SERENA P GB-R04 del 03-07-17

00/Per Bertani/Manuali d’uso Serena/ Serena con stampante

72/99

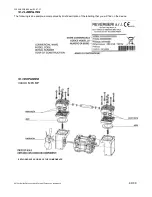

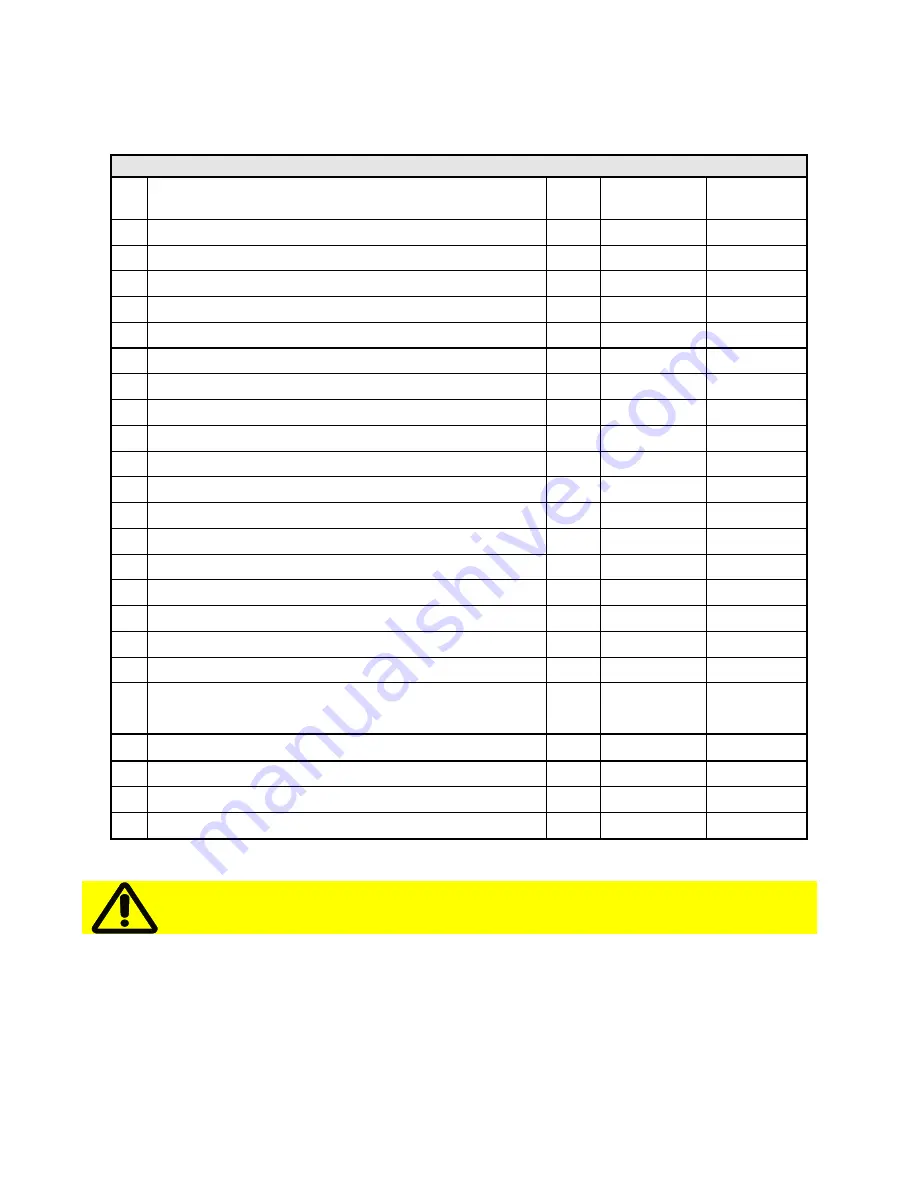

10.2 RECOMMENDED SPARE PARTS LIST

You should keep in your service area for the spare parts the details listed below that in case the sterilizer stops

working, the details below may be useful to the TECHNICAL AUTHORIZED qualified during maintenance, avoiding the

downtime lasts more than necessary, an event that in some cases can cause substantial damage to your business.

RECOMMENDED SPARE PARTS

n°

denomination

quanti

ty

s/n.

s/n.

72omm..le

1 Door Gasket

1

5030

-

2 Bacteriological Filter

1

1067

-

3 Power Cable

1

4404

-

4 Pressure Transducer

1

5125

-

5

Probe Double T1 T2

1

5123

-

6

SD Card

1

4490

-

7

Label Roll

1

K800262

-

8

Float Tank Range

1

3907

-

9

Water Filter

1

1484

-

10 Bowie-Dick Test

1

3606

-

11 Strip Test

1

4263

-

12 Phials Spores

1

4344

-

13 3-Way Complete Valve

1

3246

-

14 Entry fuses

1

1542

-

15 Cartridges for connecting water supply

1

4839

-

16 Vaporizer group

1

5177

-

17 Electro valve group

1

5181

-

18 Load pump

1

5154

-

19 Vacuum pump 18 lt

Vacuum pump 23 lt.

1

1

5104

5237

-

20 Electronic card

1

5189

-

21 Battery of the electronic card

1

5279

-

22

Safety thermostat

1

5093

-

23

Door pin

1

5040

-

Use only original spare parts supplied by the manufacturer!

It is required by those who

perform maintenance to communicate the manufacturer the operations carried out.