17

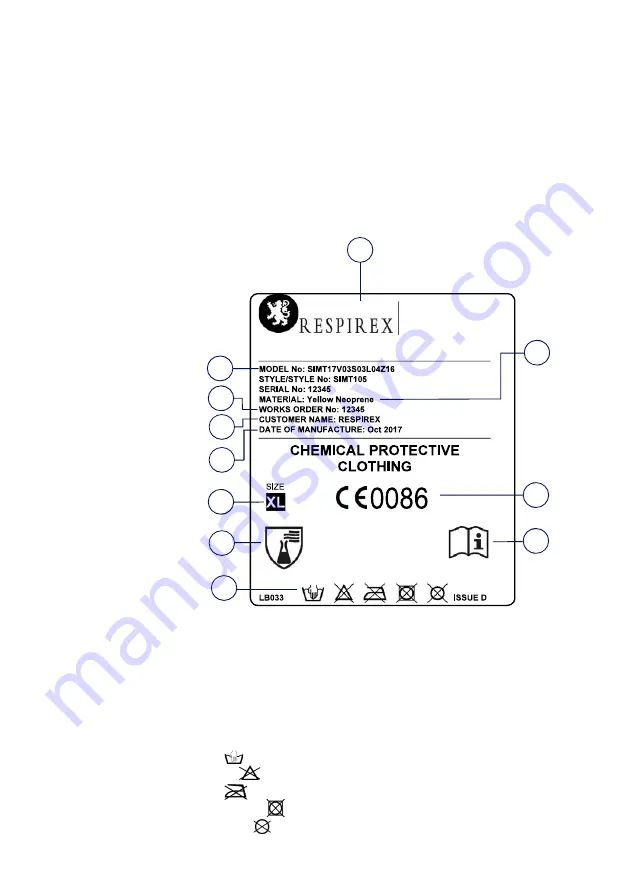

Product labelling

1.

Manufacturer of garment and address: Respirex International Ltd.

2.

Manufacturer’s Model number

3.

Material of Manufacture.

4.

Manufacturer’s Order No.

5.

Customer Name.

6.

Date of manufacture: Day/Month/Year.

7.

Garment Size

Size

Chest (cms)

S 88-96

M 96-104

L 104-112

XL 112-124

Product labelling

1.

Manufacturer of garment and address:

Respirex International Ltd.

2.

Manufacturer’s Model number

3.

Material of Manufacture.

4.

Manufacturer’s Order No.

5.

Customer Name.

6.

Date of manufacture: Day/Month/Year.

7.

Garment Size

Size

Chest (cms)

S

88-96

M

96-104

L

104-112

XL

112-124

XXL

124-136

UNIT F, KINGSFIELD BUSINESS CENTRE, PHILANTHROPIC ROAD,

REDHILL, SURREY, RH1 4DP. UNITED KINGDOM

info@respirex.co.uk

TEL +44 (0)1737 778600

FAX +44 (0)1737 779441

COMPLIES WITH A TECHNICAL SPECIFICATION

TO SATISFY ANNEX II OF THE PPE REGULATION

(EU) 2016/425

8.

CE Mark and notifi ed Body code.

9.

“Open Book Pictogram”; wearer must refer to the “Instructions for use” for further information.

10. Protection against liquid chemicals

11. Protection against electrostatic hazard

12. Protection against biological hazard

13. Five care pictograms indicating that clothing is not suitable for cleaning and reuse.

•

Pictogram 1 Hand wash

•

Pictogram 2 Do not bleach

•

Pictogram 3 Do not iron

•

Pictogram 4 Do not machine dry

•

Pictogram 5 Do not dry clean

11

7

10

1

9

6

8

3

5

4

2

19

8.

CE Mark and noticed Body code.

9.

“Open Book Pictogram”; wearer must refer to the“Instructions for use” for further information.

10. Protection against liquid chemicals

11. Protection against electrostatic hazard

12. Protection against biological hazard

13. Five care pictograms indicating that clothing is not suitable for cleaning and reuse.

•

Pictogram 1 Hand wash

•

Pictogram 2 Do not bleach

•

Pictogram 3 Do not iron

•

Pictogram 4 Do not machine dry

•

Pictogram 5 Do not dry clean