Operation and Maintenance Manual – Steam sterilizer mod. Sterilix Baby

Rev. 00 del 03-01-2007 - \\SERVER2012\oo\SETTORE DENTALE\BABY\MANUALI

ISTRUZIONE\Baby GB- R00.doc

Pag. 3 of 26

1. INTRODUCTION

The machine described in this operation and maintenance manual is a steam sterilizer that has been

specially designed to sterilize most of the materials and instruments used in dental surgeries, doctors'

surgeries and hospitals in general.

The machine can either operate at a temperature of 134°C and a pressure of 2.1 Bar or 121°C and a

pressure of 1.1 Bar. These parameters are monitored and kept at constant levels by three mechanical

and electronic devices that ensure an optimal sterilizing process along with total safety.

The operating cycles can be monitored by means of the pressure gauge, warning lights and by the

position of the controls.

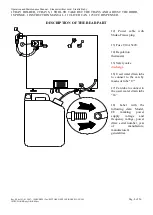

SY

MBO

LS

A

FF

IX

ED

TO

TH

E MA

C

H

IN

E

WARNING: IDENTIFIES A HEAT SOURCE. A PART COULD BE

DANGEROUSLY HOT

WARNING: IDENTIFIES A GENERIC DANGER. THERE COULD

BE A POTENTIALLY DANGEROUS CONDITION

IDENTIFIES THE GROUND CONDUCTOR

Do not use the machine for purposes other than those for which it

has been built.

To prevent the autoclave from being subjected to electrical

disturbance, it is important to make sure that the earth resistance

value is sufficient and well coordinated with the protections in your

electrical system.

This symbol it means the product is covered by the European

Directive 2002/96/EC.

Please inform yourself about the local separate collection system

for electrical products.

Please act according to your local rules and do not dispose of

your old products with your normal household waste. The

correct disposal of your old product will help prevent potential

negative consequences for the environement and human healt.