Operation and Maintenance Manual – Steam sterilizers mod. Full Clave

Rev. 01 of 01-12-2006 - C:\Documenti\Manuali di istruzione\FULL CLAVE GB-R01.doc

Page 15 of 34

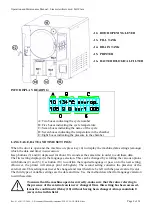

6.3 After work

After the operations have terminated, move the green main switch (17) to position 0 and open the door.

Pay particular attention to the temperature of the various components

when the machine is switched off.

Wait a few minutes to allow them to cool.

7 . H O W

T O

A R R A N G E

T H E

I N S T R U M E N T S

F O R

T H E

S T E R I L I Z I N G

P R O C E S S

Before being sterilized, the instruments must be cleaned to remove blood residues, incrustations,

foreign bodies, etc. These impurities can damage the items being sterilized, the autoclave components

and prevent the sterilizing process from being correctly carried out.

These instruments must be made of NON-ferrous material since they could damage the other

instruments or the autoclave itself.

To achieve perfect sterilizing, it is therefore important to proceed in the following way:

1. Rinse and brush the instruments under running water immediately after use to remove all deposits.

2. Place the instruments in the ultrasound machine with distilled water and detergent solution if

possible.

3. Thoroughly rinse the instruments in demineralised water to prevent scaling stains.

4. Dry the instruments to eliminate all water residues which could lead to oxidation.

5. Wash, rinse and dry the supplied trays and make sure that they are perfectly clean.

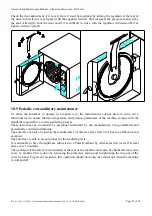

6. To ensure that packaged instruments are perfectly dried, we recommend use of support art. M9050

supplied as an optional.

7. If loose instruments must be sterilized, it is advisable to cover the trays with a paper or fabric

napkin to prevent direct contact with the tray surface: do not place the instruments straight on to the

trays.

8. Scissors and forceps should be slightly opened. Mirrors and containers should be placed upside

down for the sterilizing process.

9. It is advisable to keep the instruments separated from each other to achieve a better sterilizing

action. Overloading will impair the sterilizing process.

10. If packaged instruments must be sterilized on the trays, place the packets with their transparent side

downwards and do not overlap. The packets should not be too large. Drying will be difficult if their

edges overlap.

11. The machine can operate with a maximum 3 Kg load.

Sterilizing handpieces:

Carefully read the handpiece operation manual with particular attention to the part about sterilizing.

Wrap the handpiece in the special sterilizing cloth.

Place the wrapped handpiece on a NON-perforated tray to prevent spilt lubricating oil from

polluting the pipes of the autoclave.

Proceed with a short cycle 121°C sterilizing program.

Remember to immediately remove the handpiece from the autoclave at the end of the sterilizing

process.

For a valid sterilizing process, it is obligatory to add a chemical indicator for each cycle.