en

3

FlowSol

®

B HE

WMZ

1

Overview

• With integrated heat quantity measure-

ment via VFS Grundfos Direct Sensor

TM

• Pre-assembled twin-line pump station

• Integrated

DeltaSol

®

BX W controller

• Design insulation casing

• Innovative hinged controller panel for quick

and easy access to the hydraulic components

• Safety assembly with connection for the

diaphragm-type expansion vessel, safety valve

and pressure gauge

• Fill and drain valves

• Wall mounting bracket with mounting material

• Air separator with manual air vent for the

solar thermal system

Technical data

Circulating pump:

Wilo PARA ST15-130/7-50/ iPWM2-12

(power consumption of the pump: 25 W)

Safety valve: 6 bar

Pressure gauge: 0 ... 10 bar

Grundfos Direct Sensor™: VFS 1-12 / VFS 2-40

Non-return valves:

Opening pressure 20 mbar, openable

Connection to diaphragm-type expansion vessel:

¾'' ET, flat sealing

Outlet safety valve: ¾'' IT

Connections to the solar pipes:

¾" IT, at VFS: ¾" ET

Maximum temperature flow / return: 120 °C / 95 °C

Maximum pressure: 6 bar

Medium: Water with max. 50 % glycol

Dimensions:

Approx. 481 × 320 × 190 mm (with insulation)

Distance centres: 100 mm

Distance centre / wall: 67 mm

Material: Fittings: brass

Seals: AFM 34

Insulation: EPP foam

Note:

This pump station can be used with the heat

transfer fluids Tyfocor L, L eco and LS.

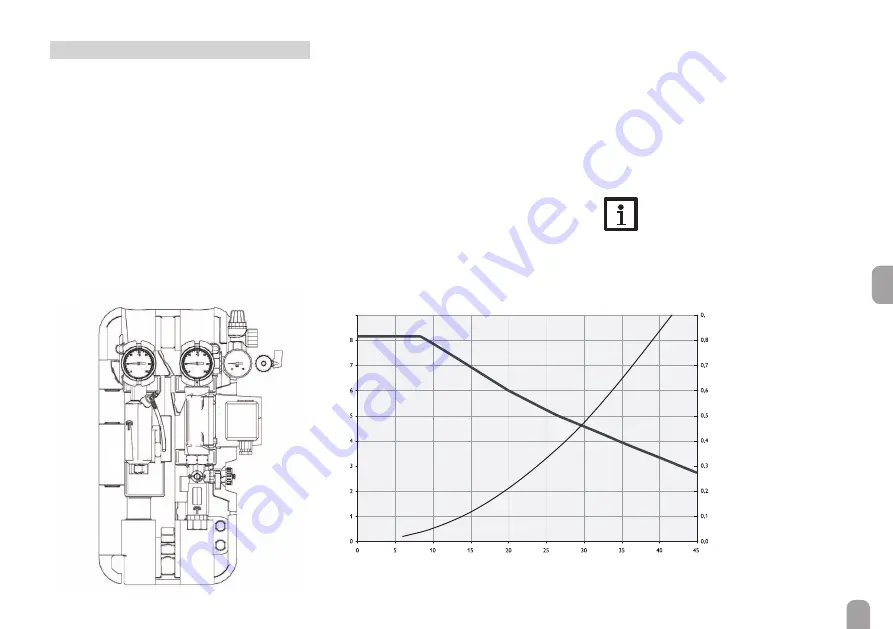

Pump characteristic / pressure loss characteristic

9

9

Wilo PARA ST15-130/7-50/ iPWM2-12

max.

Deliv

er

y height (m)

Flow rate (l/min)

Pr

essur

e loss (bar)