3 - Installation and start-up

3 - 3

3.2 Connections

This section covers important instructions which you need to

observe in order to safely connect the compressor to the com-

pressed air system as well as the electrical supply.

Warning!

Before connecting the machine to the compressed air system,

all conduits and hose connections inside the compressor must

be checked

and, if necessary, retraced.

For plants with pressure tanks, an acceptance check of the air

collection tank must be made in the most countries by a com-

pressed air tank expert before commissioning.

Start an inspection log!

A Compressed air connection

The system has all the required conduits and is ready for opera-

tion.

The following must be observed when connecting to the com-

pressed air system:

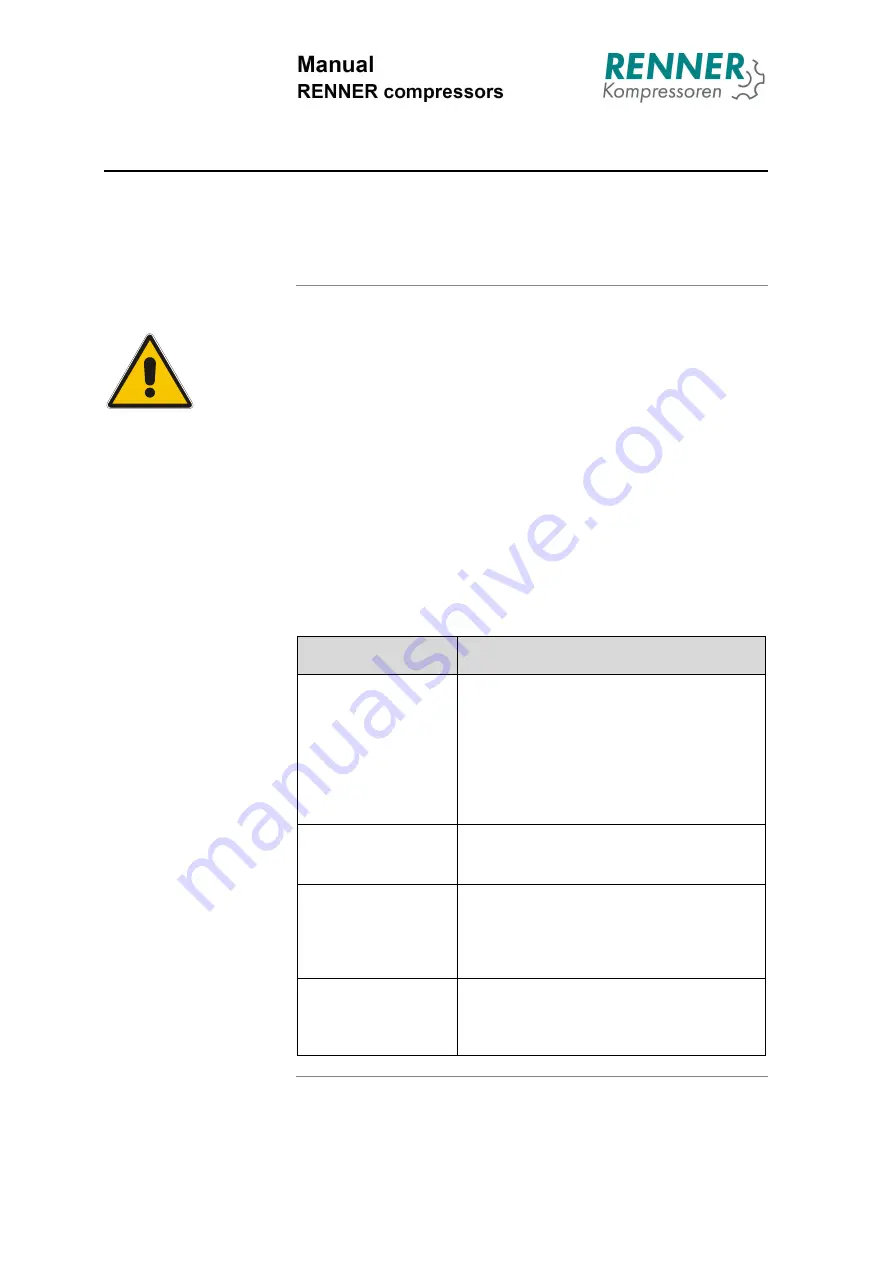

Key word

Ensure that

Pressure

•

Suitable screws and conduits are used for

the operating pressure

•

The final pressure of the system is not

higher than stated on the rating plate.

•

A non-return valve between the machine

and the compressed air system is not

required as it has already been integrated

in the machine.

Connection

•

Connect the machine to thecompressed

air system stress-free and free from vibra-

tion e.g. by using a flexible hose

Shut-off valve

•

The additional installation of a shut-off

valve is recommended to facilitate

maintenance tasks at the compressor

without de-pressurising the compressed

air system.

Condensate

•

An automatic condensate trap can be

integrated behind the after cooler for im-

proved condensate separation from the

compressed air

Contents

Compressed air

connection

Summary of Contents for Scroll Line Industry Series

Page 60: ...Appendix T Data sheets 015x765x1462 AT Appendix Data sheets AT...

Page 62: ......

Page 63: ......

Page 64: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 92: ...A ADS Appendix Pressure Switch AADS 2 Appendix ADS End Pressure Switch...