DEM Page 32 of 43 FEBRUARY 07

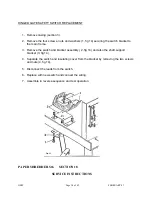

The sensor is mounted on the printed circuit board (PCB) (fig 11b) and detects the high

current drawn when the motor stalls due to the cutting head jamming. The magnetic field of

the wire passing through the coil is sensed by the coil and operates the potentiometer, which

forms part of the logic circuit controlling the contactors which switch the motor.

When jamming occurs, after a short pause, the motor will automatically reverse momentarily

and then stop; the unshredded paper having been returned to the feed chute. The

illuminated controls will now indicate the “STOP” mode. Manual reverse can be obtained by

pressing the reverse button on the control panel to give momentary reverse and then stop.

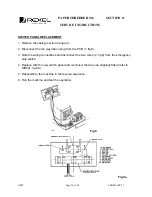

The waste container door is linked to a safety switch which is connected in the logic circuit

and when open also reverts the machine to the “STOP” mode. This condition is indicated by

an illuminated on the switch control panel.

A “Fail-Safe” circuit is incorporated within the logic circuit, to detect any interruption in the

power supply that may cause the machine to suddenly cease working. When the power

supply is restored the machine will automatically be reset into the “STOP” mode.

Machine Not Cutting the Required Number of Sheets

Each machine is set at the factory to achieve the cutting of the maximum number of sheets.

The electrical control is achieved by setting the potentiometer on the PCB (fig 11b). The

electrical setting is checked using the 2-pin test plug located by the potentiometer and

checking the electrical resistance (ohms); compare the value with the factory setting value.

N.B. The setting screw located on the top of the potentiometer is used to achieve adjustment

if necessary. Turning the screw clockwise will increase the maximum number of sheets cut.

Should any other problems be encountered with the electronics, the complete PCB should be

replaced.

PAPER SHREDDER S16 SECTION 14

SERVICE INSTRUCTIONS

Summary of Contents for S16

Page 21: ...DEM Page 21 of 43 FEBRUARY 07 ...