Operation and Maintenance Manual – Steam sterilizers mod. Full Clave

Rev. 01 of 01-12-2006 - C:\Documenti\Manuali di istruzione\FULL CLAVE GB-R01.doc

Page 22 of 34

Water inlet filter clogged.

Replace the used water filter and make sure

that there are no residues in the tank.

No water in the clean water

fill tank.

Check and fill the tank if necessary. Check

and clean the tank probes.

Pump defective or worn.

Replace the pump.

WATER FILL PUMP IN

GENERATOR

OPERATES NON-STOP

Clogging in the pipe between

pump and generator.

Clean the pipe that lets water into the

generator.

WATER UNDER THE VENT

Vent seal impaired by foreign bodies.

Replace the vent.

No paper in the printer.

Fit a new roll of paper into the

printer.

NO PRINTOUT FROM

PRINTER

Mechanism defective.

Replace the printer.

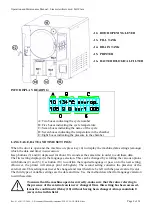

THE MAIN SWITCH COMES ON BUT NOT THE

DISPLAY

Transformer fuse burnt

out.

Replace the

transformer fuse.

Vacuum or water fill pump

defective.

Check operation of pumps.

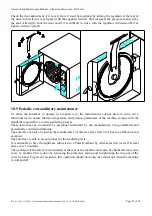

Not all four feet of the machine

are resting on surface.

Shim the feet with rubber or felt washers so

that they all rest on the surface.

TOO MUCH NOISE

WHEN MACHINE

OPERATES

The surface on which the machine

stands is made of metal or is not

too solid and gives rise to

vibrations.

Choose a suitable surface for a dental studio.

Chamber, trays and tray holders

dirty or with residues.

Clean the accessories and chamber

interior.

The material being sterilized is

the ferrous type.

Do not sterilize ferrous materials, only

stainless steel.

The material has been subjected

to lots of sterilizing cycles, or is

of poor quality.

Do not sterilize poor quality material.

The material to be sterilized has

not been packeted or has been

wrapped in damaged packets.

All material that could leave residues

must be packeted. Failing this, use

special trays without holes.

Non-packeted mills and

handpieces.

The instruments have been

wetted with non-demineralized

water.

Do not sterilize material wetted with non-

demineralized water.

INSTRUMENTS

APPEAR STAINED

AFTER STERILIZING

Traces of disinfectant on the

instruments.

Do not sterilize instruments that have

been soiled with disinfectant.

THE PRESSURE IN THE

CHAMBER FAILS TO RISE

ABOVE 1 bar

The relay that powers the

heating elements is

defective.

Check the relay with a tester and replace

it if necessary.