5 Maintenance

5 - 9

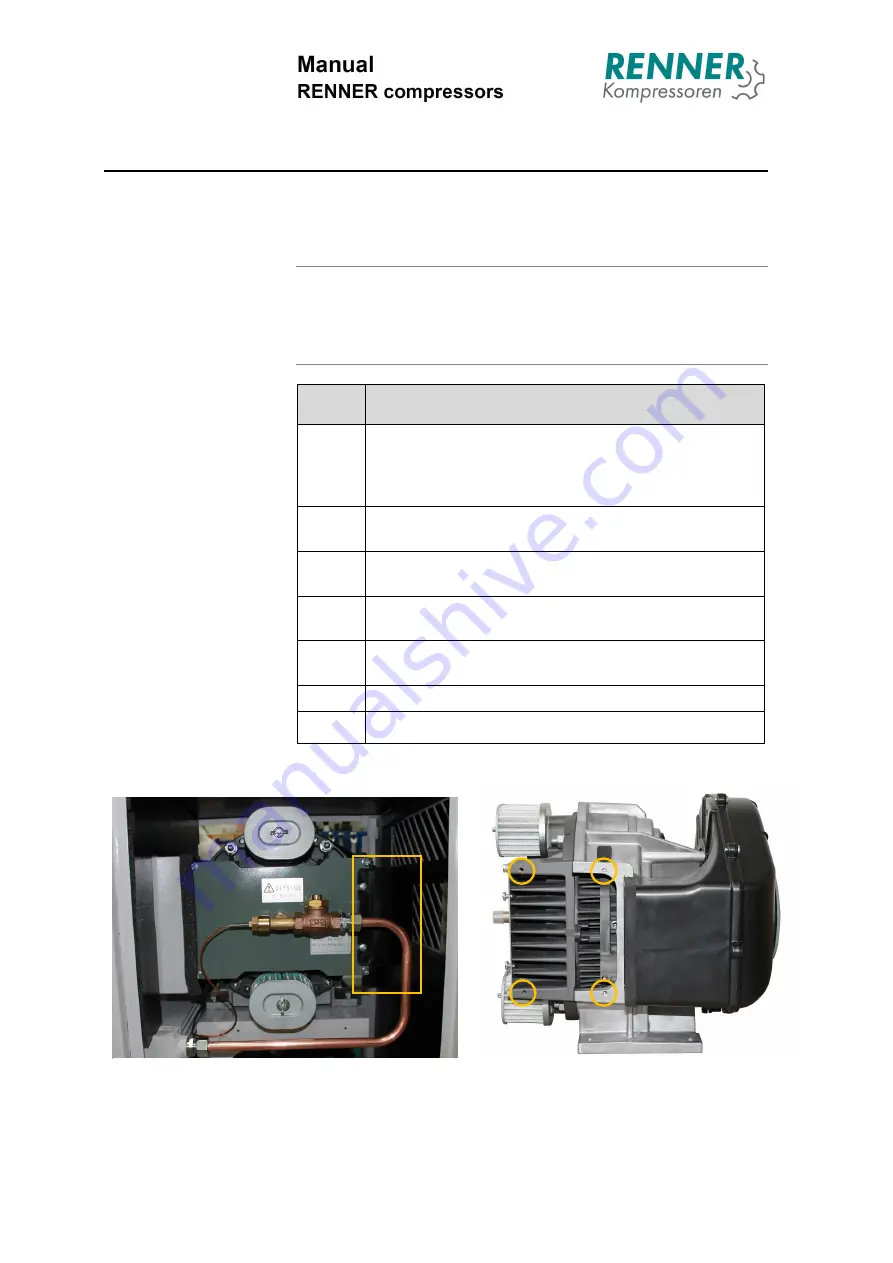

5.3.4 Cleaning the SCROLL cooling fins

This chapter provides information about cleaning the cooling

fins in the SCROLL compressor

The cooling fins of the SCROLL compressor are an integral part

of cooling the compressor and must be checked and cleaned

regularly. (see maintenance plan)

Step

Operation

1

Disconnect the compressor from power and com-

pressed air system.

Secure from unintentional restart. Allow the com-

pressor to sufficiently cool down.

2

Remove the copper pipe connection between the

compressor block (air end) and cooler

3

Loosen the screws (Fig. 2) of the cooler fin cover

and then remove the cover (Fig. 1).

4

Loosen the lateral cover of the cooling fins (Fig. 3)

from the compressor block.

5

Thereafter, carefully blow out the cooling fins (Fig. 4)

or clean with a cloth.

6

Complete assembly in reverse order.

7

Carry out a test run and a functional check.

Contents

General points

Cleaning the cooler

fins

Fig. 1 cooler fin cover

Fig. 2 screws cooler fin cover

Summary of Contents for Scroll Line Industry Series

Page 60: ...Appendix T Data sheets 015x765x1462 AT Appendix Data sheets AT...

Page 62: ......

Page 63: ......

Page 64: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 92: ...A ADS Appendix Pressure Switch AADS 2 Appendix ADS End Pressure Switch...