5

Installation and Operation

Blood Bank Refrigerators

6.2

Display Functions

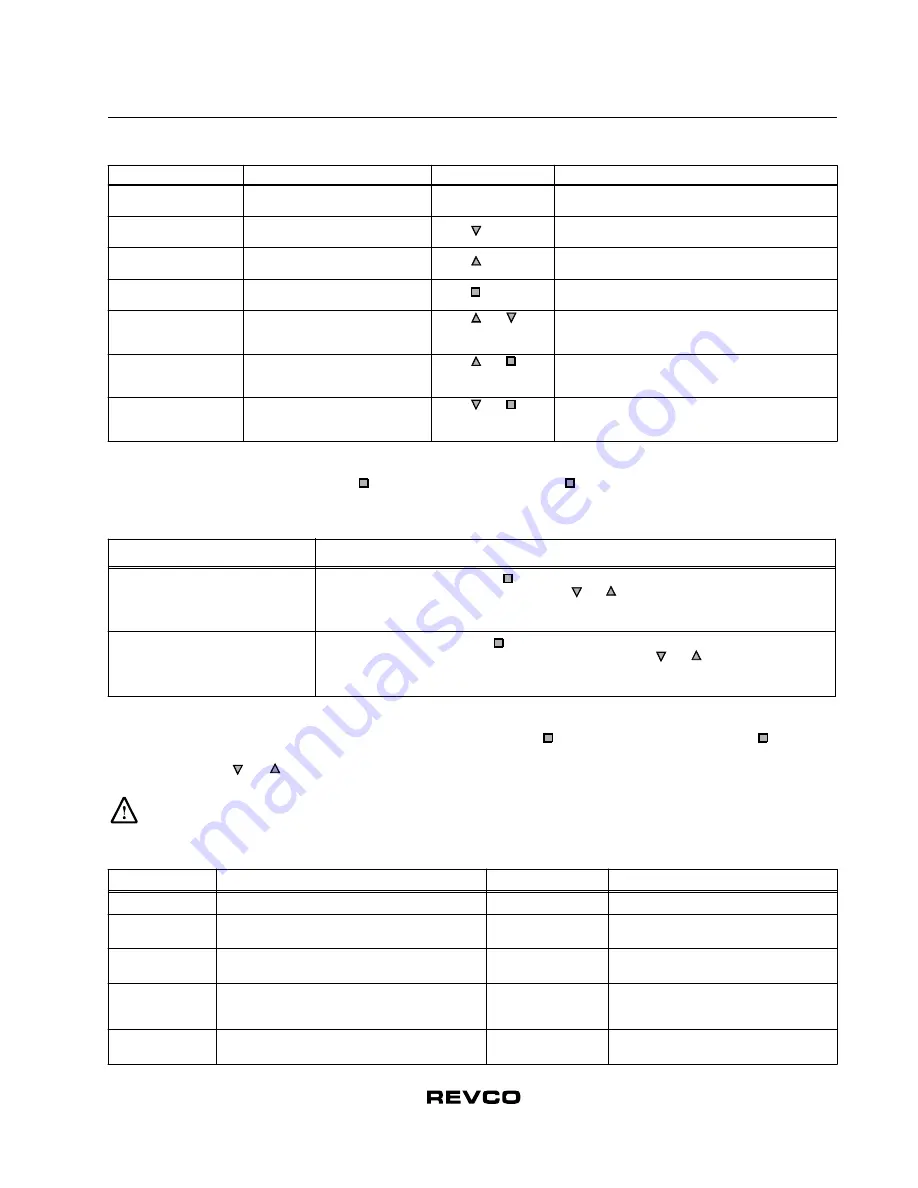

Table 2.

Control Panel Display Functions

6.3

Programming Functions

You can enter programming mode by pressing and holding for 5 seconds. Pressing repeatedly scrolls through the available setpoint

functions: warm alarm and cold alarm.

Table 3.

Setpoint Programming Functions

6.4

Service Parameters

You can access service parameters by entering programming mode and pressing for an additional 5 seconds. Pressing repeatedly

scrolls through the available service functions. While you are in service mode, the wrench icon is illuminated. For any displayed

parameter you can use

and

to adjust the value

.

CAUTION!

Resetting any of the following parameter values could adversely affect the performance of your blood bank

refrigerator. These settings very rarely need to be changed for 4ºC operation. Be sure to call Revco Service before

making any adjustments to service parameter values.

Table 4.

Service Parameters

Function

Meaning

Sequence

Display

Normal operation

Default display while refrigerator

is running

—

Temperature display and thermometer show cabinet

temperature.

Cold excursion

Show coldest cabinet temperature

since last startup or reset

Press

Display shows cold excursion while button is pressed.

Warm excursion

Show warmest cabinet temperature

since last startup or reset

Press

Display shows warm excursion while button is pressed.

Mute

Silence audible alarm

Press

Display and thermometer show cabinet temperature,

alarm icon continues to flash.

Reset

Return to default display after

excursion or alarm condition

Press

and

simultaneously, hold

for five seconds

Excursion values are reset; temperature display shows

cabinet temperature.

Alarm test

Test by simulating warm alarm

conditions

Press

and

simultaneously, hold

for five seconds

Display and thermometer show simulated cabinet

temperature, alarms flash and sound as appropriate.

Display blinks twice when test is completed.

Lower sensor

Display lower cabinet temperature

Press

and

simultaneously and

hold

Display shows lower cabinet temperature while buttons

are held, returns to upper cabinet temperature when

buttons are released.

Function

Programming Sequence

Adjust cold alarm setpoint

Enter programming mode by pressing

and holding for 5 seconds. On release, the current cold alarm

setpoint value flashes in the temperature display; use

and

to adjust it. The display automatically returns

to normal operating mode 30 seconds after the last key entry or after scrolling through both available

functions.

Adjust warm alarm setpoint

Enter programming mode and press

repeatedly until the top of the thermometer is illuminated. The current

warm alarm setpoint value then flashes in the temperature display; use

and

to adjust it. The display

automatically returns to normal operating mode 30 seconds after the last key entry or after scrolling through

both available functions.

Parameter

Notes

Parameter

Notes

1. Offset

Center air temperature calibration. Default value is 0.

6. Defrost Duration

Range 5 to 30 minutes; default value is 15.

2. Line voltage

Display only.

7. Defrost Termination

Temperature at evaporator at which defrost

cycle terminates; default value is 4ºC.

3. Cut On

Cabinet temperature at which compressor starts to

cool down to setpoint. Default value is 5ºC.

8. Short Cycle Delay

Range 0 to 15 minutes; default value is 0.

4. Differential

Offset – differential = temperature at which

compressor stops after achieving cabinet temperature

setpoint. Default value is 2.

9. Control Probe

Temperature

Display only.

5. Defrost Interval

Range 1 to 12 hours; default value is 1.

10. Defrost Probe

Temperature

Display only.