Operating Manual

G

1.

Important

Check the rating plate of the machine corresponds to your electrical supply prior to connection to an easily accessible outlet

socket installed near the unit. This machine MUST be earthed. The mains plug performs the function of the disconnect

device.

2.

Warning!

Overhead transparencies or similar plastic materials must not be fed into this paper shredder. This shredder must not be

subject to temperature/humidity conditions that would cause condensation to occur within the unit.

3.

Operation

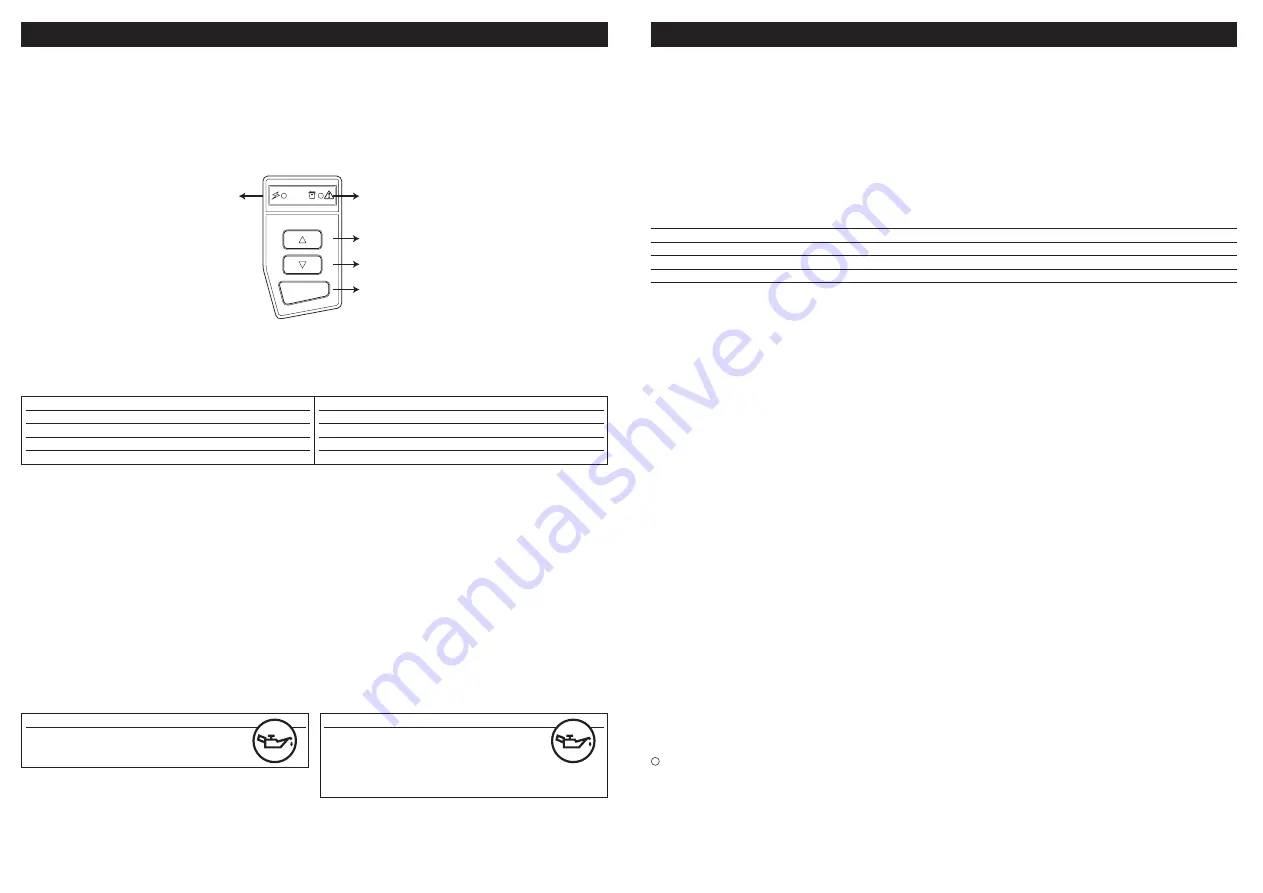

Press the GREEN button and the

light will change from RED to

GREEN. The machine is now in

auto shredding start/stop mode.

4.

Feeding

Feed paper into the shredder paper entry. The electronic eye located in the centre of the feed chute will start and stop the

cutters automatically.

5.

Capacity

The maximum recommended sheet feeding capacity for the models is:

For faster shredding, free from overload interruptions, feed less sheets.

