Commissioning 49/76

CytroPac, RE 51055-B/02.2021,

Bosch Rexroth AG

8.1.3 Bleeding the entire hydraulic system of the machine

For further information, refer to the operating instructions of the machine/system

manufacturer.

▶

Bleed the hydraulic system at the highest point of the hydraulic components.

8.1.4 Flushing the hydraulic system

▶

Flush the hydraulic system to achieve a defined cleanliness of the hydraulic

fluid. This prevents faults and simultaneously increases the life cycle of the

components.

▶

Make sure that the minimum requirements of the cleanliness class for the

components are fulfilled after installation of the hydraulic power unit into the

machine and after integration into the hydraulic system.

Hydraulic systems in general industrial applications require a cleanliness class of

20/18/15 according to ISO 4406; hydraulic systems that include servo valves or

premium high-response valves make greater demands on the cleanliness class,

e.g. 19/16/13.

Observe the cleanliness requirement of the components according to the

manufacturer data sheets for definition of the targeted condition after flushing.

Preparations:

• Provision of replacement or flushing filter elements

• As required: Provision of additional pipe and flexible hose material for flushing and

short-circuit links

• Provision of flushing plates, alternatively directional valves

• As applicable: Provision of flushing fluid (see notice below)

The same medium can be used as in later operation of the hydraulic system. If a

different hydraulic fluid is used, it must be compatible with the operating medium

intended for the hydraulic system and with materials and particularly the seals used

in the hydraulic system. A maximum admissible residual amount (e.g. 0.5 percent by

volume) of flushing fluid in the operating medium can be defined (see manufacturer's

specifications). In this case, this must be ensured by thorough draining of the

flushing fluid prior to filling with operating medium.

In case of comprehensive hydraulic systems with ring and branch lines, detailed

planning of the flushing procedure and thorough processing is required.

The following instructions refer to flushing with the hydraulic power unit described

in these operating instructions.

For use of a separate flushing unit, the respective operating instructions must be

observed!

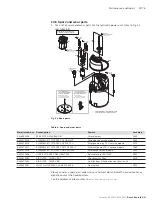

Required material

Information on flushing

fluid