HLR Braking Resistors and DC Bus Resistor Units HLB

High temperatures in the proximity of braking

resistors!

NOTICE

Mount the braking resistors to temperature-resistant mounting surfaces in

such a way that the air can freely enter and escape and heat does not accu‐

mulate.

Take the minimum distances d

top

, d

bot

and d

hor

into account.

Take into account that the temperatures in the range of the indicated mini‐

mum distances can be above 250 °C.

Leave sufficient distance to combustible objects and take into account that

braking resistors dissipate a lot of heat.

Make sure there is free cooling air supply at the bottom d

bot

and cooling air

discharge at the top d

top

.

The space must be able to discharge the energy converted by the braking re‐

sistor.

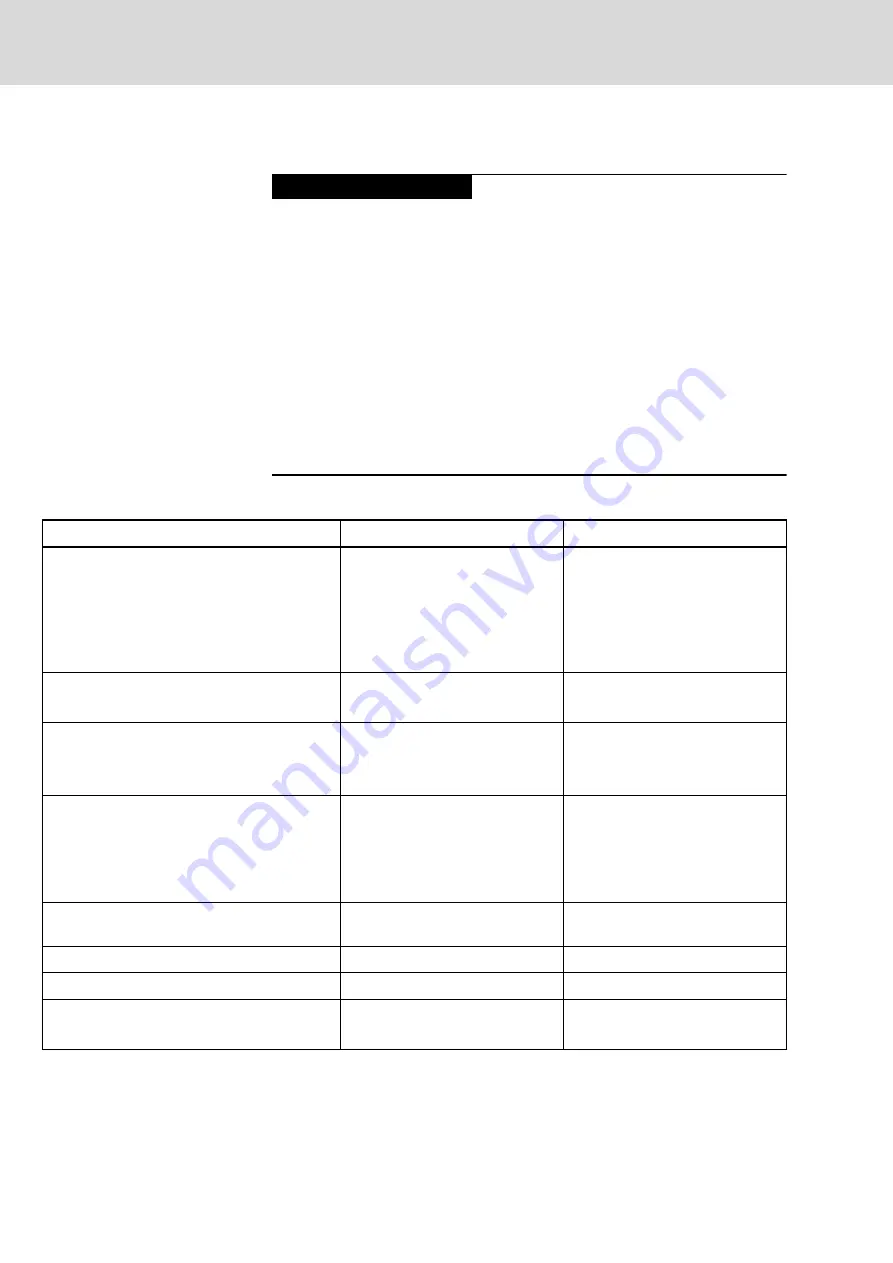

Selection Aid for Additional Components HLR, HLB

Criterion

DC bus resistor unit HLB

Braking resistor HLR

Regenerative operation with great energy con‐

tents, e.g.

●

Deceleration of great centrifugal masses

at centrifuges

●

Long braking processes for crane lifting

gears

□

Take energy absorption capacity

and continuous power into account

■

Type of construction N

Check use of HMVxx.xR

Kinetic energy is generated in control cabinet

and can be dissipated

■

□

Type of construction A

Kinetic energy cannot be dissipated in control

cabinet

-

■

Type of construction N

Observe degree of protection

Quick discharge of DC bus required

■

DC bus short circuit device

Observe the note "Risk of fire

caused by the "sacrificing behavior"

of the ZKS stage!"

-

Deceleration of synchronous motors in the case

of error "mains failure"

■

-

Supply unit HMV01.1R-W0120

■

-

Converter HCS02 selected

■

■

Converter HCS03 selected

■

■

Option -xxBx required

■

Recommended

□

Suited to a limited extent

-

Not allowed

Tab.8-15:

Selection Aid

Bosch Rexroth AG

DOK-INDRV*-SYSTEM*****-PR06-EN-P

Rexroth IndraDrive Drive Systems with HMV01/02 HMS01/02, HMD01, HCS02/03

122/309

Configuring the Drive System