3

Installation and Operation

Blood Bank Refrigerators

4.5

Door Seal

To check the door seal, complete the following steps:

1. Open the door.

2. Insert a strip of paper (a couple of inches wide) between the

door gasket and the cabinet flange and close the door.

3. Slowly pull the paper strip from the outside. You should feel

some resistance.

4. Repeat this test at 4-inch intervals around the door. If the

door does not seal properly, you need to either replace the

gasket, or adjust the door (see Section 4.4).

CAUTION!

Door seal integrity is critical for blood

bank refrigerators. A loose fitting gasket allows moist

air to be drawn into the cabinet, resulting in quicker

frost buildup on the evaporator coil, longer running

time, poor temperature maintenance, and increased

operation cost.

The door seals on 12 ft

3

models can be adjusted. To correct a

faulty seal on these units, complete the following steps:

1. Open the door completely.

2. Remove the hinge pin cover to expose the door mounting

screws. This cover pops off.

3. Loosen the screws and move the door side of the hinge to

decrease the clearance between the gasket and the cabinet.

4. Tighten the screws and snap the hinge pin covers on.

5. Recheck the seal.

6. If the door does not seal properly, replace the gasket.

4.6

Final Checks

Before start up, complete the following steps:

1. Make sure that the unit is free of all wood or cardboard

shipping materials, both inside and outside.

2. Check the positions of the stainless steel drawers. If you

want to adjust the drawer slides in an Upright unit, follow the

instructions in Section 5.3.

3. Verify that the unit is connected to a dedicated circuit.

5

Drawers

5.1

Removing the Drawers

To remove the drawers in Upright models (23 ft

3

and larger)

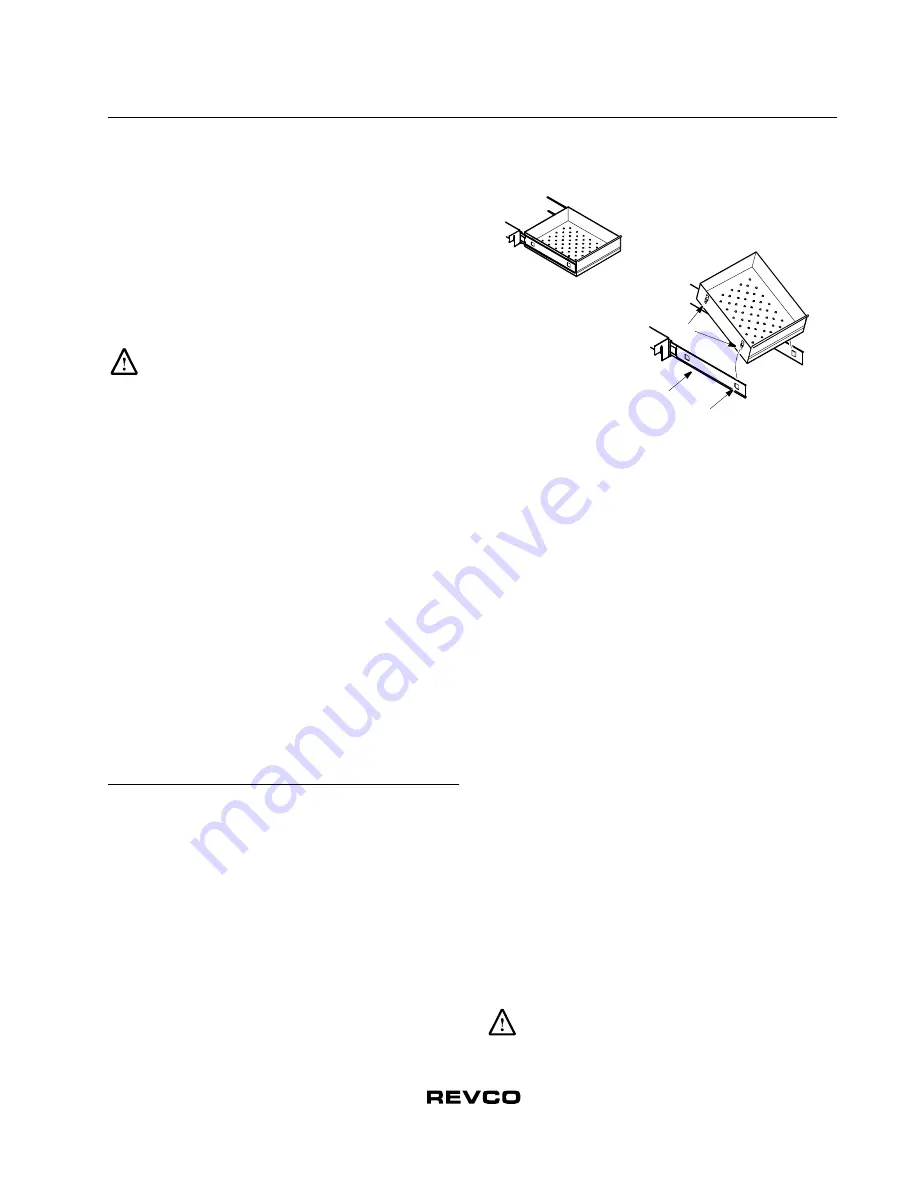

complete the following steps (refer to Figure 2):

1. Pull the drawer toward you until the slides are fully extended.

2. Lift the back of the drawer to disengage the mounting tabs

from the slots on the slides.

Note:

The drawers fit snugly between the slides. Push the back

of the drawer from underneath to remove the drawer.

3. Raise the back of the drawer almost to a vertical position and

disengage the front mounting clips from the slides.

To remove the drawers on Space Saver models, depress the

hooks located on both sides of the drawers (about 1/3 of the way

back) and slide the drawers up and out.

Figure 2. Drawer Removal (Upright Models)

5.2

Reinstalling the Drawers

To reinstall the drawers in Upright models, complete the

following steps (refer to Figure 2):

1. Pull both drawer slides toward you until the slides are fully

extended.

2. Position the drawer between the slides and insert the front

mounting clips into the slots on front of the slides.

3. Push the back of the drawer down between the slides and

insert the drawer tabs into the back slots.

Note:

The drawers fit snugly between the slides. Push on the

back of the drawer from the inside to insert the drawer

tabs completely into the slots. Make sure both drawer

tabs are aligned with the slots on the slides before

pushing the drawer down between the slides.

5.3

Changing Drawer Slide Position

The drawer slides are adjustable. You can position these slides in

the vertical slots which are spaced at one-inch intervals.

Drawer slides have a small wire safety clip at the front pilaster

which prevents the slides from falling when the drawers are

removed. To change the position of the drawer slides, complete

the following steps:

1. Locate the safety clip.

2. Slip your fingernail or a small screwdriver under the bottom

of the wire clip and pry the clip out toward the inside of the

refrigerator.

3. Lift up the slide at the front. The slide is free to move from

the front pilaster.

4. The drawer slide must be removed from the rear pilaster at

approximately a 45 degree angle toward the center of the

cabinet.

5. Pull the slide toward the front of the cabinet.

CAUTION!

Drawer slides do

not

require lubrication.

Additional lubricant could impede movement of the

drawers when the lubricant is cold.

Tabs

Drawer slide

Slot