4

4.

The suit is free from contamination both inside and out.

5.

The identification number is clearly legible in the suit.

6.

The zip operates correctly and the pull tag(s) is in good condition.

7.

The suit materials are free from tears and holes, including the head of the garment. Pay particular

attention to the seam areas

8.

Ensure that the waist belt air attachment is secure and not damaged.

9.

A clean silencer is fitted.

10. The vision from the visor is not obstructed by large scratches and heavy scuff marks. On suits fitted with

rigid visors a removable outer visor can be fitted which prevents damage to the main visor. This can be

changed by simply peeling away from the Velcro fasteners and replaced with a new outer visor.

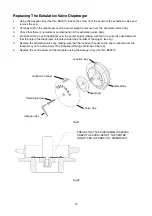

11. Respirex recommend that the exhalation valves are part of the visual precheck. If the valve diaphragm is

distorted or damaged in any way it must be replaced (see page 13).

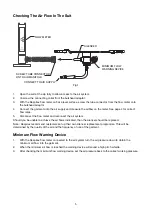

Inspection of the compressed air supply tube (medium pressure connecting hose) which supplies breathing

quality air to the operator must be carried out at least once per month and before each shift cycle and the

results recorded.

During the inspection the following should be checked:

1.

Lines are clean externally.

2.

Lines are free from damage (holes, splits, etc).

3.

Air line coupling connections are in good condition and the non-return valves are in good working order.

Submerge in water to locate any leaks if any sign of external damage is evident.

Report any defects to the supervisor and record them. The compressed air supply tube must NOT be used

until the defect has been rectified.

Maximum Length And Bore Of Medium Pressure Connecting Hose

Respirex recommend a minimum of 3/8” internal diameter bore hose is used approved to EN 270:1994. If other

Medium Pressure Hose and couplings are to be used they should be suitable for the intended use and conform

to the requirements of EN 270:1994 (a sample must be supplied to Respirex to enable the correct air settings

to be achieved).

The garment will be set by Respirex to give the correct rate of airflow to coincide with the customer’s supplied

airline pressure, as notified to Respirex and indicated on the airline waist belt label. The user shall assure

himself that the pressure range of the air supply to the apparatus is within the limits recommended by Respirex.

Maximum And Minimum Flow In Litres/minute

The airflow to the suit must be within the range:

Maximum 440 L/Min

Minimum 360 L/Min

This must be checked prior to each use by means of the Respirex airflow meter. (See page 5).