Easy Start Guide

Page 9

This guide has been produced by The Inverter Drive Supermarket Ltd.

All content, including but not limited to graphics, text and procedures copyright

The Inverter

Drive Supermarket and must not be reproduced or altered without prior written permission.

©

Bosch Rexroth EFC 5610 Series Inverter

9. How to connect and configure a Potentiometer

for remote speed control

Parameter

Description

How to set

b0.00

Access to additional parameters

Default is 0 for Basic Parameters. Set to

to enable Advanced Parameters.

2

E0.00

Frequency Setting Source

Default is 0 for keypad dial; set to

for terminal (remote) control via AI1.

2

E1.35

AI1 input mode

Default is

for 0-10V; default is required for this example.

2

9.1 Relevant parameters for remote Potentiometer speed control

If the integrated dial on the keypad is

unsuitable for the application, a remote

Potentiometer can be used instead.

This provides the benefit of allowing motor

speed to be controlled from a more convenient

location such as a cabinet door (if the EFC

5610 is cabinet-mounted) or on the machine

itself.

A Potentiometer of

rating should be

used.

10kOhm

The number of turns depends on the

application but both single turn and ten turn

Potentiometers are available from The Inverter

Drive Supermarket at InverterDrive.com.

If the rotation of the Potentiometer is the

opposite to that required (ie. turn anti-

clockwise to increase speed instead of

clockwise) reverse conne10V and

GND.

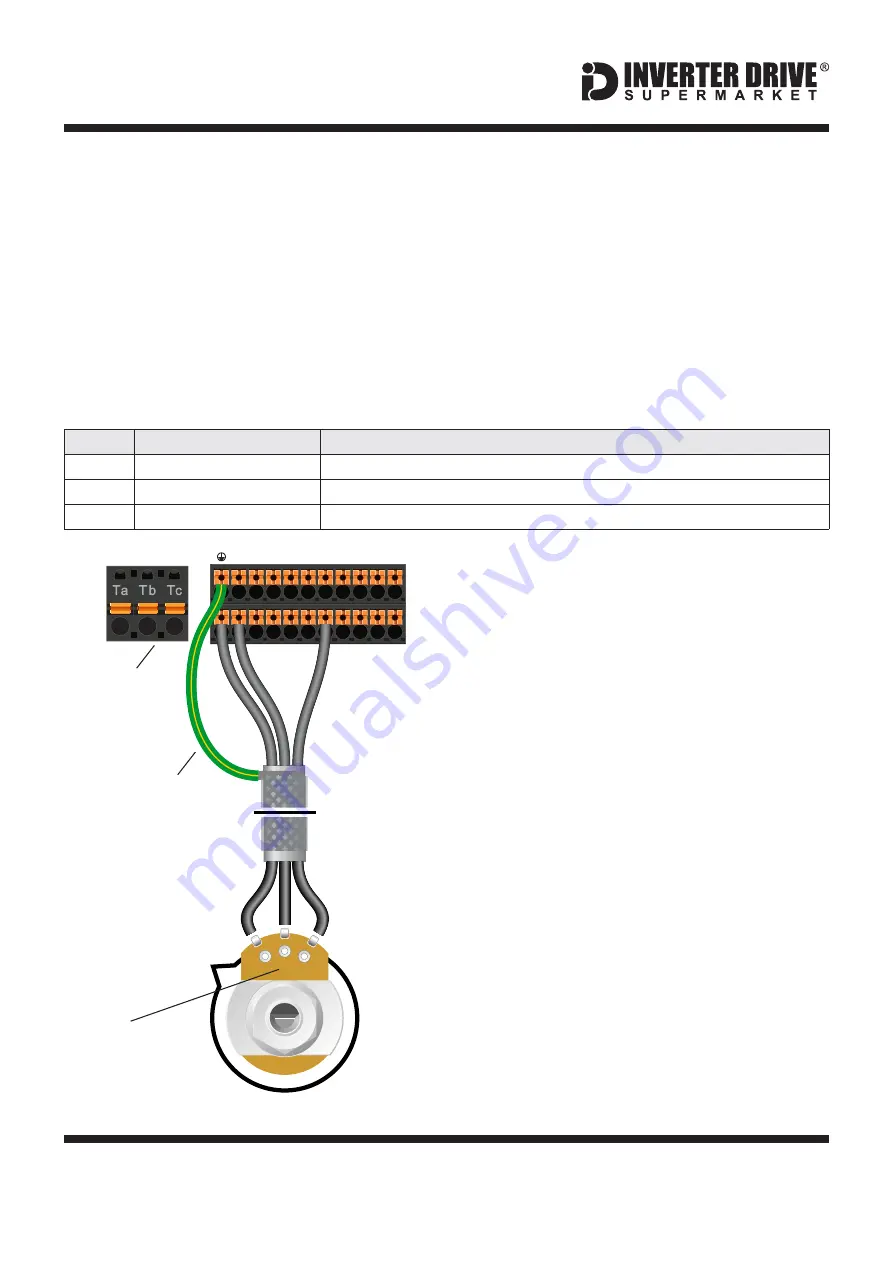

A wiring diagram is shown in the illustration

opposite. The most important connection at

the Potentiometer end is the centre terminal or

“wiper”.

The wiper will output a variable voltage

between 0 and 10 volts and should be

connected to the AI1 terminal at the Inverter

end. It is this voltage which provides the speed

signal with 0V being slowest and 10V fastest.

Use shielded cable between Potentiometer

and Inverter and ensure that the cable screen

is connected to the Inverter earth terminal only.

9.2 Connecting the Potentiometer

The default output frequency at 0V is 0Hz and

at 10V is 50Hz.

2

1

3

10kOhm

Potentiometer

[Order Code 21302]

Cable

Screen

GND

+10V

AI1

EFC 5610

I/O Terminal

Blocks

2

3

1