6

Installation and Operation

Blood Bank Refrigerators

7

Operation

7.1

Start Up

To start up the refrigerator, complete the following steps:

1. Plug in the power cord.

2. Insert the key in the switch and turn the power on.

The temperature display has a range of 0 to 11.4

°

C. When the

temperature in the cabinet drops below 11.4

°

C, the display

shows the actual cabinet temperature.

3. Rotate the power switch to the ALARM ON position when

the temperature drops below the warm alarm setpoint.

4. Allow the unit to reach operating temperature before loading

it with any product. To stabilize the temperature profile,

a 24-hour waiting period is recommended.

5. After the unit has pulled down to the desired operating

temperature, turn the three position key switch one turn

further clockwise to the Alarm On position.

6. If you have a remote alarm, hook it up at this point (refer to

7. Whether you have a built-in alarm or a customer-installed

remote alarm, you should test it following the instructions in

Section 9.4 on page 7. Alarm setpoints are factory pre-set for

5.5 and 1.5

°

C.

7.2

Product Loading Guidelines

When loading your blood bank refrigerator, take care to observe

the following guidelines:

•

Never load the blood bank beyond capacity. Table 1 on

page 1 shows the number of 450ml bags that can safely be

stored in your unit.

•

Distribute the load as evenly as possible. Temperature

uniformity depends on air circulation, which could be

impeded if drawers are overfilled, particularly at the top of

the cabinet.

•

For critical applications such as blood storage, be sure that

the alarm systems are working and active before you load

any product.

7.3

Automatic Defrost

The defrosting process on all models is primarily accomplished

by air circulated during off-cycle periods. All models are

equipped with a built-in, on-demand defrost feature which is

preset at the factory. The units defrost only under the most severe

conditions.

Under normal conditions, the temperature warm-up during

defrost is virtually unnoticeable. However, an occasional 2

°

C

warm-up is possible if usage is heavy and ambient conditions are

extreme.

8

Temperature Control

8.1

Setpoint Control

Your individual unit has been adjusted and factory tested to

maintain a +4

°

C cabinet temperature. For blood banks, cabinet

temperature setpoint is a computed value based on the service

parameters Cut On and Differential (see Table 4 on page 5).

For most blood bank applications, however, you will not need to

change the temperature setpoint.

8.2

Sensor Bottles

Cabinet temperature is measured by probes inserted in sensor

bottles. The bottles contain equal portions of glycerine and water

to simulate blood samples. Keep the sensor bottles completely

full up to the top of the bottle.

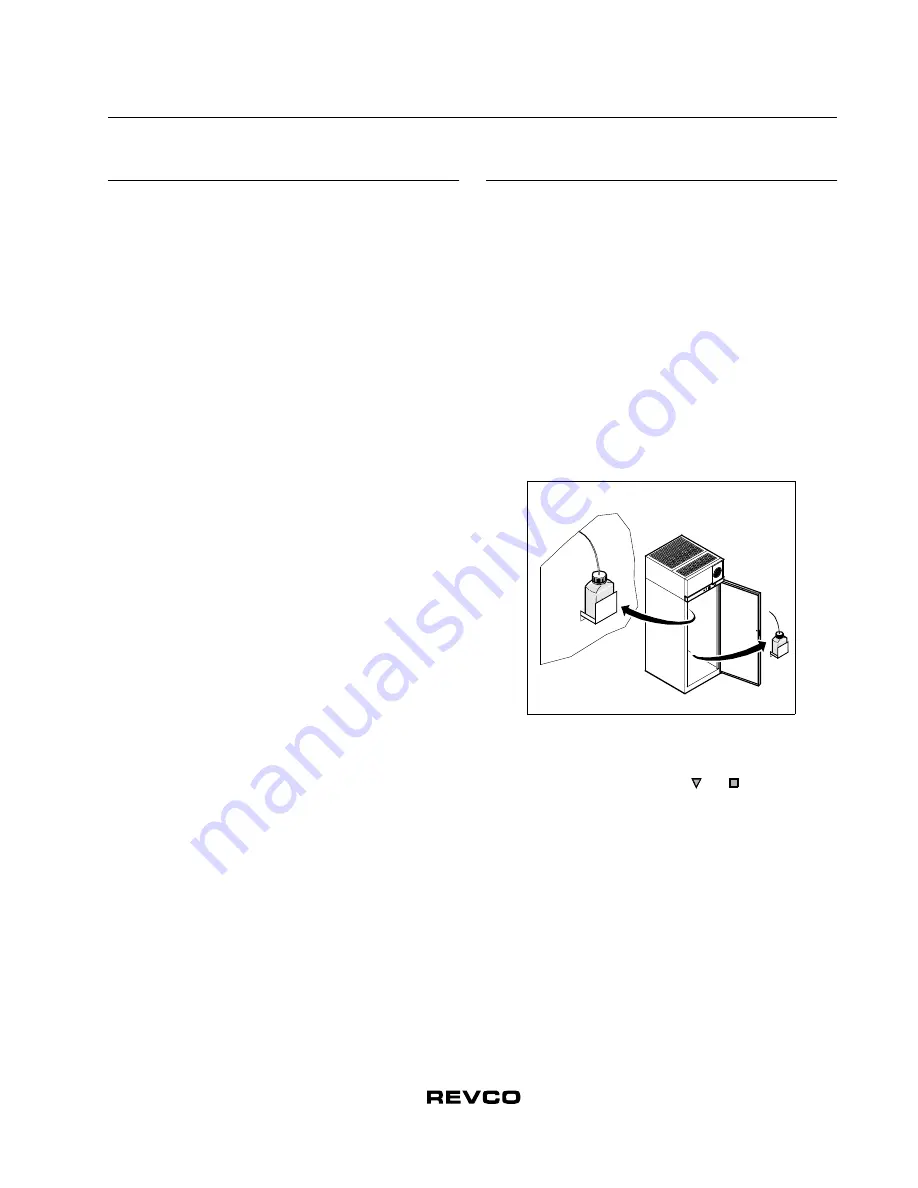

Space Saver models have one factory-installed sensor bottle. In

Upright models (23 ft

3

and larger) there are two sensor bottles,

positioned as shown in Figure 4.

Figure 4. Sensor Bottles (Upright Models)

The default sensor reading for Upright units is the bottle at the

top of the cabinet. You can check the temperature in the lower

sensor bottle by pressing and holding

and simultaneously

(refer to Figure 3 on page 4). When you release the buttons, the

temperature display returns to the upper sensor reading.