6.

Prolonged Use

It is recommended to allow 30 minutes cool down time for every 15 minutes continuous running time for the 4000 range,

and 45 minutes cool down for every 15 minutes continuous running time for the 1400 range.

If the machine gets too hot, the thermal overload protector device will operate to switch off the motor. Allow a cooling

period before further use.

7.

Paper Overloads

Cutters will stop and the red light will come on if too many sheets are fed in at once. If this occurs, press the RED button to

stop, then the BLUE button to reverse. Separate sheets and re-feed in smaller amounts. If the shredder jams in reverse,

tear off sheets and press the GREEN forward button.

8.

Oiling

Acco Rexel recommends that oil is applied to the cutters of the shredder occasionally, or when there is a significant drop in

performance of the product. We only recommend the use of Rexel branded shredder lubricant to maintain optimum per-

formance and safety. Acco Rexel accepts no liability for product performance or safety if anything other than Rexel branded

shredder lubricant is used. (Order Code 40106).

We recommend these machines are Serviced every 6

months by a Rexel Trained Service Engineer.

GREEN light – auto mode

RED light – stop mode

BIN FULL

Auto

Reverse

STOP

Model

Frequency of oiling

1400s2

4000S26

oil every 5 bin fulls

4000S24

Model

Frequency of oiling

1400s3

1400s4

1400s5

oil every bin full

4000s3

4000s4

Model

Sheets A4 70 gsm

Sheets A4 80 gsm

1400s2

28

25

1400s3

20

18

1400s4

11

10

1400s5

9

8

Model

Sheets A4 70 gsm

Sheets A4 80 gsm

4000s2-6

36

32

4000s2-4

28

25

4000s3

22

20

4000s4

14

12

AUTO

Operating Manual

G

9.

Bin Full

If the Amber light comes on, either compact the waste in the bin, or empty it.

10. Door Open

If the door is open, the power will automatically cut off. All indicator lights will extinguish.

11. Waste Bin/Sacks

The waste bin should be emptied before it is completely full to prevent paper re-entering and damaging the cutters. The

waste sack order numbers are:

AS1000 – 1400 models and AS3000 – 4000 models.

12. Specifications

Noise Level: <70 dBA

Unpacked weights

Packaged weights

Unpacked weights

Packaged weights

1400s2 – 40.7kg

1400s2 – 57.7kg

4000s26 – 58.4kg

4000s26 – 75.1kg

1400s3 – 45.7kg

1400s3 – 62.7kg

4000s24 – 58.6kg

4000s24 – 75.3kg

1400s4 – 44.6kg

1400s4 – 61.6kg

4000s3 – 82.3kg

4000s3 – 98.9kg

1400s5 – 43.8kg

1400s5 – 60.8kg

4000s4 – 84.3kg

4000s4 – 101kg

Motor protection: Thermal overload

Ambient Temperature Operating Range :-

15-25°C 25-75 RH Air Pressure 86-106 kPa

Note - these shredders must not be subject to temperature / humidity conditions that would cause condensation to occur

within the unit.

13. Guarantee

The guarantee period of this machine is listed below:

1400s2 4000s26

1400s3

4000s24

1400s4

4000s3

1400s5

4000s4

The guarantee period starts from the date of original purchase and the manufacturer will provide parts and labour required

to repair the machine should breakdown occur as result of a manufacturing defect.

These guarantees specifically exclude faults or breakdowns occurring as a result of accidental or intentional misuse, fair

wear and tear, or failure to maintain the machine in accordance with the manufacturer’s instructions. Work carried out as a

result of these actions will be charged at the manufacturer’s or approved Service Agent’s rates prevailing at the time of

repair.

This guarantee does not cover:

• Any damage caused during transit,

• The replacement of consumable items such as waste sacks, oil or lost components,

This guarantee does not affect your statutory rights.

14.

Maintenance Contracts

For Service and Maintenance call:

G

Acco Service Division

Freepost 193, Hereward Rise, Halesowen, West Midlands, B62 8AN.

Tel: 0845 658 6600. Fax: 0121 501 3991.

www.acco.co.uk/service

Acco UK Sales International

Oxford Road, Aylesbury, HP21 8SZ. Tel: 00 44 1296 397444. Fax: 00 44 1296 311000

Acco-Rexel Ltd

Clonshaugh Business & Technology Park, Clonshaugh Dublin 17. Tel: 01 816 4300. Fax: 01 816 4302

}

}

2 years parts & additional 3 years, parts only, on cutters

}

}

IRE