Operation and Maintenance Manual – Steam sterilizers mod. PRATIKA

Rev. 01 del 03-01-2007 - C:\Documenti\Manuali di istruzione\PRATIKA GB-R01.doc

Pag. 17 di 27

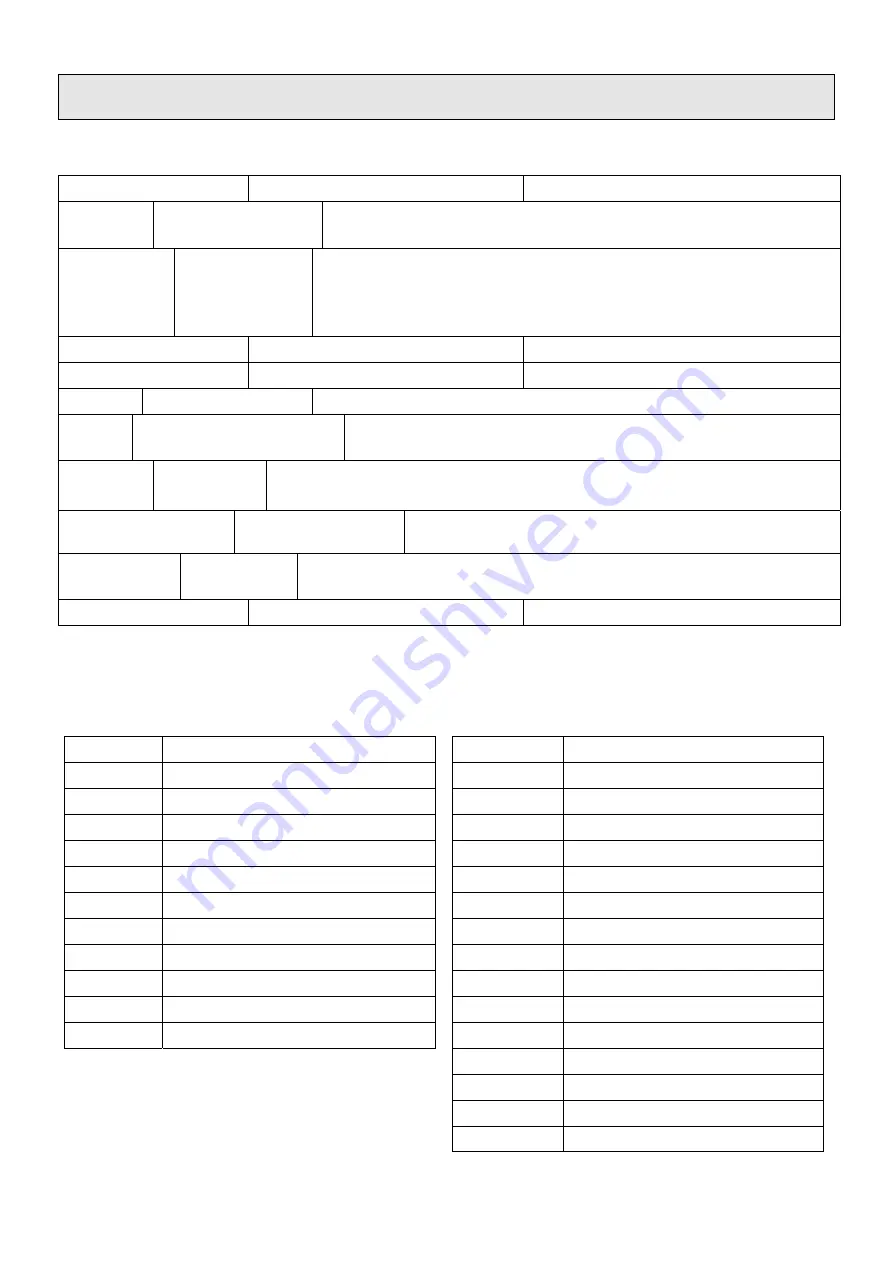

8. MESSAGES DISPLAYED

8.1

Alarm management

MESSAGE ERROR

TYPE

REMEDY

FAILED

Cycle not terminated Check presence of any leaks in the hydraulic circuit, in the door seal

(adjustment), solenoid valve N.O.

NO POWER No mains power Fit the machine plug in a single socket that complies with standards

and is without adapters or extensions. Change the fuse and check the

causes. Make sure the master switch (8) is not turned off with closed

door.

NO WATER IN TANK Not enough clean water in load tank Fill up

BOILER

Boiler level error

Steam generator level probe cleaning

HIGH

High temperature

Check generator solenoid valve and temperature probe cable (PT100)

LOW

Low temperature

Check solenoid valve, thermostat and heating element of

generator.

Clean the generator probe.

VACUUM Vacuum error Check the vacuum pump and the relevant solenoid valve. Check the vacuum

values on the display unit and on the pressure gauge.

MAX TEMP.

High boiler pressure Check the temperature probe (PT100) and cable

or

detached cable.

PRESS. ERR. Pressure error Perform the vacuum test and check for any leaks. Check for any

transducer malfunctions.

U.FULL

Used water tank full.

In case of connection, empty the tank

To reset the machine, turn the switch (8) off and on.

8.2 Operating messages

MESSAGE OPERATION IN PROGRESS

Vac. test

Check hydraulic circuit for leaks

Phials

Pre-sterilised phial culture cycle

Print. Start

No cycle

Maintenance of instrumental drying

Hr. set

Time set

Start time

Start delayed up to 24 hours

Peaks

Vacuum, pressurisation, release

no. cycles

No. of cycle performed by machine

Italian Current

language

(set)

End Cycle

finished

Liquid Liquid

sterilisation (gradual drain)

8.3 Printed Messages

MESSAGE

OPERATION

Ster. time

Sterilisation time

Type of cycle Cycle type

Ster. time

Sterilisation time

Min. Cycle

min.

Sec. Cycle

sec.

Hrs Cycle

hrs.

C Degrees

centigrade

Sterilisation Sterilisation

phase

Pressurisation Steam injection

Drying Drying

stage

End

End of cycle

Total time

Total cycle time

Test Test

cycle

Release Steam

release

Stopped

Cycle stopped by operator