Introduction

The following instructions apply to INSTALLATION ONLY of internal

backstops in horizontal drives, Sizes 5107 thru 5215 single and

double reduction and Size 5307 & 5315 double reduction.

CAUTION:

If backstop is to be replaced, the high speed shaft

must also be replaced. Refer to instructions regarding high

speed shaft replacement, Section

III

.

Remove all external loads from system before servicing drive or

accessories, and lock out starting switch of prime mover.

Lubricant

PETROLEUM BASED LUBRICANTS —

Use R & O type

lubricants which do not contain anti-wear(AW) additives if the

drive is equipped with an internal backstop.

CAUTION:

Do not use EP lubricants, lubricants with anti-wear

additives or lubricant formulations including sulfur, phosphorus,

chlorine, lead derivatives, graphite or molybdenum disulfides in

drives equipped with internal backstops. Refer to Appendix A for

proper selection of petroleum based lubricants. Use of an

improper lubricant will contribute to premature wear or

malfunction of the backstop.

SYNTHETIC LUBRICANTS —

Synthetic lubricants of the

polyalphaolefin type may be used in drives with internal backstops.

Before installing backstop, check direction of free rotation

(overrunning) indicated by the arrow etched on each side of the

backstop.

Backstop Application

Backstops are designed to prevent reverse rotation or backrun

without backlash in applications such as conveyors, bucket

elevators, fans, rotary pumps and kilns. Backstops are not

approved for use on systems that are designed for handling of

people such as elevators, manlifts, ski tows and ski lifts. DO

NOT use a backstop as a substitute for a brake.

Indexing

DO NOT use the backstop for indexing applications. The

backstop is designed to prevent reverse rotation five times or less

in eight hours, with one minute or more in overrunning direction

between backstopping load applications. If backstopping

operations are more frequent, or the time between operations is

less than one minute, the backstop is classified as an indexing

device and must be referred to the Factory.

Installation

(Backstop Added to Existing Drive Only)

1.

DRIVE PREPARATION:

Drain oil from drive. Remove

fasteners Ref. #27, end cover Ref. #23, and gasket Ref.

#16, Figure 1. Keep Size 5115J and 5207J end covers,

Size 5207J fasteners and all lock washers for reuse, all

other parts may be discarded.

