4.

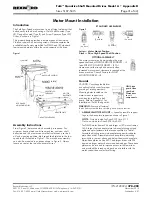

INTERMEDIATE SHAFT ASSEMBLY —

Ref. #2A Assembly

- Type J09, J14 and J25 - Figure 22. Prepare bearings per

Steps 1b and c on Page 18.

a.

ALL SIZES —

Heat gear Ref. #1A4 to 325° (163°C) in

an oven. Insert key, Ref. #2A4, in shaft keyway.

Assemble gear onto shaft, with the chamfer toward

pinion, using a press to ensure a tight fit. Allow gear to

cool before proceeding.

b. Assemble spacer, Ref. #2A6, onto intermediate shaft

(except Sizes 5307 and 5315). Seat bearings or cones,

Ref. #2A1 & 2A2, on shaft. Seat all components firmly

so spacers do not rotate on shaft.

CAUTION:

Allow assembly to cool. Apply a coat of oil to

the cooled bearings to lubricate and avoid scoring of the

working surfaces.

5.

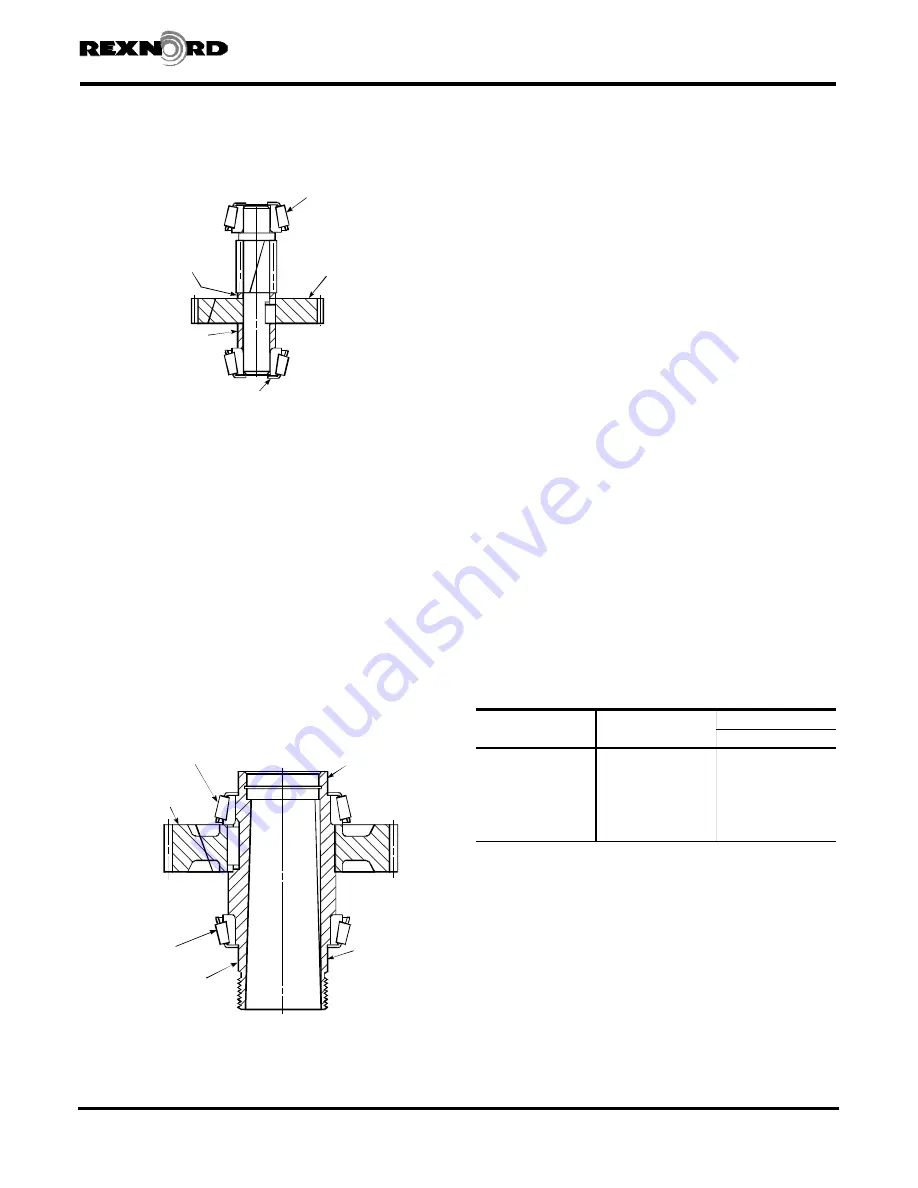

LOW SPEED SHAFT ASSEMBLY —

Ref. #4A Assembly -

ALL TYPES - Figure 23. Prepare bearing cones per Steps 1b

and c.

a. Heat gear, Ref. #4A4, to 325°F (163°C) in an oven.

Insert gear key, Ref. #4A5, into hollow shaft keyway.

Assemble the gear with the chamfer toward the shoulder

on the shaft using a press to ensure a tight fit.

WARNING:

Exercise care so that the gear keyway does

not contact the shaft seal diameter(s) as scoring could

occur.

b. Seat bearing cones, Ref. #4A1 & 4A2, firmly against

gear and shoulder.

CAUTION:

Allow assembly to cool before proceeding.

Apply oil to the cooled bearing rollers and gear teeth to

lubricate and avoid scoring of the working surfaces.

6.

BEARING ADJUSTMENT

a.

SIZES 5107 THRU 5315 —

Bearing adjustment is

made by adjusting thickness of metal shims, Ref. #24,

behind bearing cups in input housing, Ref. #10.

NOTE: The thickest shim should be located adjacent to

