STRUCTURAL CONCEPTS TECHNICAL SERVICE CONTACT INFORMATION & LIMITED WARRANTY

SCC Warranty Revision K Date: 12.10.2018

LIMITED WARRANTY

Overview:

All sales by Structural Concepts Corporation (hereafter referred to as “SCC”) are subject to the following limited warranty. “Goods” refers to the product or products

being sold by SCC.

Warranty Scope:

Warranty is for equipment sold in the United States, Canada, Mexico and Puerto Rico. Equipment sold elsewhere may carry modified warranties.

Warranty; Remedies; Limitations:

The limit of liability of SCC toward the exchange cost of the original compressor motor (and/or any other components) is one year parts and

labor. If any Goods are found to be of faulty material or workmanship within one year of the original F.O.B. (free on board) unit shipment, SCC will, at its option (after inspection

by an authorized representative), replace or pay the reasonable cost of replacement of the faulty Goods. If warranty claim is not made within this one year time period, SCC is not

bound to warrant Goods. A motor-compressor (and/or any other components) replaced during the warranty shall not exceed manufacturer's current established wholesaler’s

exchange price. If replacement motor-compressor (and/or other components) is available via storage facility, parts truck, etc., SCC mandates that readily accessible replacement

components be used toward repair of Goods; in such instances, SCC will replace such equipment (at its own expense) after confirmation of its use/placement on defective unit.

SCC shall not be charged an additional fee, up-charge or expense for such replacement Goods. If SCC is unable to repair or replace the defective Goods, SCC shall issue a

credit to the Purchaser for full or partial purchase price, as SCC shall determine. The replacement or payment in the manner described above shall be the sole and exclusive

remedy to Purchaser for a breach of this warranty. If any Goods are defective or fail to conform to this warranty, SCC will furnish instructions for their disposition. No Goods shall

be returned to SCC without its prior consent.

SCC’s liability for any defect in the Goods shall not exceed the purchase price of the Goods. SCC SHALL HAVE NO LIABILITY TO PURCHASER FOR CONSEQUENTIAL

DAMAGES OF ANY KIND WHATSOEVER, INCLUDING, BUT NOT LIMITED TO, PERSONAL INJURY, PROPERTY DAMAGE, LOST PROFITS, OR OTHER ECONOMIC

INJURY DUE TO ANY DEFECT IN THE GOODS OR ANY BREACH OF SCC, SCC SHALL NOT BE LIABLE TO THE PURCHASER IN TORT FOR ANY NEGLIGENT DESIGN

OR MANUFACTURE OF THE GOODS, OR FOR THE OMISSION OF ANY WARNING THEREFROM.

SCC shall have no obligation or liability under this warranty for claims arising from any other party’s (including Purchaser’s) negligence or misuse of the Goods or environmental

conditions. This warranty does not apply to any claim or damage arising for or cause by improper storage, handling, installation, maintenance, or from fire, flood, accidents,

structural defects, building settlement or movement, acts of God, or other causes beyond SCC’s control.

Except as expressly stated herein, SCC makes no warranty, express, implied, statutory or otherwise as to any parts or goods not manufactured by SCC. SCC shall warrant such

parts or Goods only (I) against such defects, (II) for such periods of time, and (III) with such remedies, as are expressly warranted by the manufacturer of such parts of Goods.

Notwithstanding the foregoing, any warranty with respect to such parts of Goods and any remedies available as a result of a breach thereof shall be subject to all of the

procedures, limitations, and exclusions set forth herein.

THE WARRANTIES HEREIN ARE IN LIEU OF ALL WARRANTIES, EXPRESS, IMPLIED, STATUTORY, OR OTHERWISE. IN PARTICULAR, SCC MAKES NO WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

No representative, agent or dealer of SCC has authority to modify, expand, or extend this Warranty, to waive any of the limitations or exclusions, or to make any different or

additional warranties with respect to Goods.

Period of Limitations:

No claim, suit or other proceeding may be brought by Purchaser for any breach of the foregoing warranty or this Agreement by SCC or in any way arising

out of this Agreement or relating to the Goods after one year from the date of the breach. In the interpretation of this limitation on action for a breach by SCC, it is expressly

agreed that there are no warranties of future performance of the goods that would extend that period of limitation herein contained for bringing an action.

Indemnifications:

Purchaser agrees to indemnify, hold harmless, and defend SCC if so requested, from any and all liabilities, as defined herein, suffered, or incurred by SCC as

a result of, or in connection with, any act, omission, or use of the Goods by Purchaser, its employees or customers, or any breach of this Agreement by Purchaser. Liabilities shall

include all costs, claims, damages, judgments, and expenses (including reasonable attorney fees and costs).