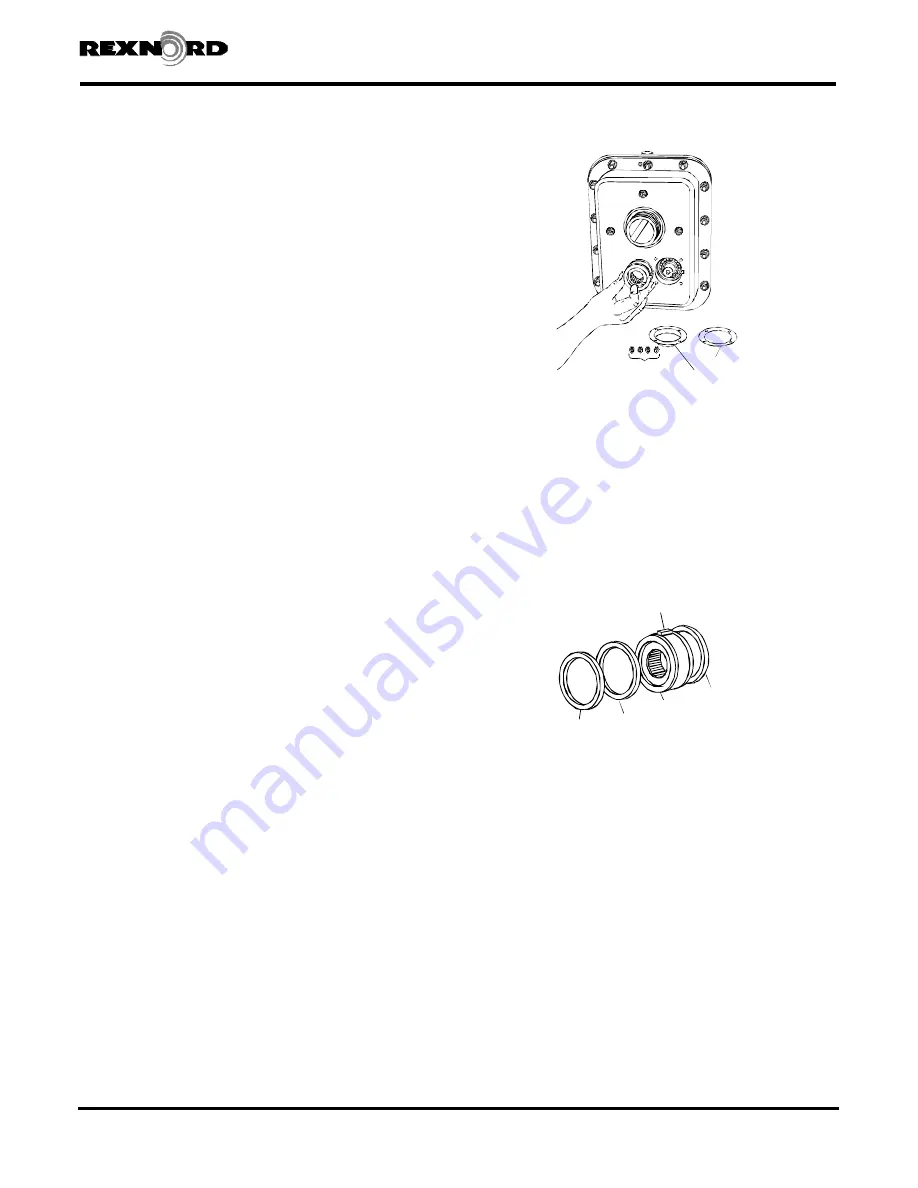

2.

BACKSTOP PREPARATION:

Remove backstop Ref. #5A1

from the kit and wipe off any excess lubricant. On drive sizes

5107 (all ratios) and 5115 (24.87 ratio), assemble retaining

ring Ref. #5A2 onto one of the grooves on the backstop OD.

On drive size 5115J25, assemble spacer Ref. #5A6 to

backstop OD adjacent to retaining ring on inboard side. All

other size 5115J and larger drives, insert housing spacer Ref.

#5A3 (retaining ring used as housing spacer on drive size

5207J) into housing bore adjacent to bearing cup (Figure 2).

Assemble key Ref.#5A4 to backstop keyway (spacer Ref. #5A6

is between retaining ring and key on 511J25 backstop).

3.

ALL SIZES — BACKSTOP INSTALLATION:

Apply oil to

the O.D. of the high speed shaft backstop journal and the

sprags inside of the backstop. Align the backstop key with

the keyway in the exposed housing bore and carefully slide

the backstop into the bore while slowly rotating the high

speed shaft. The shaft will only rotate in one direction. DO

NOT FORCE OR HAMMER; this may damage the shaft or

misalign the sprags.

Check operation of backstop by turning high speed shaft in

required direction of rotation by hand. If the shaft does not

rotate in the required direction, remove backstop, reverse

it, reposition the retaining ring and spacer (where used)

and reinsert it into the housing bore as instructed.

Rexnord Industries, LLC

(PN-2128394)

378-200

3001 W. Canal St.,Milwaukee, WI 53208-4200 USA Telephone: 414-342-3131

November 2010

Fax: 414-937-4359 e-mail: info@rexnord.com web: www.rexnord.com

Supersedes 6-07

REF. #23 GASKET

REF. #16

SHAFT COVER

REF. # 27

FASTENERS

Figure 1

Backstop Installation

Falk™ Quadrive Shaft Mounted Drives Model A

•

Appendix B

Sizes 5107-5315

(Page 27 of 44)

REF. #5A4

REF. #5A2

DRIVE SIDE

REF. #5A1

REF. #5A6

SHAFT

COVER

SIDE

REF. #5A3 SPACER

(5115J25 ONLY)

Figure 2