Falk

™

Drive One

®

Enclosed Gear Drives

•

Appendix D

Type D Series

•

Sizes M1130 thru M1210

(Page 17 of 27)

Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200

168-050

Telephone: 414-342-3131 Fax: 414-937-4359

January 2019

e-mail: info@rexnord.com web: www.rexnord.com

Supersedes 04-11

(PN 2124650)

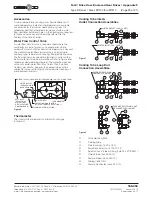

Alignment-Free Assembly and Installation – Welded Design

Introduction

The Alignment-Free drive design consists of a shaft-

mounted drive, bell housing, motor adapter plate, torque

arm, motor and coupling. When assembled, the bell

housing, motor adapter, and motor locate off registers,

resulting in alignment of the motor and gear drive shafts.

Therefore, no additional alignment is required for the high-

speed coupling.

Assembly Instructions

The bell housing is fastened to the drive’s high-speed end

using cap screws through the four mounting holes on that

face (see Table 1 for size and torque). The bell housing will

locate on the bevel head of the drive. Read instructions

provided with high-speed coupling prior to assembly.

Table 1 — Tightening Torques

Drive

Size

Bolt

Size

Tightening Torque

N-m

lb-ft

M1150

M24

725

535

M1160

M24

725

535

M1170

M30

1450

1070

M1180

M30

1450

1070

M1190

M36

2530

1866

M1200

M36

2530

1866

M1210

M36

2530

1866

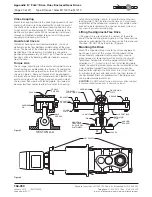

MOUNTING

POST

LONG

CAP SCREW

DRIVE

FAN

SEGMENT

FAN

ADAPTER

RING

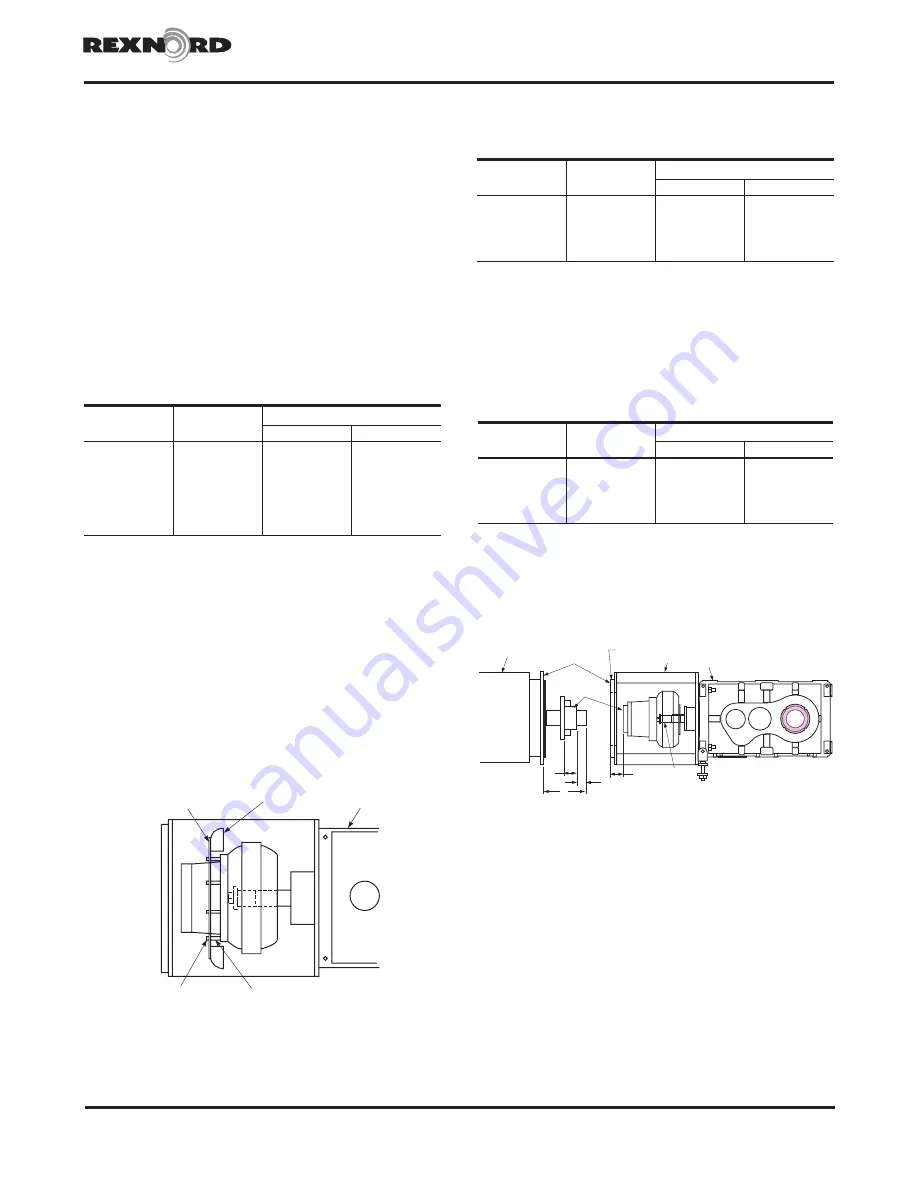

Figure 1

Table 2 — Fan Mounting Tightening Torques

Fastener

Location

Fastener

Size

Tightening Torque

Nm

ft-lb

1420HFDD

M12

80

59

1480HFDD

M12

80

59

1584HFDD

M14

130

96

Fan Segment

M8

20

15

Fan Hub

‡

M6

10

7.5

‡ For close coupling only.

Table 3 — Coupling Gap

Fluid Coupling

Size

Tschan Hub

Size

Gap

mm

Inch

370HFDD

200

6.5

0.256

1420HFDD

230

7.5

0.295

1480HFDD

260

7.5

0.295

1584HFDD

300

8.4

0.331

1660HFDD

360

9.0

0.354

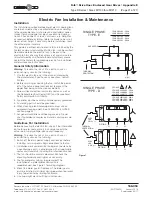

MOTOR

MOTOR

MOUNTING

FACE

MOTOR

ADAPTER

PLATE

BELL

HOUSING

DRIVE

SHAFT

SPACER

PROTRUSION

B

A

C

COUPLING

HUBS

Figure 2

Fluid Coupling

Location of the fluid coupling on the high-speed shaft of

the drive is determined by the provided shaft spacer. Install