the bearing cup. The thinnest shims should be located in

the center of the shim pack.

(1) Support input housing, such that when high speed

shaft assembly, Ref. #1A or 3A, is lowered into place

there is clearance for shaft extension end. Install

bearing cups in input housing without any metal

shims. Tap dowel pins into input housing with solid

pin nearest high speed shaft bore.

(2) Lower low speed shaft assembly, Ref. #4A, into input

housing, Ref. #10, with threaded end facing up.

(DO NOT install Ref. #1A [or 3A] or 2A shaft

assemblies at this time.)

(3) Assemble output housing, Ref. #11, to input housing.

Install housing flange fasteners, Ref. #25, with heads

of cap screws against input housing. Cross tighten

fasteners to torque specified in Table 14.

(4) Measure low speed shaft axial float with a dial

indicator, in accordance with method described on the

following page..

Rexnord Industries, LLC 3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA

(PN-2128394)

378-200

Telephone: 414-342-3131 Fax: 414-937-4359

November 2010

e-mail: info@rexnord.com web: www.rexnord.com

Supersedes 6-07

Falk™ Quadrive Shaft Mounted Drives Model A

•

Owners Manual

Sizes 5107-5315

(Page 19 of 44)

1A4

GEAR

2A1 BEARING

2A5 SPACER

2A6 SPACER

2A2 BEARING

Figure 22

4A2 BEARING

4A3 HOLLOW SHAFT

4A4 GEAR

4A1 BEARING

SHAFT SEAL

DIAMETER

SHAFT SEAL

DIAMETER

Figure 23

TABLE 14 — Housing Flange Fastener Size &

Tightening Torque ±5%

(Non-Lubricated Fasteners)

DRIVE SIZE

Fastener Size

Tightening Torque

lb-ft ( Nm)

5107

.312-18

19 (26)

5115

.312-18

19 (26)

5203

.375-16

27 (37)

5207

.500-13

67 (91)

5215

.500-13

67 (91)

5307

.500-13

67 (91)

5315

.500-13

67 (91)