161

Intera 5.3

Overshoot - The overshoot is calculated as the difference in position of the end-effector measured

at the E-Stop time and the steady state time.

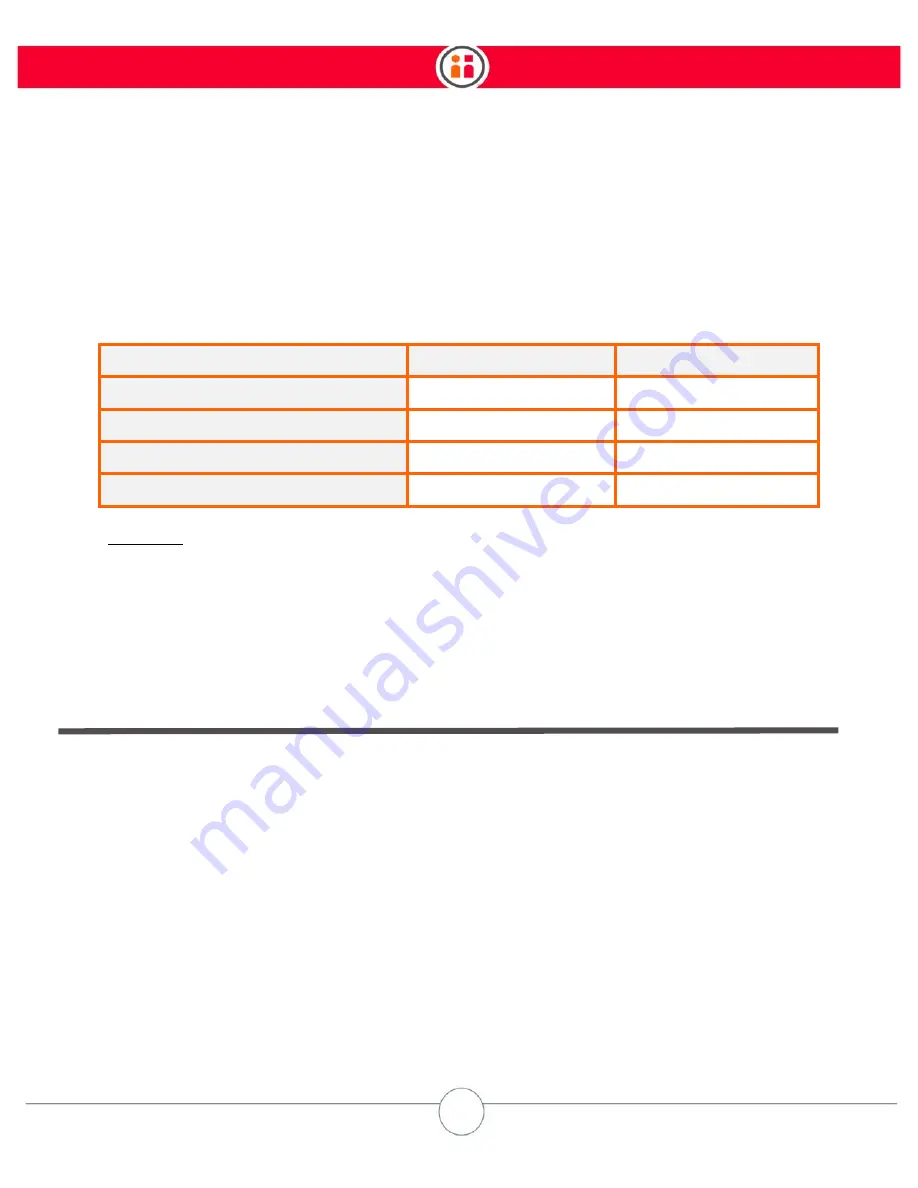

We also tested under multiple scenarios, and varied payload and voltage mode. The table below

summarizes the data from these runs.

Table D-1: E-Stop performance data for eight different conditions, varying the velocity mode and

the payload. The joint acceleration setting is set to

express

and the speed ratio is set to 1.0 in the

Intera software.

More information about low velocity mode can be found in the document titled

Sawyer Safety Over-

view: Low Power Mode

.

Payload vs. Reach

Depending on where Sawyer is in the workspace and how the end-effector is designed, the combi-

nation of speed, acceleration, reach and payload can have an impact on overall performance of the

robot. We can use Figure D-4 to represent the workspace in terms of speed ratio, acceleration,

reach and payload, unless one of the following conditions is met:

•

The reach of the robot during a task is greater than 1 m;

•

The center of mass of the payload is offset from the J6 axis by more than 10 cm;

•

The payload offset from the J6 axis is greater than 2 kg.

MODE

SETTLING

TIME

(sec)

OVERSHOOT

(mm)

Low

velocity

mode/0

kg

payload

0.3

50

Low

velocity

mode/3.85

kg

payload

0.5

80

Normal

velocity

mode/0

kg

payload

0.2

80

Normal

velocity

mode/3.85

kg

payload

0.2

110

Summary of Contents for Sawyer

Page 15: ...8 Intera 5 3 Getting to Know Sawyer Hardware Overview of Your Robot ...

Page 16: ...9 Intera 5 3 Getting to Know Sawyer Dimensions ...

Page 17: ...10 Intera 5 3 Getting to Know Sawyer Sawyer Reach ...

Page 93: ...86 Intera 5 3 Train Pick and Place Patterns on the Head 11 Press OK to go to the next step ...

Page 104: ...97 Intera 5 3 Train Pick and Place Patterns on the Head You may now run the task ...

Page 134: ...127 Intera 5 3 TCP IP The Set To node in the Behavior Editor is used to output information ...

Page 138: ...131 Intera 5 3 Fieldbus Devices 3 Using a keyboard navigate to CONFIGURATION and press ENTER ...

Page 155: ...148 Intera 5 3 ...

Page 156: ...149 Intera 5 3 ...

Page 180: ...173 Intera 5 3 ...

Page 190: ...183 Intera 5 3 Fixed Data 112 From Robot ...

Page 206: ...199 Intera 5 3 Small Assembly 114 From Robot 115 To Robot ...

Page 207: ...200 Intera 5 3 Large Assembly 116 From Robot 117 To Robot ...

Page 208: ...201 Intera 5 3 Floats 118 From Robot 119 To Robot ...

Page 209: ...202 Intera 5 3 Strings 120 From Robot 121 To Robot ...

Page 218: ...Z Zero G button 16 17 Zero G mode 24 Zero Gravity mode 17 zoom reset 42 ...

Page 219: ......

Page 220: ...Last updated June 18 2018 Intera 5 3 User Guide Getting Started Rev A ...