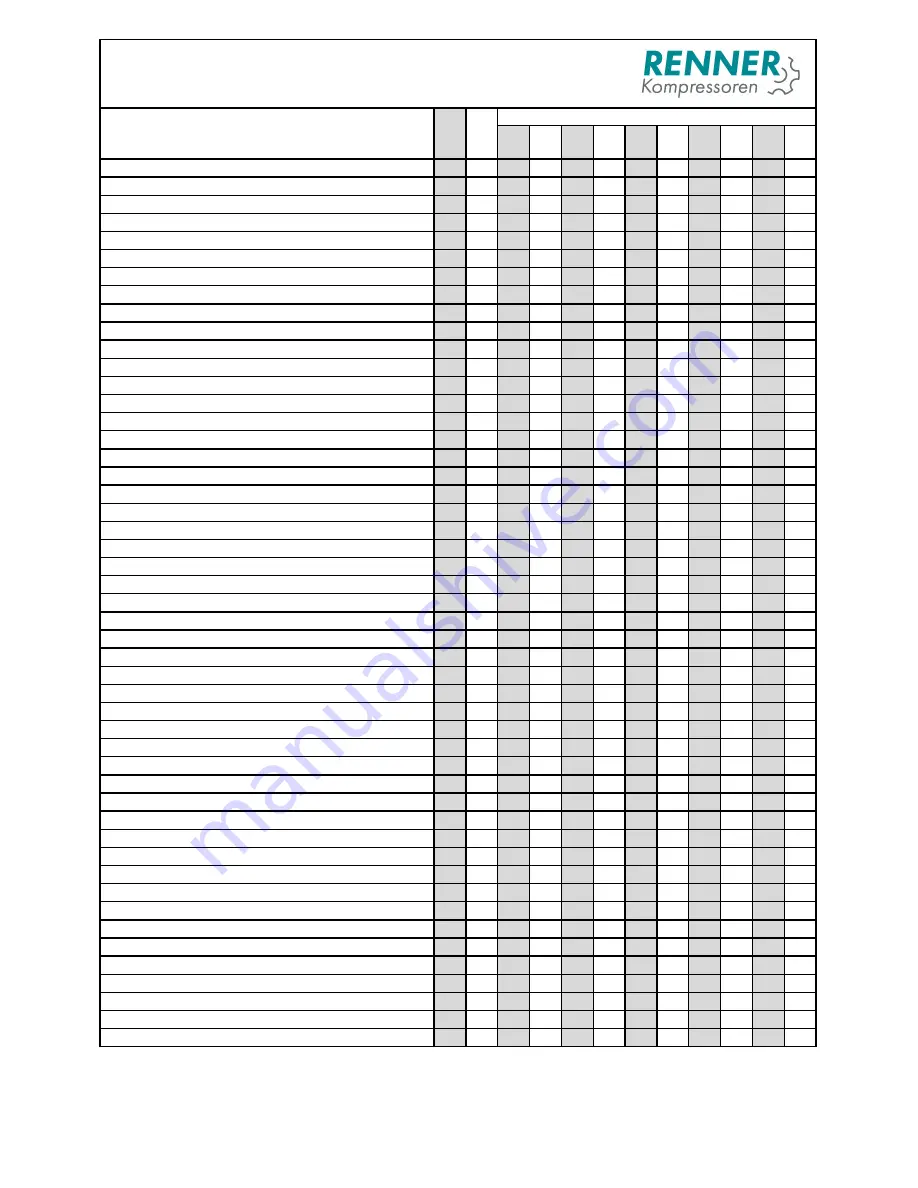

2000

4000

6000

8000

10000

12000

14000

16000

18000

20000

Fill out Commissioning report

Check screw connections and tighten if necessary

Check that all connections are firm and tight

Checking the oil Level

Check the V-belt tension and wear

Tighten electric clamps

Functional check of pressure and temperatur gauges

Measuring / testing current consumption

Check ON and OFF settings and adjust if necessary

Check the alignment of the V-belt pulleys

Check the dirt level of the air filter and the possibly mounted ventilator filter pads

Compressors with air receiver, empty the condensate water*

Examine all the hoses to ensure that they are in good working condition

Check funktion of the condensate drain*

Check contactors for wear

Control the oil / air cooler and clean if necessary

Check the compressor to ensure that it has no leaks

Check the overall condition of the compressor

Check air filter element, replace if necessary

Clean / replace the filter mats*

Check / replace the safety valve

Changing the oil filter

Change the oil

Change the fine separator cartridge

Check the follow-on time (>= 3 min)

Replace the O-ring on the oil filler plug

Change oil suction / recirculation hoses

Change control air hose

Maintenance set minimum pressure valve

Change the V-belt

Replace thermal valve element

Maintenance condensate drain*

Replace solenoid valve

Servicing kit for the intake regulator

Replace minimum pressure valve completely

Replace oil hoses*

Replace pressure switch / pressure sensor

Replace motor bearings A and B side

Replace electrical contactors

Maintenance package 1 (see maintenance package List for each compressor)

Maintenance package 2

Maintenance package 3

Maintenance package 4

Maintenance package 5

Maintenance package 6

Maintenance package 7

Maintenance package 8

Maintenance package 9

Maintenance package 10

* if existing

after ... hours

Appendix W - Maintenance Control

for RS-B 3 - 11

with more than 2000 hours / year

Maintenance work

co

m

m

is

si

o

n

in

g

p

er

io

d

i

ca

lly