OPERATING MANUAL FOR

RETIGO

HOLD-O-MAT

7

ver. EN-01/10/12

5.

Operating of Retigo Hold-o-mat 1/1 Standard

(without temperature core probe)

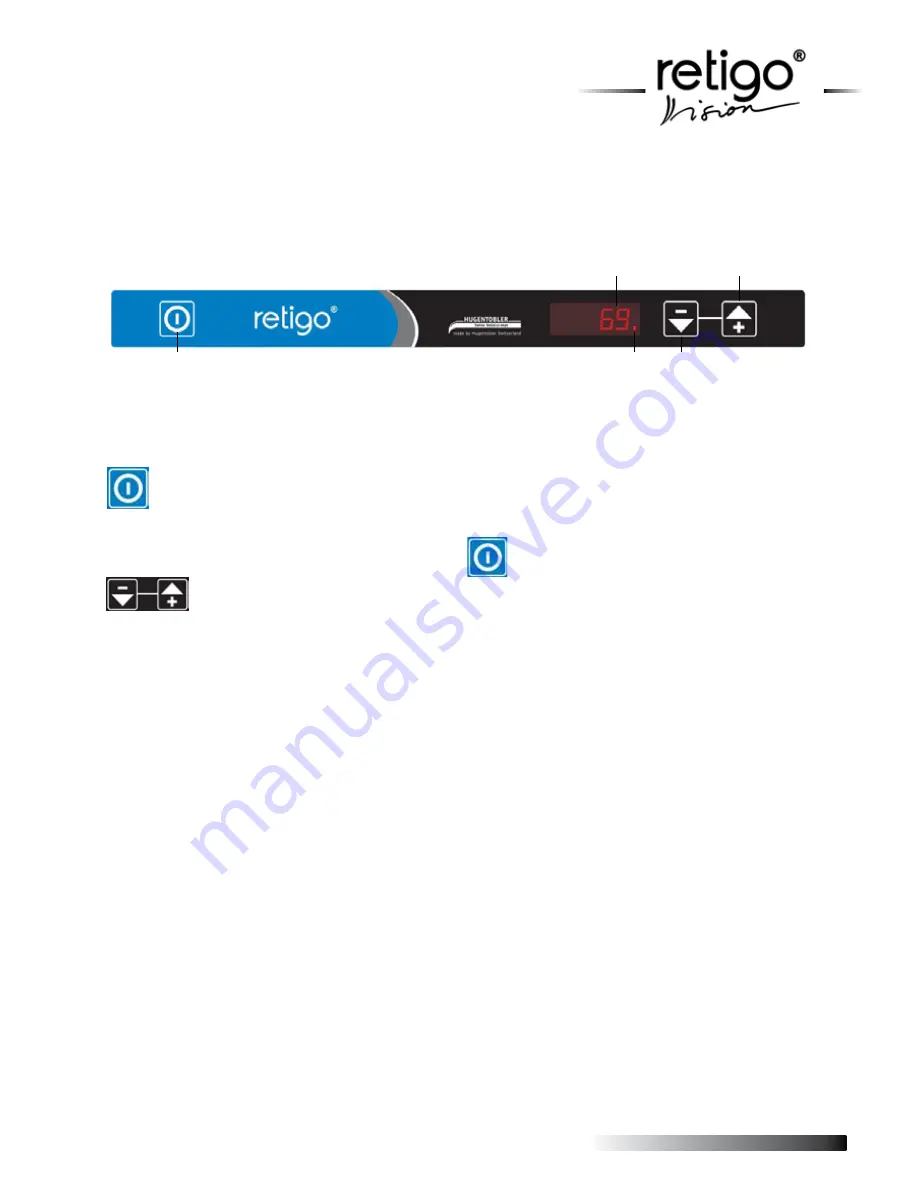

5.1 Control panel

Main switch - on/off

Heat

indicator

Higher

temp.

Lower

temp.

Temp. indicator

5.2 Basic operating instructions

5.2.1 Switching on

-

Press the button to switch on.

5.2.2 Temperature setting

- The indicator always shows the actual

temperature. By pushing an arrow button

once, the desired temperature is displayed for two

seconds. Then the indicator returns to showing the

actual temperature.

By pressing the buttons again while the desired

temperature is displayed, the desired temperature can

be increased or decreased.

Pressing both buttons together automatically sets

the the most important temperature of 68°C. The

desired temperature is reached within 20 to 40 minutes,

depending on what temperature has been chosen.

The Hold-o-mat is designed to respond to this slowly,

but this ensures that the desired temperature is

maintained within a +/- 1°C tolerance.

The warming-up time can be shortened by setting a

higher temperature than actually required. Do not forget,

however, to lower the temperature in time (about

6–10°C below the desired temperature), otherwise the

unit will get too warm.

If the Hold-o-mat exceeds the desired temperature

by 5°C or more, the indicator flashes to warn kitchen

staff. To cool the unit slowly, leave the door open slightly

longer. (Thanks to its excellent insulation, this takes

somewhat longer than with other units.)

The desired temperature can be set to the degree

in a range from 50°C to 120°C. The PT 500 and excellent

electronics, which approach the desired temperature

slowly step by step (a timing pulse system), guarantee

+/- 1°C accuracy.

5.2.3 Switching off

- Press the button to switch the Hold-o-mat off.

Please do not forget to clean the unit after use

as outlined in the section „Maintanance“.

5.3 Technical specification

Model:

Hold-o-mat

Product no.:

673

Power supply:

230V, 50/60Hz, 1 kW

Fuse:

10 A

Storage temperature: 0°C - + 50°C

Ambient temperature: +10°C - + 40 °C

Temperature range:

+20°C - +120 °C

Dimensions (WxHxD): 415 x 343 x 675 mm

Weight:

24

kg

Average power

consumption:

cca. 300 W/h

Equivalent noise level: 70 dB(A)

Safety gap from walls and other equipment at least

10 mm.