the fluid coupling on the high-speed shaft of the gear drive

per fluid coupling instructions. If a shaft fan is required,

remove every other of the twelve delay fill chamber

fasteners. Install the fan adapter ring to the fluid coupling

using the long socket head cap screws provided. Place a

mounting post between the delay fill chamber flange and

the adapter ring as shown in Figure 1. After all fasteners

and mounting posts are installed, tighten cap screws to

the torque specified in Table 2. Install the six fan segments

to the outer bolt circle of the adapter ring. See Table 2 for

tightening torque.

Once the fluid coupling is installed, the motor adapter plate

can be mounted to the bell housing, also being located

by a register. Measurements must be taken to accurately

position the motor half of the coupling hub on the motor

shaft. First, measure the distance from the motor mounting

face to the end of the motor shaft (A). Then measure the

distance from the motor adapter plate face to the hub on

the fluid coupling (B). Finally measure the distance from

the hub flange to the hub end (C). The desired gap can

be found in Table 3, based on coupling size.

Calculate the hub protrusion:

Protrusion = (A + Gap) – (B + C)

If the calculated protrusion is a negative value, the hub

overhangs the shaft by that amount (Figure 2).

Once the hub is correctly located on the motor shaft, the

motor can be mounted to the motor adapter plate. The

hubs will be aligned and come together to the proper gap.

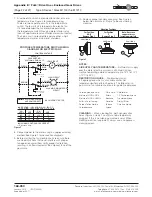

To fill the fluid coupling to the proper oil level, align the

mark on the perimeter of the fluid coupling with the mark

in the center of the inspection window on the bell housing

on the side opposite the TA bushing nut or shaft extension.

To locate the correct mark on the fluid coupling, begin by

aligning the fill hole of the fluid coupling with the mark in

the inspection window. For fill angles less than 90°, rotate

the fill plug upward until the marks line up. For fill angles

greater than 90°, rotate the fill plug downward until the

marks line up. When the proper marks are in line, fill the

fluid coupling with recommended fluid until fluid appears

at the lip of the fill hole.