FIRST Global Building Guide Created by REV Robotics 2019, Licensed Under CC BY-SA

16

3.4.5

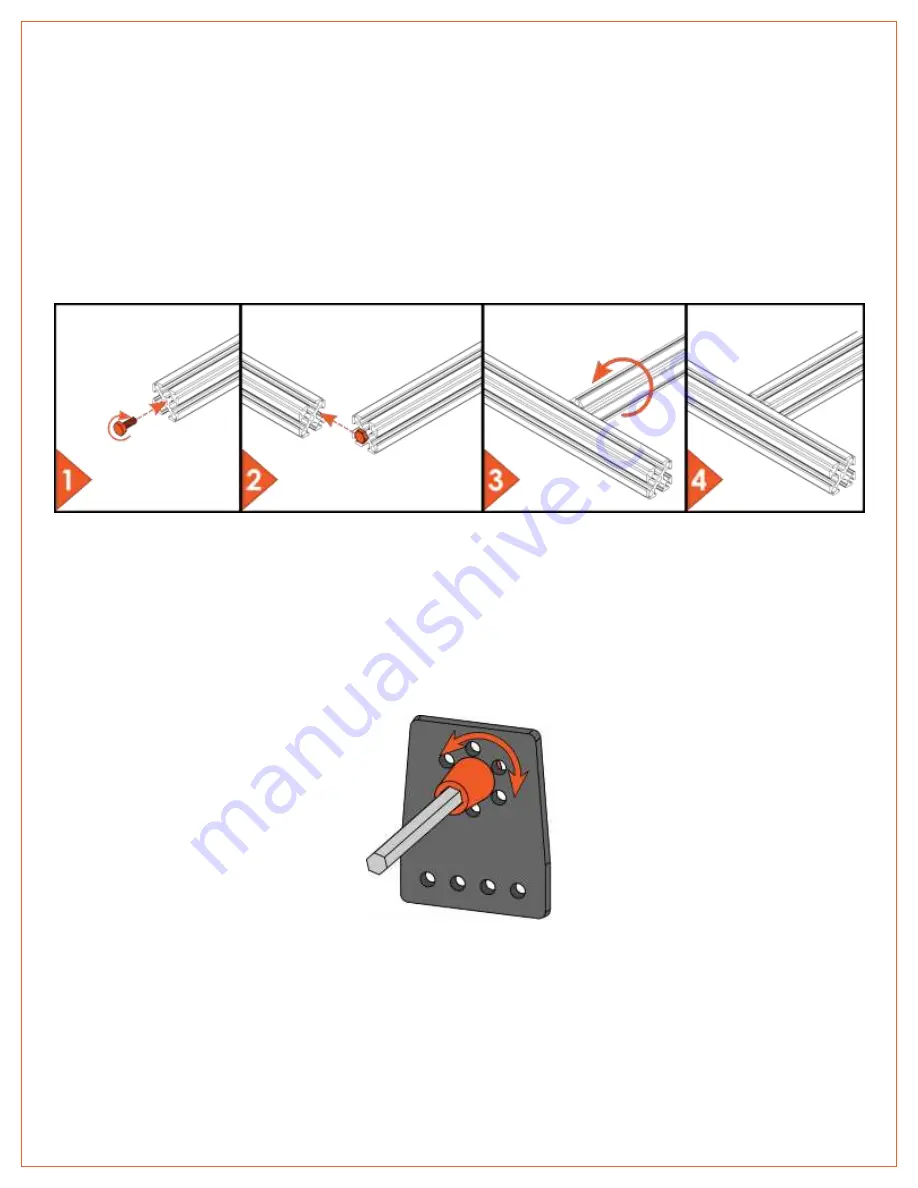

End-Tapped Extrusion Method

The end-tapped extrusion assembly method is good for quick simple structures to verify spacing of a design. This is not a

primary building method and once the correct spacing has been established, a bracket should be added to reinforce the

joint.

1.

Thread the M3 bolt into the center hole on the end of the extrusion. Using a standard driver, the bolt should

self-tap into the end of the extrusion. An actual M3 tapping tool can also be used if desired.

2.

Tighten the bolt until it feels securely threaded into the hole. Leave enough thread exposed that the head can

be slid into the channel of another piece of extrusion.

3.

Slide the extrusion with the bolt in it to the desired location and then turn the extrusion to tighten the bolt.

4.

This joint is sufficient for quick, light duty testing, but brackets should be added when the design is finalized.

Figure 28: Extrusion to Extrusion Quick Joint

3.5

BEARINGS

3.5.1

Molded Plastic Bearings

The REV Robotics Building System uses plastic acetal (Delrin/POM) molded bearings. These bearings have a maximum

9mm outer diameter (OD) which fit inside the 9mm inner diameter (ID) hole in the all the motion brackets (Figure 29).

Figure 29: Plastic Bearing in a Motion Bracket