V8205, VR8205 DIRECT IGNITION COMBINATION GAS CONTROLS

69-0329—05

4

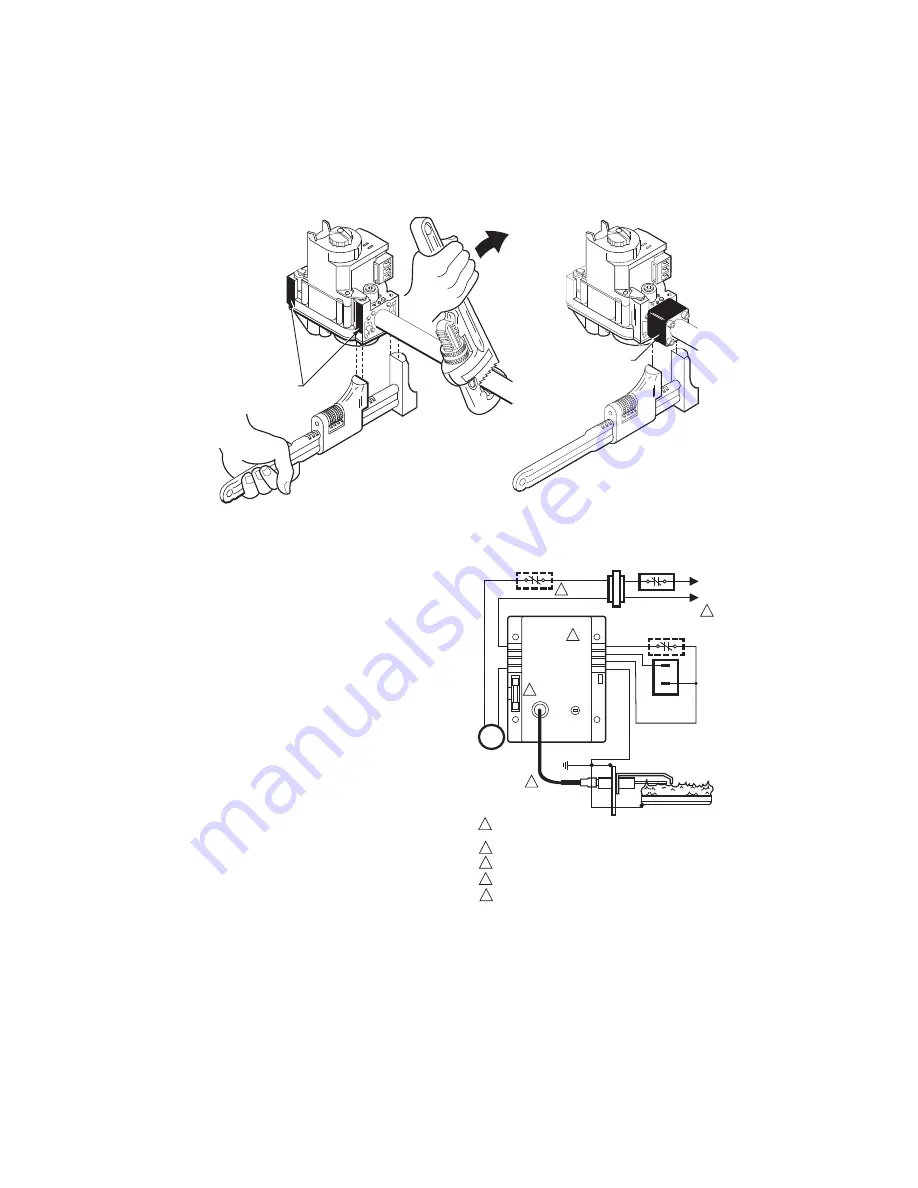

Fig. 5. Proper use of wrench on gas control with and without flanges.

WIRING

Follow the wiring instructions furnished by the appliance

manufacturer, if available, or use the general instructions

provided below. Where these instructions differ from the

appliance manufacturer, follow the appliance

manufacturer’s instructions.

All wiring must comply with applicable electrical codes

and ordinances.

Disconnect power supply before making wiring

connections to prevent electrical shock or equipment

damage.

1.

Check the power supply rating on the gas control

and make sure it matches the available supply.

Install the trans-former, thermostat, and other con-

trols as required.

2.

Connect control circuit to gas control terminals.

3.

Adjust thermostat heat anticipator to 0.50A rating

stamped on valve operator.

NOTE:

Use leadwires with insulated terminals.

Fig. 6. Wiring connections for 24 volt control in S87

direct ignition system.

APPLY WRENCH

FROM TOP OR

BOTTOM OF GAS

CONTROL TO

EITHER SHADED AREA

WHEN FLANGE IS NOT USED

APPLY WRENCH

TO FLANGE ONLY

WHEN FLANGE IS USED

M3084A

24V

24V (GND)

S87B CONTROL MODULE

ALARM

VALVE

VALVE

GND

TEMPERATURE

CONTROLLER

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

ALTERNATE LIMIT CONTROLLER LOCATION.

MAXIMUM IGNITER-SENSOR CABLE LENGTH: 3 ft. (0.9 m) OR LESS.

3A REPLACEABLE FUSE.

ALARM TERMINAL PROVIDED ON SOME MODELS.

M9043A

MV

MV

L1

(HOT)

L2

1

2

1

2

3

DUAL VALVE

COMBINATION

GAS CONTROL

Q347 IGNITER-SENSOR

BURNER

4

4

5

IGNITER-SENSOR AND

BURNER GROUND

3

5

ALARM, IF USED