Operation and Maintenance Manual – Steam sterilizers mod. Full Clave

Rev. 01 of 01-12-2006 - C:\Documenti\Manuali di istruzione\FULL CLAVE GB-R01.doc

Page 21 of 34

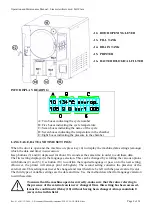

The door has been opened

during the vacuum phase.

Press the START / STOP button before

opening the door.

DOOR OPEN

Door micro defective.

Check, calibrate or replace the door micro.

Power failure in the

electricity main of the

building.

Check to find out whether there are faults in

the electricity main.

The power socket fails to

comply with the standards.

The plug on the machine’s flex must be

plugged into a single socket that complies

with the standards, without reductions or

extensions.

NO POWER

Fuse in the machine burnt-

out.

Replace the fuse and find out why it burnt

out.

9. FAULTS WITHOUT MESSAGES

Faults Causes

Remedies

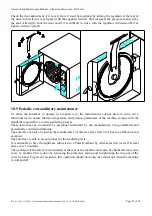

The transparent side of the

packets has been turned

upwards.

The packets must be placed in the chamber

with their transparent sides pointing

downwards.

Too many packets overlapping

each other.

Only as many as two packets can be placed on

top of each other. Use sealer mod. LUX

SEAL code M9025/3.

Trays with less than 400 holes

have been used.

Use trays with at least 400 holes or the gauze

type.

Chamber safety thermostat

activated.

Reset the thermostat in manual mode and find

out what caused the overtemperature.

Bacteriological filter clogged.

Periodically replace the bacteriological filter.

Autoclave positioned on an

unlevel surface.

Use a level when positioning the autoclave.

The drain pipe connected to the

used water tank is clogged or

throttled.

Check the pipe and its connection and replace

them if necessary.

TOO MUCH

HUMIDITY IN THE

PACKETS AFTER

STERILIZING

Bacteriological filter solenoid

valve defective.

Replace the N.C. solenoid valve of the

bacteriological filter.

Door seal defective or

damaged.

Clean and, if necessary, replace the door seal, clean

the seal housing, adjust the door and its pressure.

WATER UNDER

THE MACHINE

Fill and drain tank

connections defective.

Check the connections of the fill and drain tanks.

Too much pressure in the steam

generator.

Calibrate or replace the pressure switch (for the

technician only).

STEAM

ESCAPES FROM

THE SAFETY

VALVE

Safety

valve

defective.

Replace the safety valve and notify the

manufacturer of the serial number of the valve.