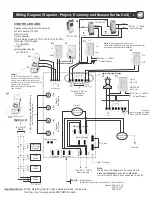

Low

High

Supply

Fan Speed

Exhaust

Fan Speed

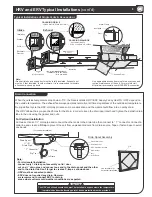

(Fig. 1)

T

emp. Sensor

Low

High

Note:

T

o reduce the air flow turn the Knob

counter clockwise as shown in Fig.1

RERV - S100 AND RHRV - S100A/S100P

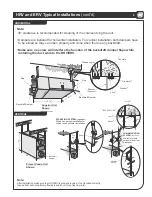

1. Turn the unit off and disconnect the power supply.

2. Unlatch the door and lift the door panel towards you, hold it firmly and slide it to the left.

3. Clean the inside of the

door

and

drain pan

with a damp cloth to remove dirt and debris

that may be present.

4. Clean the

filters:

(twice a year)

-

Remove the filters.

- Vacuum to remove most of the dust.

- Wash with a mixture of warm water and mild soap. Rinse thoroughly and shake filters

to remove water and let dry.

5. Oil defrost damper levers and hinges.

6. Check the exterior fresh air supply hood:

- Make sure there are no leaves, twigs, grass, ice or snow that could be drawn into the vent.

Partial blocking of this air vent could cause the unit to malfunction.

7. Reassemble the components, Filters and Door (The door is secured when you hear a click.)

8. Reconnect the power and turn on the unit.

Regular Maintenance

Maintenance

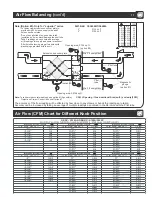

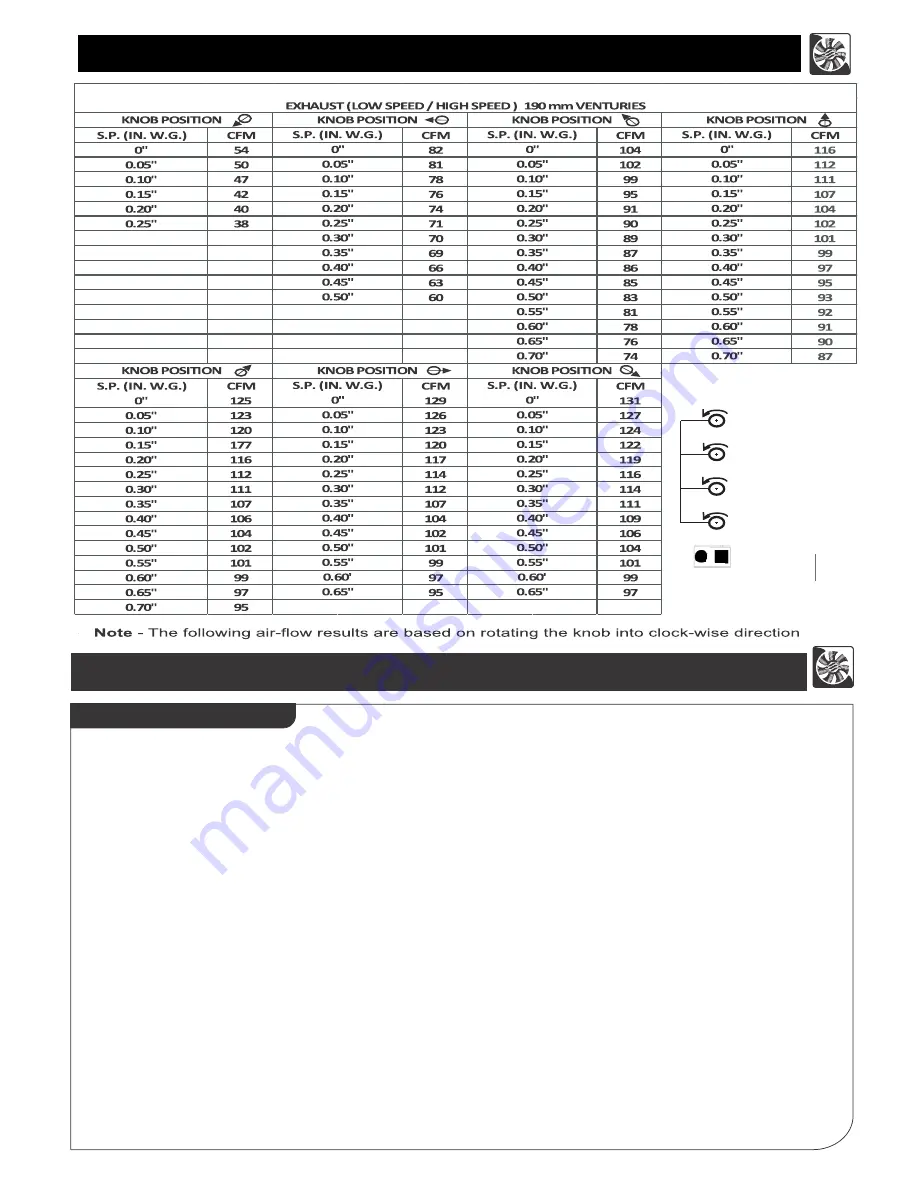

Air Flow (CFM) Chart for Different Knob Position (cont’d)

12