Operation and Maintenance Manual – Steam sterilizers mod. Full Clave

Rev. 01 of 01-12-2006 - C:\Documenti\Manuali di istruzione\FULL CLAVE GB-R01.doc

Page 23 of 34

1 0 .

M A I N T E N A N C E

Carry out maintenance work when the machine is off, with the plug removed from

the power socket and when the various components have cooled down.

The validity of the declaration of conformity to the laws in force will become void

unless the maintenance operations described below are carried out.

10.1 General maintenance

The machine needs to be serviced in a particular way. Users are therefore advised to comply with the

below listed recommendations:

Periodically check the condition of the electrical system with particular attention to the connection

cable.

Contact our Technical Assistance Service or specialized personnel if faults are

discovered.

Periodically clean the door, the seal and take particular care when cleaning the

internal part of the

boiler

, removing any scaling with the damp sponge (supplied with the machine). Correct cleaning

of these parts of the machine will ensure that the sterilizing cycle takes place in the right way.

If the machine is not to be used for a long period of time, leave the door ajar and store it at a room

temperature of >8°C.

Use a damp cloth to clean the casing of the machine. Never ever use inflammable liquids for any

reason whatsoever.

The bacteriological filter must be changed at least once a year. New ones can be ordered with code

1067.

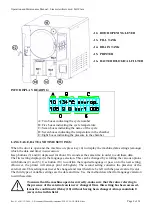

10.2 Daily routine maintenance

Clear the door seal, door window and generally clean the outer and inner surfaces of the machine.

Clean the black silicone door seal, the outer and inner edges and the part where the door rests on the

sterilizing chamber and on which the seal must tightly fit. Use the supplied sponge to do this. The soft

part of the sponge can be used to clean the seal while the rough part can be used to clean the edge of the

chamber.

This cleaning operation must be carried out regularly to remove all impurities that could lead to loss of

pressure inside the sterilizing chamber.

Check the used water level and drain off (14) the actual water into the sewer if necessary. Then wash out

the can under running water.

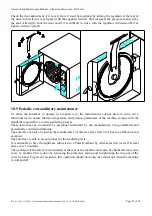

10.3 Weekly routine maintenance

Cleaning the sterilizing chamber (cleaning the trays and tray holders.

As specified in section 10.1 “ General maintenance “, all traces of deposits must be removed from the

bottom of the chamber. Use the rough side of the supplied sponge for this operation, attempting to

eliminate any scaling that may have formed.

Rinse everything with the same water used for the sterilizing process. The trays and tray-holders must

also be cleaned in this way.