Remedies of SCC:

SCC’s rights and remedies shall be cumulative and may be exercised from time to time. In a proceeding or action relating to the breach of this Agreement by

Purchaser, Purchaser shall reimburse SCC for reasonable costs and attorney’s fees incurred by SCC. No waiver by SCC of any breach of Purchaser shall be effective unless in

writing nor operate as a waiver of any other breach of the same term thereafter. SCC shall not lose any right because it has not exercised it in the past.

Applicable Law. This Agreement is made in Michigan; it is governed by and interpreted according to Michigan law. Any lawsuit arising out of this Agreement or the Goods may be

handled by a federal or state court whose district includes Muskegon County, Michigan, and Purchaser consents that such court shall have personal jurisdiction over Purchaser.

LED Lighting Components Within Lighting System:

Supermarket: 5-year LED warranty from date of shipment. Foodservice: 2-year LED warranty from date of shipment. After

one year, warranty does not include labor or other costs incurred for diagnosing, repairing, removing, installing, shipping, servicing, or handling of either defective part or

replacement parts. Remedy of repair or provision of a replacement part without charge shall be the exclusive remedy for any warranty claim. The replacement LED and/or power

supply assumes the unused portion of warranty remaining on unit(s). A 90-day warranty will apply for any LED sold as a service part. Warranty claim must include serial and

model number of unit as well as date code on defective LED lighting component(s). Manufacturer may request return of defective part(s) at customer’s expense to initiate claim.

Glass Material:

Glass (UV-bonded glass, glass sneeze guards, glass enclosures, glass held in place via posts, etc.) is only warranted to FIRST POINT OF DELIVERY.

Miscellaneous:

If any provision of this Agreement is found to be invalid or unenforceable under any law, the provision shall be ineffective to that extent and for the duration of

the illegality, but the remaining provisions shall be unaffected. Purchaser shall not assign any of its rights nor delegate any of these obligations under this Agreement without prior

written consent of SCC. This Agreement shall be binding upon and inure to the benefit of SCC and Purchaser and each of their legal representatives, successors and assignees.

SCC warrants its products to be free of defects in materials and workmanship under normal use and service for a period of one (1) year from the date of delivery.

This warranty is extended only to the original purchaser for use of the Goods. It does not cover normal wear parts such as plastic tongs, tong holders, tong cables, bag holders,

or acrylic dividers.

General Conditions:

All service labor and/or parts charges are subject to approval by SCC. Contact Customer Service Dept. in writing, by phone, fax or email.

All claims must contain the following information: (1) model & serial code number of equipment; (2) the date and place of installation; (3) the name and address of the agency

which performed the installation; (4) the date of the equipment failure; and (5) a complete description of the equipment failure and all circumstances relating to that failure.

Once the claim has been determined to be a true warranty claim by SCC’s Customer Service Department, the following procedure will be taken: (1) replacement parts will be sent

at no charge from SCC on a freight prepaid basis; (2) reimbursement for service labor will be paid if the following conditions have been met - (a) prior approval of service agency

was awarded from the Customer Service Department; and (b) an itemized statement of all labor charges incurred is received by the Customer Service Department. The cost of

the service labor reimbursement will be based on straight time rates and reasonable time for the repair of the defect.

If problems occur with any compressor, notify SCC’s Customer Service Department immediately. Any attempt to repair or alter the unit without prior consent from the Customer

Service Department will render any warranty claim null and void. This warranty and protection plan does not apply to any condensing unit or any part thereof which has been

subject to accident, negligence, misuse, or abuse, or which has not been operated in accordance with the manufacturer’s recommendations or if the serial number of the unit has

been altered, defaced, or removed.

One Year Limit of Liability:

After SCC's one-year parts and labor warranty on the original F.O.B. (free on board) unit has expired, SCC is not liable for either the equipment or

labor costs of repairing or replacing the motor compressor, nor any other components that were included in the original F.O.B. (free on board) unit.

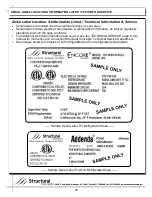

TECH SERVICE/WARRANTY CONTACT INFO:

1 (800) 433-9490 / EXTENSION 1

DAYS/HOURS AVAILABLE:

MONDAY - FRIDAY (CLOSED HOLIDAYS)

8:00 a.m. TO 5:00 p.m. EST

YOU MUST HAVE THE FOLLOWING INFO AVAILABLE

BEFORE CONTACTING STRUCTURAL CONCEPTS:

SERIAL NO. / MODEL NO. / STORE NO. / STORE

ADDRESS / DETAILS (PHOTOS, LEAK LOCATIONS,

DAMAGE, STORE’S AMBIENT CONDITIONS, ETC.)

31