52/76

Maintenance and repair

Bosch Rexroth AG

, CytroPac, RE 51055-B/02.2021

▶

Carry out the following visual inspections for clearly apparent defects:

– Illegible notices or warning signs

– Leakage

– Loose and/or missing parts

– Indications of external force effects

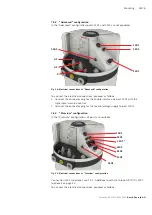

10.3 Warning devices

The "Advanced" and "Premium" configurations of the hydraulic power unit are

equipped with an LED strip for status display:

• Normal operation:

LED strip illuminated in green

• Warning:

LED strip illuminated in green and flashing yellow

• Error:

LED strip illuminated in red and flashing yellow

Warnings and error displays are realized via the flashing sequence of the LED strip:

For a detailed description of the blinking codes, see commissioning instructions RE

51055-IB in chapter 11.2 “Status LED“.

The exact error message may be read out via the Mini USB service interface and

software or IndraWorks Ds.

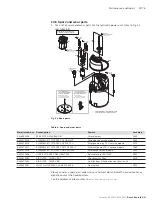

10.4 Maintenance schedule

Observe the status display for oil filter, oil level, oil temperature and oil change of

the LED strip at the hydraulic power unit.

Table 7: Maintenance schedule

Activity/maintenance interval

1/2 y.

1 y.

Alternative:

Operating hours

Visual inspection

External leakage, cracking, force effect, corrosion (oil

tank, flexible hoses, fittings, central plate)

X

Check

Electrical components/installation

X

Check

Pressure values

X

Check (oil sample)

Quality control of the hydraulic fluid

X

1

Replacement

Return flow filter element

X

1

Visual inspection/replacement

Filler breather filter

X

1

Change

Hydraulic fluid

20,000

1)

These components/substances or materials are subject to natural wear. It is therefore very

important to permanently check the components' condition. If necessary, these components are

to be replaced outside the maintenance intervals.