FIRST Global Building Guide Created by REV Robotics 2019, Licensed Under CC BY-SA

11

3.2.3

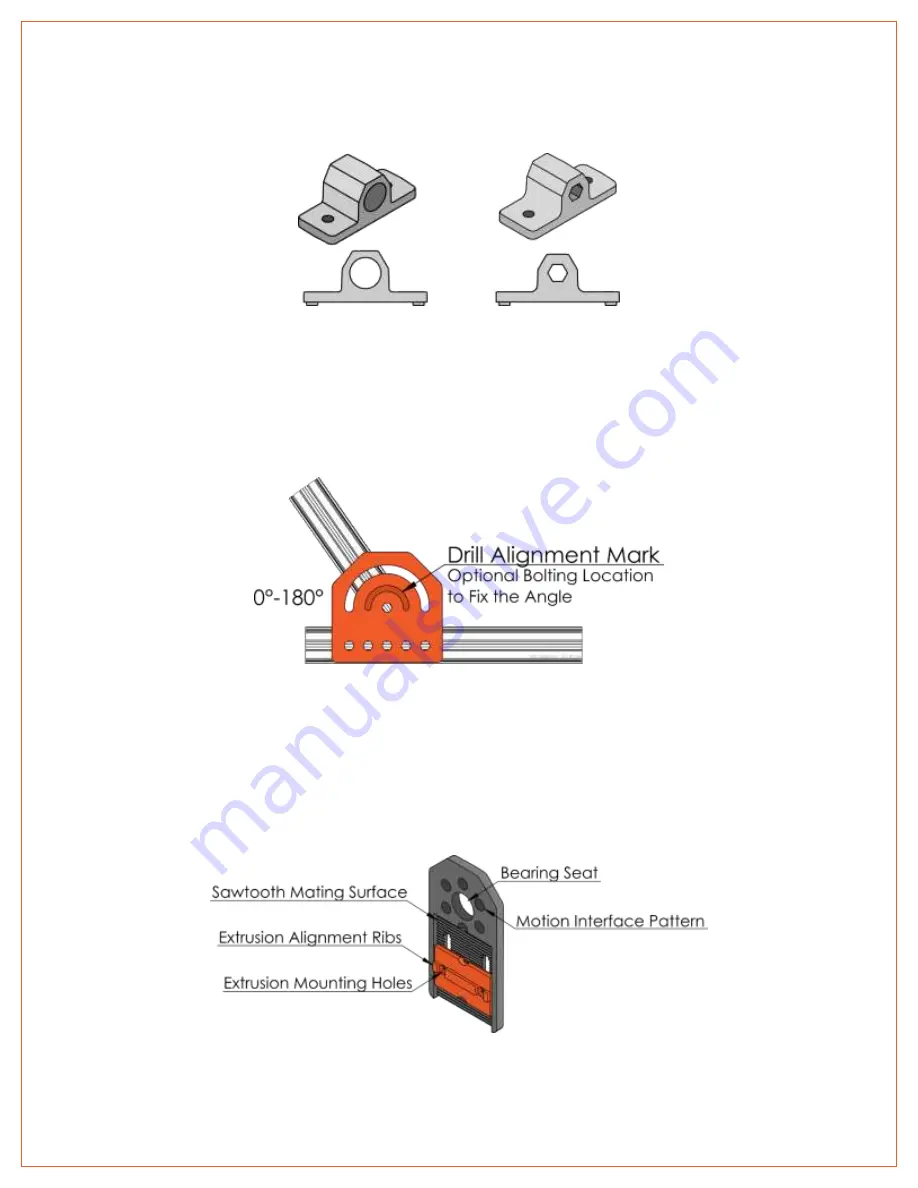

Pillow Blocks

The REV Robotics building system uses plastic nylon (PA66) molded pillow blocks (Figure 15). The bearing pillow block

can be used with the long through-bore or end cap bearings to provide a low friction shaft support. The hex pillow block

directly interfaces with a 5mm shaft which can be used to drive a light duty arm or as a dead (non-spinning) axle support.

Figure 15: Pillow Blocks

3.2.4

Variable Angle Bracket

The variable angle bracket is a special kind of construction bracket which allows 2 pieces of extrusion to be mounted

together at any angle from 0-180° (Figure 16). For additional strength, after the ideal angle has been set, miter the end of

the extrusion which will be connected using the arced slot and drill a hole along the alignment mark arc so that it lines up

with the extrusion channel and add another bolt to stop the angle from changing.

Figure 16: Adjustable Angle Bracket Example

3.2.5

Indexable Motion Bracket

The Indexable Motion Bracket is a specialized version of the Motion Bracket. This bracket is made up of two pieces: the

smaller piece has alignment ribs and fits onto the extrusion, while the larger piece has a motion interface pattern and a

bearing seat (Figure 17). On the inside face, where these brackets meet is a fine sawtooth pattern which mesh when they

are bolted together to hold the shaft offset. To adjust the offset, loosen the bolts and adjust as needed, retighten with the

teeth fully engaged to secure (Figure 18).

Figure 17: Indexable Motion Bracket