Operation and Maintenance Manual – Steam sterilizer mod. Sterilix Baby

Rev. 00 del 03-01-2007 - \\SERVER2012\oo\SETTORE DENTALE\BABY\MANUALI

ISTRUZIONE\Baby GB- R00.doc

Pag. 17 of 26

10.4 Monthly routine maintenance

Lubricate the pins and locking mechanisms.

Check the movement of the hinge and door locking pin. Lubricate with Vaseline oil.

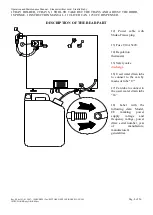

Make sure that the door is well regulated. If it is excessively slack, it must be adjusted by means of the

supplied wrench. Turn the regulator at the rear of the door in a (A) direction. This will increase the

pressure exercised by the seal.

Attempt to shut the door. If some difficulty is encountered, turn the regulator in a (B) direction.

Clean the entire autoclave cabinet with a slightly damp sponge, including the door casing.

10.5 Periodic extraordinary maintenance

To allow the autoclave to operate in a regular way, the manufacturer advises users to carry out a

functional test to ensure that the temperature and pressure parameters of the machine comply with the

standards required for a correct sterilizing process.

These tests must be conducted by personnel authorized by the manufacturer, using calibrated and

periodically certified instruments.

The autoclave can also be sent to the manufacturer for this test, after form page 21 has been filled out

and accepted.

The autoclave is able to accept probes for the sterilizing tests.

It is advisable to have the appliance subjected to a Total Overhaul by After-sales Service staff at least

once every 12 months.

The operation of the safety valve installed at the rear of the machine must also be checked at least once

every 12 months. This is done by removing the protective casing and re-tightening the ring nut of the

valve by hand. To prevent accidents, this operation should obviously be carried out when the machine

is cold and off.